Sports Jersey Customization Trends, Market Segmentation, and Sustainability Strategies in Spanish with IT and Q Analysis

In the sports market, athletic jerseys serve as a representation of athletes’ images and have always been a focus for both brands and consumers. With the increasing diversification of market demands, jersey customization services have emerged, and at the same time, how to achieve sustainable development in the jersey industry has become a significant issue. This article will delve into the development trends of jersey customization services, market segmentation, and strategies for industry sustainability.

Overview of Shirt Production

in the realm of sports, the jersey is not only a provider of individuality for athletes however additionally a image of team spirit. The production of jerseys is a complex and meticulous technique, concerning severa steps from design to finished product. here is a quick overview of the jersey production procedure.

The design phase is the starting point for jersey production, where designers create unique jersey patterns based totally on purchaser necessities, the traits of the game, and the brand’s picture. This system requires designers to have a robust foundation in artwork and a wealthy understanding of sports culture to make sure that the design is each aesthetic and realistic.

material choice is a vital step in jersey production, with fabric being the premise for making sure the performance and luxury of the jersey. commonplace jersey materials consist of polyester, nylon, and polyester fibers, which give excellent breathability, moisture-wicking, and put on resistance. for the duration of manufacturing, substances with unique functions together with fireplace resistance, waterproofing, and warmth are chosen primarily based on the wishes of various sports.

reducing is the second major step in jersey manufacturing, figuring out the jersey’s fit and length. superior reducing system ensures the precision of every piece of cloth, lowering waste. moreover, cutters need to use ergonomic ideas to ensure the jersey suits conveniently when worn.

stitching is the most delicate part of jersey production and the important thing to first-class. skilled seamstresses use expert stitching machines to stitch the pieces of cloth collectively according to the layout drawings. at some point of the stitching procedure, attention must be paid to the coping with of thread ends, the evenness of the sewing, and the power of the seams to ensure the durability of the jersey.

Printing and embossing techniques also are integral in jersey production. using excessive-temperature and high-pressure system, team trademarks, names, and numbers are accurately published or embossed onto the jersey. This step calls for clean, vibrant, and fade-resistant printing styles.

exceptional inspection is the final checkpoint to make certain product nice. at the manufacturing line, expert quality inspectors test each jersey in my view to make certain there are not any troubles consisting of tears, uncovered thread ends, or inconsistent hues. additionally, the size, weight, and breathability of the jerseys are examined to ensure they meet country wide standards.

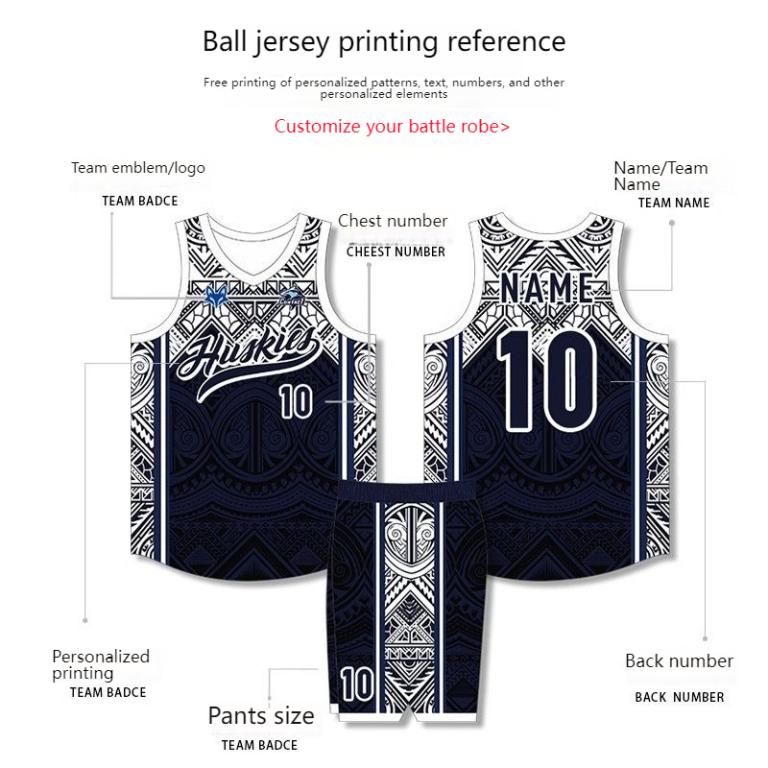

With the diversification of market demand, jersey production is also moving toward customization. Many producers provide personalized jersey customization offerings, together with team emblem customization, participant wide variety customization, and jersey pattern customization, to fulfill the desires of various customers.

within the context of sustainable development, jersey production is also exploring environmentally pleasant substances and technology. This consists of using biodegradable fabric and water-saving and energy-saving dyeing processes to reduce environmental impact.

Jersey production is a complex technique that encompasses various levels which includes design, fabric choice, reducing, sewing, printing, and inspection. every jersey is the result of the designer’s creativity, the people’ hard paintings, and technological innovation.

Key Points for Designing Sports Jerseys

-

style and sample: The layout of the jersey need to align with the characteristics of the sport it is meant for. for example, basketball jerseys usually feature a loose cut for ease of movement, while soccer jerseys often have a decent healthy to decorate consolation for the duration of play. pattern layout must encompass critical factors which includes the emblem logo, sponsor logos, and symbolic patterns of the sport, whilst additionally that specialize in coloration coordination and visible impact.

-

cloth choice: the choice of material for sports jerseys directly influences the carrying revel in and performance. fabric need to have right breathability, moisture-wicking homes, and wrinkle resistance. common fabric consist of polyester, spandex, and cotton, with appropriate cloth mixtures selected primarily based on distinct sports activities requirements.

three. consolation: The design of the jersey need to recollect ergonomics to make certain there’s no throughout movement. info which includes the collar, cuffs, and hem should be nicely-designed to avoid friction and pain.

- protection: when designing sports activities jerseys, safety concerns should be taken under consideration. for example, soccer jerseys ought to have clear numbers and names for easy identification by means of referees and spectators; basketball jerseys ought to have numbers and names in a area that enables communication and coordination amongst teammates.

five. Personalization: to satisfy the desires of various athletes and groups, jersey layout lets in for personalisation, along with choosing precise colorings, including special patterns, and customizing numbers and names.

-

practical layout: With the advancement of technology, practical layout in sports jerseys is increasingly valued. This consists of incorporating fabrics with special capabilities inclusive of antibacterial, smell-resistant, and sun-protection to enhance the overall overall performance of the jersey.

-

sturdiness: As sports activities jerseys are prone to put on and tear, sturdiness ought to be considered in the layout. selecting durable fabric and reinforcing sewing can enlarge the lifespan of the jersey.

eight. Environmental responsibility: current jersey layout is increasingly focusing on environmental worries, with using biodegradable and fabrics to limit environmental effect.

-

Adaptability to unique Climates: relying on distinctive climate situations, jersey layout can comprise greater breathable fabric or upload thermal layers to ensure athletes have a comfy wearing experience in diverse weather conditions.

-

style factors: As traits alternate, sports activities jersey layout is incorporating more style elements, along with coloration blockading, patchwork, and prints, making the jerseys more customized and fashionable.

Material Selection and Quality Standards

the manufacturing of sports jerseys is based heavily on the choice of substances and satisfactory standards to make sure product performance and durability. the subsequent is a detailed description of this degree:

colorful jerseys are the end result of a strict selection procedure for fiber materials. the choice criteria mainly consist of the subsequent factors:

-

Cotton Fiber: historically, sports activities jerseys regularly use cotton materials because of their properly breathability, moisture absorption, and luxury. however, cotton jerseys are vulnerable to wrinkles and have poor washability. In cutting-edge jersey manufacturing, cotton substances are frequently mixed with different fibers to enhance their performance.

-

Polyester Fiber: Polyester fiber is the mainstream material in jersey manufacturing, acknowledged for its amazing abrasion resistance, wrinkle resistance, and easy cleansing. the usage of high-density polyester fiber can beautify the durability and tear resistance of the jersey.

-

Spandex Fiber: Spandex fiber has proper elasticity, that may improve the fit and wrapping sense of the jersey, making it greater at ease for athletes to transport. however, spandex fiber is more expensive, so it needs to be used moderately in manufacturing.

four. Water-primarily based Dyes: To make sure the environmental friendliness of the jerseys, the use of water-based dyes is a ought to. compared to traditional dyes, water-based dyes are environmentally friendly, provide even dyeing, and aren’t prone to fading.

based totally on fabric selection, best standards are similarly critical:

-

Fiber first-class: The period, fineness, and strength of the fibers need to meet countrywide or industry standards. as an example, the tensile energy of polyester fiber need to not be much less than 2.five MPa.

-

material performance: The material have to have true tensile, resilience, and breathability. as an instance, the jersey’s tensile performance ought to reach over 50%, and its resilience have to attain over 80%.

-

coloration Fastness: The color fastness of the jersey is an vital indicator of product first-class. This includes wash fastness, rub fastness, and have to all attain degree four or above.

four. stitching method: The sewing of the jersey must be unique, without a skipped or overlooked stitches on the seams. The thread colour ought to match the jersey coloration to make certain aesthetics.

- safety requirements: The manufacturing of jerseys need to comply with relevant safety standards, including the prohibition of harmful materials and ergonomic design.

The cloth choice and excellent standards for sports activities jerseys at once effect the overall performance of the product and the customer’s experience of use. Strictly controlling every level of the production technique to make certain product high-quality is the key to the sustainable improvement of jersey production corporations.

Process Flow Analysis

The detailed description of the process of producing sports team jerseys, with an analysis of the manufacturing process, is as follows:

-

Fabric CuttingThe first step in producing team jerseys is to select the appropriate fabric. Common fabrics used for sports jerseys include polyester, nylon, and cotton, chosen based on the type of sport and climatic conditions. The cutting phase requires precision to ensure that each piece’s dimensions and shapes match the design drawings. The edges of the cut fabric must be trimmed to avoid any frayed edges affecting subsequent processing.

-

Sewing TechniqueSewing is the core part of jersey production. Modern jersey sewing techniques include flat stitching, enclosed stitching, and hemming, among others. Flat stitching is used to connect pieces, enclosed stitching to protect edges and prevent fraying, and hemming to reinforce the seam strength. During the sewing process, the speed, pressure, and stitch density of the machine must be strictly controlled to ensure even and sturdy stitching.

-

Compression and ShapingAfter sewing, jerseys need to be compressed and shaped. This step helps to remove any stresses that the fabric may have developed during production, making the jersey more flat. Additionally, through high temperature and pressure, the stitching can be fixed, improving the jersey’s washability and lifespan.

-

Printing and EmbroideryThe team emblem, numbers, sponsor logos, and other elements on the jerseys are completed through printing or embroidery techniques. Printing includes screen printing and heat transfer, while embroidery is categorized into flat embroidery and three-dimensional embroidery. These processes require the selection of suitable colors and materials based on design requirements to ensure that the patterns are clear and colors are vibrant.

-

Quality InspectionQuality inspection is an indispensable part of the jersey production process. The inspection includes fabric quality, stitching quality, and printing quality, among others. Inspection is conducted through visual checks and instrumental testing to ensure that each jersey meets quality standards.

-

Packaging and DispatchAfter passing the inspection, jerseys enter the packaging phase. The packaging materials must be environmentally friendly and have certain moisture-proof and dust-proof functions. After packaging, jerseys are sorted, boxed, and prepared for dispatch. Before dispatch, the boxes are sealed to ensure safety during transportation.

-

Post-ProcessingFor jerseys with special requirements such as waterproof, breathable, and antibacterial properties, additional chemical treatments are required. These treatments are carried out on professional equipment to ensure that the additional functions of the jerseys meet expectations.

The analysis of the entire production process aims to ensure that each sports jersey meets consumer and market demands in terms of quality, performance, and appearance. From fabric selection to finished product dispatch, every step reflects a focus on detail and pursuit of quality.

Market trends and consumer demands

The market trends for sports apparel are continuously evolving with the development of the times, and consumer demands are becoming increasingly segmented. Here is a brief description of this field:

Integration of Fashion Elements: In modern sports apparel design, the fusion of fashion elements with performance has become a major trend. Designers no longer solely focus on functionality but also pay attention to how to combine trendy colors, patterns, and sports apparel to meet consumers’ pursuit of personalization and fashion.

Balancing Functionality and Comfort: With the advancement of technology, the functionality of sports apparel has significantly improved. Features such as breathability, moisture-wicking, and antibacterial odor control have become key criteria for assessing the quality of a sports jersey. While consumers seek fashion, they also value the comfort provided by the clothing.

Rise of Customization Services: Driven by personalized consumption, the customization services for sports apparel are increasingly popular. Consumers can customize colors, patterns, sizes, and more according to their preferences, making the sports apparel market more diverse.

Differentiated Competition Among Sports Brands: In the fierce market competition, sports brands are meeting different consumer needs by launching products with different positioning. High-end brands focus on quality and innovation, mid-range brands seek to break through on cost-performance, and emerging brands attract young consumers through unique design philosophies and marketing strategies.

Increased Environmental Awareness: With the rise of environmental awareness, consumers are increasingly demanding environmental performance from sports apparel. Green production, biodegradable materials, and the reduction of chemical substances are focuses for sports brands. The demand for environmentally friendly sports apparel is growing.

Deepening Health Lifestyle Concept: The popularity of a healthy lifestyle has increased consumer demand for sports, thereby driving the development of the sports apparel market. Consumers pay more attention to the health and safety performance of products when choosing jerseys.

Integration of Online and Offline Channels: With the rapid development of e-commerce, the sales channels for sports apparel have changed. The convenience of online channels allows consumers to easily purchase their desired products, while offline stores provide a more direct experience and fitting services. The trend of online and offline integration is becoming more apparent.

Sports Events Drive Demand: Large-scale sports events, such as the World Cup and the Olympics, have a significant impact on the sports apparel market. During these events, major brands release limited edition jerseys to attract fans and boost sales.

In summary, the trends in the sports apparel market and consumer demands show characteristics of diversification, personalization, functionality, and environmental friendliness. Brands need to keep pace with market trends and innovate continuously to meet the diverse needs of consumers.

Customized Jersey Service and Market Segmentation

The customization service for sports jerseys is increasingly becoming a new favorite in the market, closely tied to market segmentation. Here is a detailed description of this field:

The personalized design of custom jerseys satisfies consumers’ pursuit of uniqueness. With the advancement of technology, consumers can participate in the design of jerseys through various channels, from choosing colors and patterns to adding personalized signatures, with every detail adjustable according to individual preferences.

In terms of market segmentation, the jersey customization service primarily targets the following groups:

-

Professional sports teams: Including various levels of football clubs, basketball teams, soccer teams, etc., who require customized jerseys to reflect their team’s characteristics and sponsor brands.

-

Club members and fans: Many clubs offer exclusive customized jerseys to members to enhance a sense of belonging and loyalty among fans.

-

Businesses and individuals: Businesses use customized jerseys as employee uniforms or event attire to boost their corporate image, while individuals may order them for special events or to commemorate specific sports events.

-

Campus sports activities: School sports clubs or teams may customize jerseys to strengthen team cohesion and campus culture.

While satisfying diverse needs, the customization service also exhibits the following characteristics:

-

Diverse fabric options: From breathable polyester to warm wool blends, the choice of fabric directly affects the comfort and durability of the jersey.

-

Rich pattern design: Combining various techniques such as embroidery, printing, and heat transfer, pattern designs can be very intricate, even including complex team crests, sponsor logos, and more.

-

Custom sizing: Providing precise measurement and adjustment services for sizes ensures that jerseys fit well and enhance athletic performance.

-

Rich accessories: In addition to the jerseys themselves, this may include items such as shorts, socks, scarves, and other matching products to meet the overall styling needs of consumers.

-

Quality assurance: Customization services emphasize quality, with strict quality inspections from raw materials to finished products, ensuring the durability and safety of the jerseys.

As consumer demand for personalization continues to grow, the market for jersey customization services is expanding. With technological progress and the increased awareness of consumers, this field is expected to see more innovation and development in the future.

Sustainable Development Strategies for the Jersey Industry

In the process of jersey production, the application of environmentally friendly materials has gained increasing importance. The use of recyclable and biodegradable fibers such as polylactic acid (PLA) and biobased polyesters helps reduce environmental impact. Simultaneously, promoting recycling policies and encouraging consumers to recycle old jerseys supports the reuse of resources.

Reducing energy consumption and carbon emissions during the production process is also crucial. By introducing energy-saving equipment and technologies such as LED lighting and high-efficiency motors, significant reductions in energy consumption during production can be achieved. Additionally, optimizing production line layouts to reduce material transport distances can also contribute to lowering energy use.

The management of water resources in the production phase is equally important. The adoption of water-saving equipment and technologies such as closed-loop water systems and high-efficiency filtration systems can effectively reduce water waste. At the same time, the treatment of wastewater ensures compliance with emission standards, protecting water resources.

In the packaging phase of jerseys, reducing the use of single-use plastics and switching to environmentally friendly materials like biodegradable plastics and paper packaging is a significant step towards sustainable development. Moreover, optimizing packaging design to reduce volume and weight can also help lower transportation costs and carbon emissions.

In marketing, jersey brands should actively promote green consumption ideas, attracting consumer attention through the environmentally friendly production process and product features. Additionally, conducting environmental protection public welfare activities can enhance brand image and strengthen consumer identification with the brand.

In supply chain management, the jersey industry needs to strengthen cooperation with upstream suppliers to drive the green transformation of the entire industrial chain. By establishing an environmental assessment system, suppliers can be screened and supervised to ensure the green sustainability of the supply chain.

At the end of the product lifecycle, jersey brands should encourage consumers to participate in recycling to achieve the circular utilization of products. By establishing a recycling network, the collected jerseys can be categorized and processed to extract recyclable materials, reducing the environmental impact.

The jersey industry should also focus on technological innovation, developing new environmentally friendly materials, improving production efficiency, and lowering costs. By continuously optimizing production processes, enhancing resource utilization rates, and increasing product added value, a win-win situation of economic and environmental benefits can be achieved.

The sustainable development strategies of the jersey industry include: promoting environmentally friendly materials, optimizing production processes, conserving energy and water resources, reducing packaging waste, advocating for green consumption, strengthening supply chain management, promoting product circular utilization, and technological innovation. Through these measures, the jersey industry will better integrate into the green economic system and contribute to the protection of the Earth’s environment.