Sports Jersey Manufacturers: IT, Q, X, and Sustainability Insights

inside the global of sports competition, the jersey is not most effective the armor of athletes but additionally a image of emblem image and the spirit of sports. The sports activities jersey manufacturing industry is on the core of this area, and its improvement is carefully linked to market call for. this article will delve into more than one dimensions of the sports jersey manufacturing enterprise, from the production process and fabric technology to marketplace demand, pleasant manipulate, and social obligation and environmental measures, aiming to portray a comprehensive view of the industry and its destiny development trends.

Industry Overview: Overview of Sports Jersey Manufacturing

The sports activities jersey production enterprise, as an essential factor of the sports goods zone, has been increasingly more prosperous in latest years with the thriving improvement of sports. This enterprise encompasses the complete manner from layout, manufacturing to sales, offering expert and relaxed jersey products for numerous sports occasions and lovers.

In terms of layout, sports jersey producers need to hold up with the cutting-edge fashion tendencies and integrate the ideas of sports activities technological know-how to make certain that the jerseys are each aesthetically appealing and practical. Designers have to have a deep understanding of the needs of various sports activities tasks, including basketball, football, volleyball, etc., to provide professional custom designed jersey solutions.

inside the production system, sports activities jersey manufacturing involves a couple of degrees, which includes slicing, sewing, dyeing, and warm stamping. The combination of superior automatic gadget and professional people ensures production efficiency and product great. moreover, manufacturers additionally want to cognizance on environmental safety and sustainability, the use of environmentally pleasant materials and processes to reduce energy consumption and pollution all through production.

material and era are the important thing to ensuring jersey nice. fabrics, green dyeing era, and solid stitching methods collectively shape the muse of sports jerseys. for example, the usage of breathable polyester fibers and Lycra can effectively beautify the comfort of the jerseys; even as expert printing generation can ensure the durability and readability of the patterns.

market call for and trends show that as purchaser call for for customization and functionality increases, the sports activities jersey production industry is growing in the direction of diversification and specialization. high-give up customization, group customization, and sports style are growing niche markets, bringing new increase points to the industry.

great manipulate and certification are critical in establishing industry requirements for sports jersey production. manufacturers have to make certain that every jersey meets relevant requirements thru strict excellent control systems. acquiring international authoritative certifications, together with ISO and GOTS, is also a key to improving emblem photo and competitiveness.

In case studies, a few a hit sports activities jersey manufacturers have emerge as paragons of the enterprise with their extremely good product great and brand have an impact on. as an instance, a brand has received client prefer with its progressive designs via non-stop innovation.

concerning sustainability, the sports activities jersey manufacturing industry is actively taking over social responsibility, specializing in environmental protection and inexperienced manufacturing. From uncooked material procurement to the disposal of manufacturing waste, manufacturers are striving to lessen their effect on the surroundings. for example, measures along with the use of biodegradable materials, optimizing production approaches, and enhancing useful resource utilization intention to achieve a win-win scenario among financial advantages and environmental protection.

The sports activities jersey manufacturing industry is constantly riding the enterprise forward with its expert, streamlined, and objective fashion, presenting sports gadget for international sports fans.

Production Process Analysis: From Design to Finished Product

during the design section, sports activities jersey producers first behavior marketplace research to research the call for traits of different sports projects, making sure the adaptability of the jerseys. Designers check with sports activities technological know-how records and integrate fashion factors to create jersey styles that meet each capability and aesthetic requirements.

in the material selection section, appropriate fabrics are chosen based totally at the practical requirements of the jerseys. The material have to possess breathability, quick-drying properties, elasticity, and durability. The material supplier should offer substances that meet environmental standards to make sure the safety of the finished jerseys.

all through the cutting method, expert cutters as it should be reduce the numerous elements of the jerseys in keeping with design drawings and standards of human engineering. The cutting procedure have to strictly adhere to requirements to ensure the accuracy of the finished product dimensions.

sewing is a crucial step inside the manufacturing system. manufacturers use advanced sewing gadget and follow the prescribed manner to stitch the reduce cloth components together. at some stage in the sewing technique, attention is paid to instantly traces and sturdy seams to make certain the overall beauty and durability of the jersey.

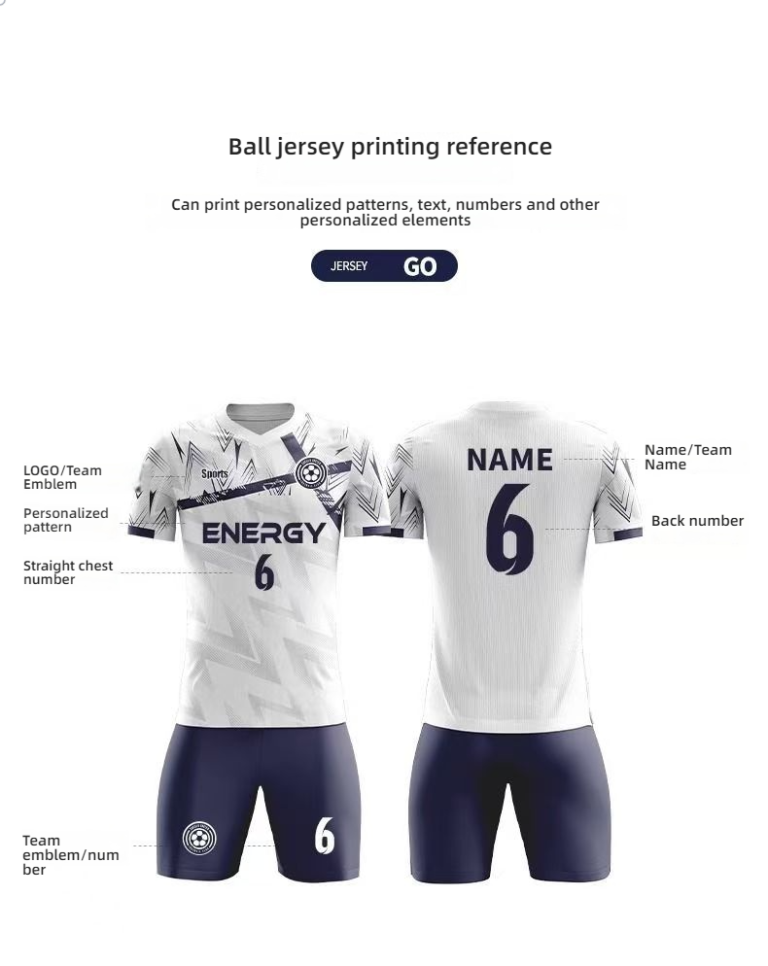

The printing phase includes using professional printing techniques to use styles and logos to the jersey layout. for the duration of the printing system, interest is given to colourful hues and clean layers to make sure the visible enchantment of the completed jersey.

very last product inspection is the final line of protection in ensuring product exceptional. Inspectors conduct strict great checks on each jersey, which includes look, dimensions, capability, and durability. Non-compliant finished merchandise are back to the manufacturing line for remodel.

within the packaging segment, standardized packaging strategies are followed to categorize and package the qualified jerseys. The packaging container is designed to be aesthetically appealing whilst ensuring the protection of the product in the course of transportation.

Logistics distribution is the very last phase of the manufacturing technique. manufacturers collaborate with logistics corporations to supply the products to the client. all through the logistics manner, emphasis is located on protective the product and ensuring timeliness, in order that customers can receive their merchandise directly and be satisfied with them.

at some point of the whole production system, sports jersey manufacturers awareness on unique control, strictly controlling every level from design, fabric selection, to very last product inspection. thru clinical control and superior technology, they ensure that each jersey meets the wishes of athletes and affords a very good wearing experience.

Materials and Technology: The Key to Ensuring Jersey Quality

inside the production of sports jerseys, the selection of substances and the application of era are the middle factors ensuring first-rate. under is a detailed evaluation of this technique:

The jersey fabric is a key element without delay affecting comfort and sturdiness. jerseys usually use high-performance artificial fibers or herbal fabrics, which includes polyester, nylon, cotton, and wool. those substances provide correct breathability, moisture-wicking abilties, in addition to capabilities like anti-creasing, anti-mould, and easy wash-fast drying. whilst choosing the fabric, one ought to remember the jersey’s intended use, which includes the intensity of the game and climatic situations, to determine the most suitable material.

In terms of cloth processing, advanced dyeing techniques are essential. the usage of reactive dyes permits for greater colourful and durable colors which are less prone to fading. moreover, pre-shrinking remedies can lessen the shrinkage fee of the jersey, ensuring dimensional stability. additionally, anti-static and antibacterial treatments are important steps to enhance the fine of the jersey, contributing to a better wearing revel in for athletes.

The stitching system is fundamental to making sure the jersey’s neat look and structural integrity. In present day jersey production, pc-aided design and reducing generation (CAD) and automated stitching machines are extensively used to ensure precise cutting and excessive-velocity stitching performance. 3-dimensional slicing techniques make the jersey’s fit greater frame-conforming, presenting better athletic adaptability. special sewing strategies, including linings and binding, are used for precise regions like sleeve cuffs and collars to growth durability and aesthetics.

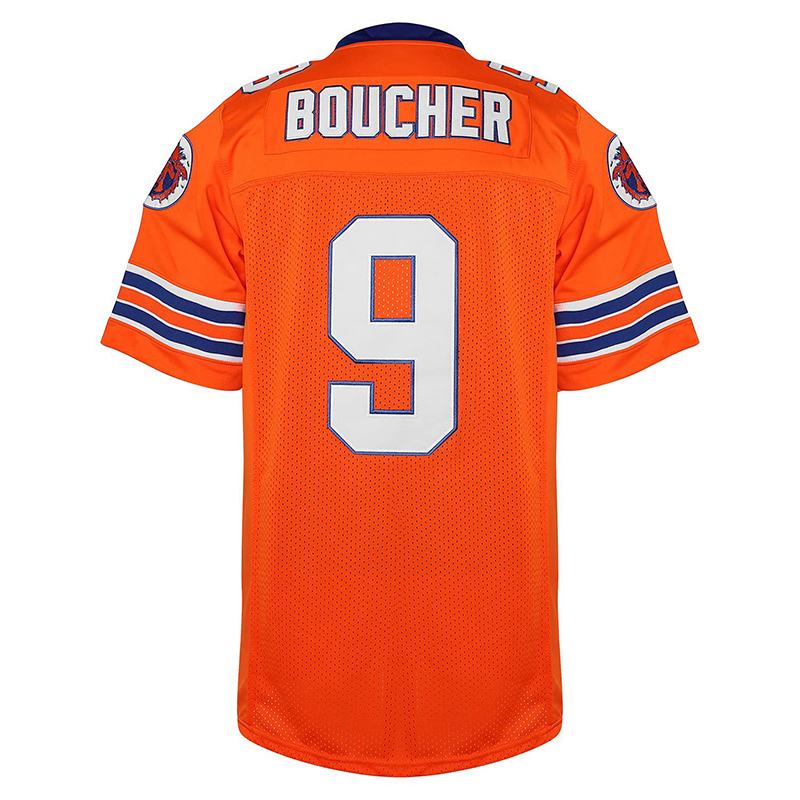

Detailing is likewise crucial for the jersey’s labels, numbers, and group trademarks, which can be both heat-sealed or embroidered. heat-sealing or embroidery ensures clean patterns that aren’t without difficulty, withstand lengthy-term washing and wearing. furthermore, for expert-degree jerseys, special materials which includes metallic or thermoplastic are often used for his or her sturdiness and professionalism.

With the development of era, the concept of smart jerseys is likewise emerging. those jerseys contain high-tech factors consisting of sensors and conductive fibers to monitor physiological information of athletes, which includes heart rate and frame temperature, offering extra personalised schooling and competitive help. In phrases of materials, smart jerseys typically use conductive materials like silver fiber to enable information transmission.

the usage of substances is likewise increasingly more essential. The concept of sustainable development encourages producers to discover the use of recyclable materials and biodegradable substances to reduce environmental impact. these materials preserve performance while additionally meeting contemporary clients’ call for for inexperienced and environmentally friendly products.

In precis, from material choice to processing techniques, to stitching era and detailing, substances and era collectively form the important thing to ensuring the first-class of sports jerseys. As era keeps to strengthen, the future of jersey production will vicinity greater emphasis on comfort, functionality, and environmental sustainability.

Market demand and trends: Insight into industry dynamics

inside the sports activities marketplace, jerseys, as iconic equipment for athletes, carefully follow market needs and trends in phrases of design, materials, and functionality. right here are a few key factors:

using performance fabrics is turning into greater large, with excessive-tech fibers which includes polyester, nylon, and spandex being employed. those materials now not only offer super breathability and moisture-wicking homes however also beautify the durability and stretch resistance of jerseys. With technological advancements, a few manufacturers are introducing smart fabric that comprise antibacterial retailers, UV safety, or temperature-manage functions to fulfill the diverse needs of expert athletes.

The fusion of fashion and sports activities has come to be a new fashion, as sports brands no longer attention totally on capability in jersey design however integrate style factors. Designers are using formidable colours, geometric styles, and unique cuts to draw younger purchasers. restricted version and collaboration jerseys are also in excessive demand, often proposing particular styles and tales, symbolizing the fashion trend.

Environmental awareness is developing, and using sustainable substances in jersey production is increasingly not unusual. substances including recycled plastics, biodegradable fibers, and organic cotton are getting used not best to reduce production fees however also to beautify the emblem’s environmental photograph. As customer reputation of merchandise increases, the industry is driving a shift in the direction of inexperienced transformation.

useful needs are diversifying, as sports maintain to grow to be more specialized, jersey designs for specific sports activities also are turning into extra customized. as an example, jerseys for sports like football, basketball, and tennis want to keep in mind the variety of movement, the scope of motion, and climatic conditions. details including concealed wallet, adjustable cuffs, and reflective strips are designed to decorate the sports activities revel in and protection.

The fashion in the direction of intelligence is clear, with a few high-stop jerseys now offering smart capabilities inclusive of heart rate monitoring, GPS monitoring, and records analysis. those features help athletes understand their performance in real-time all through training and competitions, providing coaches and athletes with greater medical education steerage.

market segmentation has turn out to be the norm, as purchaser demands diversify, the sports activities jersey marketplace has visible the emergence of segmented markets for specific demographics and sports. these consist of markets for professional athletes, amateur fanatics, and adolescents markets, amongst others. these segmented markets drive product innovation and marketplace growth.

brand opposition is intensifying, as extra manufacturers enter the sports activities jersey marketplace, opposition is becoming increasingly more fierce. The competition among brands is not restrained to rate but extends to product innovation, brand photograph, and customer support. through constantly launching new merchandise and improving provider great, brands are searching for to advantage a competitive area in the extreme marketplace opposition.

Quality Control and Certification: Establishing Industry Standards

inside the production process, pleasant manage is the middle link to make sure the great of sports crew jerseys. A stringent satisfactory control machine no longer best worries the product itself but also pertains to the brand photograph and patron accept as true with. under is an in depth description of satisfactory manage and certification:

-

design evaluation: at the design degree, expert design teams will carefully plan the jersey styles, colorings, and fits based at the characteristics of the sports activities challenge, climatic conditions, and the wishes of athletes. The design overview section aims to make certain that every jersey meets both practical and aesthetic requirements.

-

material selection: The fabric is the muse of the jersey, at once affecting the carrying comfort and sturdiness. The great control group will rigorously display diverse fabric, inclusive of polyester, polyester fiber, and nylon, and test their abrasion resistance, breathability, and moisture-wicking skills to make certain that the chosen fabric meets industry requirements and patron necessities.

-

sewing system: stitching is a essential level in jersey production, affecting the durability and look of the product. fine manage personnel will check the uniformity and firmness of the stitching strains, in addition to for any problems consisting of skipped stitches or fraying. additionally, for unique areas like collars and cuffs, more nice tests are carried out.

four. functional trying out: sports activities jerseys need to have sure functionalities, which includes warmth, breathability, and wind resistance. The best control group will behavior a series of functional assessments at the completed products, together with water stress resistance checks, breathability checks, and anti-ultraviolet assessments, to ensure that the jerseys carry out as expected all through real sports sports.

five. safety standards: sports jerseys have to also meet relevant protection standards, consisting of warding off accidents from sharp items and ensuring easy operation of zippers. exceptional manipulate personnel will conduct strict tests on the protection performance of the goods in line with worldwide and domestic rules.

-

Packaging and Labeling: inside the product packaging stage, the nice control team will check the great of the packaging materials, the firmness of the packaging, and make certain that the product labeling is clear and correct. proper packaging no longer simplest protects the product however also complements the emblem image.

-

Certification and checking out: to set up industry standards, many sports jersey producers choose to undergo testing by way of international authoritative certification our bodies. those certifications encompass ISO 9001 satisfactory control gadget Certification, all right-Tex standard one hundred Environmental Certification, and others. by passing these certifications, companies can exhibit that their merchandise meet worldwide standards in phrases of exceptional, environmental safety, and social duty.

-

client remarks: nice control is not static; customer feedback is an vital foundation for non-stop product optimization. establishments will acquire client usage comments, analyze the troubles, and as a result alter the production technique and product layout to ensure that every jersey meets market call for.

thru those procedures, sports jersey manufacturers can make sure that each product meets or exceeds industry requirements, therefore status out inside the fierce market competition and winning purchaser agree with.

Case Study: A Paragon of Successful Sports Jersey Manufacturers

in the design phase, a hit sports activities jersey producers emphasize near collaboration with sports brands, gaining a deep knowledge in their logo photo and product positioning. Designers paintings with logo traits, incorporating fashion factors to ensure every jersey has a completely unique design fashion and brand recognition.

in terms of fabric choice, those manufacturers goal for jersey fabric, the usage of breathable artificial fibers and natural cotton-linen blends to make certain comfort even as wearing. on the equal time, they use dyes to make sure vibrant and lasting shades at the same time as minimizing environmental pollutants.

In terms of reducing processes, manufacturers utilize advanced slicing system and era to ensure the jerseys healthy properly, providing desirable comfort and help to the wearer in each motion and at rest. furthermore, meticulous stitching strategies are employed, the use of expert stitching machines and thread to save you fraying and expand the lifespan of the jerseys.

pleasant manage is paramount during the manufacturing method. manufacturers have hooked up rigorous fine control structures, with dedicated best inspectors overseeing every system from uncooked cloth inspection to very last product exams. Any substandard merchandise are at once rectified or discarded to ensure every jersey meets requirements.

To in addition set up industry standards, a success manufacturers actively seek numerous certifications. They reap ISO exceptional management gadget certifications to make sure the manufacturing method meets global standards. additionally they collect certifications like all right-Tex preferred 100, proving the goods are innocent to human beings and the environment.

Taking a sports logo as an example, its jersey producer not only focuses on technological innovation however also maintains abreast of marketplace traits. It designs jerseys that adapt to the specific characteristics of various sports such as basketball, soccer, and music and area. additionally, it introduces jerseys with functional variations ideal to different climates, which include short-dry and thermal kinds.

In phrases of advertising, producers participate in home and worldwide sports activities equipment alternate suggests to exhibit their product abilities and make bigger income channels. additionally they collaborate with primary sports activities activities, imparting reputable healthy jerseys to enhance emblem popularity and marketplace share.

For after-income carrier, manufacturers have established a complete after-income device to offer fast responses and guide. They promptly cope with consumer remarks to ensure client delight.

through these measures, a hit sports jersey producers have set a precedent in the industry, making a fine contribution to the improvement of the entire sports clothing manufacturing region.

Sustainable Development: Corporate Social Responsibility and Environmental Measures

inside the manner of manufacturing sports jerseys, the philosophy of sustainable development is deeply integrated, which no longer simplest reflects the enterprise’s social responsibility however also highlights the importance of environmental safety. here are some specific measures taken in the realm of sustainability:

- Adoption of fabric: modern-day sports jersey producers tend to apply sustainable materials in material choice, including natural cotton, recycled polyester, and bamboo fiber, among others. those materials no longer best reduce the environmental burden but additionally provide a relaxed carrying enjoy.

- electricity efficiency improvement: Factories adopt electricity-saving gadget and technologies, which includes LED lighting, excessive-performance heating and cooling structures, and the usage of renewable strength sources like sun and wind strength, to lessen electricity intake.

- Water aid control: during manufacturing and cleansing approaches, jersey producers have carried out strict water resource management measures, such as recycling and purification, to reduce water consumption and pollutants.

- Waste recycling and utilization: by setting up a waste fabric recycling gadget, consisting of the reuse of cut-off edges, and the recycling of packaging substances, corporations reduce waste technology and environmental harm.

- lifestyles cycle evaluation of merchandise: From the acquisition of uncooked materials to the disposal of the very last product, sports activities jersey producers behavior environmental assessments of the entire lifecycle to ensure the minimization of environmental impact.

- employee training and recognition enhancement: by way of training personnel on know-how and competencies related to sustainable improvement, companies can growth employees’ consciousness of environmental measures and inspire them to take action of their day by day paintings.

- client training: with the aid of speaking with purchasers approximately the sustainable capabilities of the jerseys, and inspiring them to recollect environmental elements whilst making purchases, the enterprise’s sustainable improvement is promoted.

- community involvement: with the aid of interacting with neighborhood communities, sports jersey manufacturers participate in social tasks including tree planting and environmental education, to beautify emblem picture and sell the green development of the community.

these measures not only assist businesses lessen their environmental footprint however also advantage customer desire and beautify brand photograph. at the course of sustainable development, sports jersey producers are continuously exploring and innovating, laying a solid basis for the future improvement of the industry.