Sports Jersey Case Study: A Deep Dive into Quality, Technology, and Market Responsiveness

With the fast development of the sports enterprise, the marketplace for sports activities jerseys has shown a trend of diversification and personalization. this newsletter will delve into the production method of sports jerseys, inclusive of material selection, craft production, first-class control, and marketplace trends, aiming to offer readers with a comprehensive deep dive into the sports jersey industry.

Case Study Overview

The sportswear device industry, with the jersey as one in every of its center merchandise, locations splendid emphasis on the production procedure and first-rate control. this article takes a renowned jersey manufacturing facility as an example to delve into its production process, cloth selection, fine control, and marketplace reaction.

The manufacturing facility is placed in an economically advanced region in southern China, geared up with present day production lines and a strict great management system. It basically produces reliable jerseys for various recreation brands, along with football, basketball, and volleyball. the following is an outline of the manufacturing unit’s jersey manufacturing case.

The factory operates on an order-based manufacturing model, customizing production in line with client orders. The production cycle generally degrees from 15 to 30 days, relying at the complexity and amount of the order. Upon receiving an order, the manufacturing facility speedy proceeds with raw fabric procurement and manufacturing making plans.

In terms of raw material procurement, the manufacturing unit strictly controls dealer qualifications to make certain that every one substances meet international environmental requirements. the principle materials consist of polyester, spandex, and cotton, which all show off true performance in phrases of sturdiness, breathability, and comfort. The factory has long-standing cooperative relationships with several domestic and worldwide material corporations to make sure material first-class and supply balance.

In terms of production generation, the manufacturing unit has brought internationally advanced system and generation, together with pc embroidery, warmness transfer, and digital printing. these methods make sure that the jersey patterns are clear, colors are vibrant, and are proof against fading. moreover, the factory pays specific attention to jersey fit layout, ensuring consolation and suitability for athletes of different body types.

first-class manipulate is the pinnacle precedence in the manufacturing facility’s manufacturing. multiple great manage checkpoints are installation all through the production manner, from uncooked cloth inspection to completed product dispatch. The excellent manage branch conducts random inspections at each degree to make certain that the goods meet relevant requirements and patron requirements. For non-compliant objects, the manufacturing unit takes instant corrective moves to make sure the very last product exceptional.

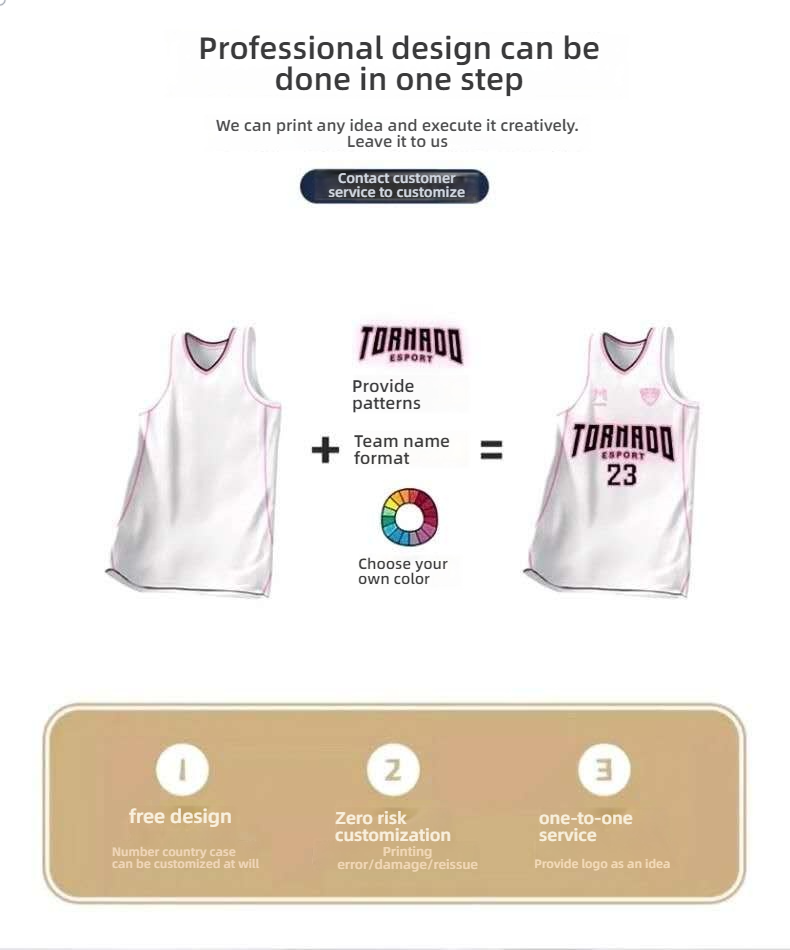

In reaction to the ever-converting marketplace needs and emblem positioning, the manufacturing unit continually adjusts its manufacturing techniques. In latest years, with the upward thrust in consumer demand for personalisation and personalization, the factory has released numerous personalized offerings, along with customized participant signed jerseys and crew emblem customization. these offerings now not only meet the diverse market needs however additionally add value to the brand.

it is glaring that the jersey manufacturing unit demonstrates a high degree of professionalism in manufacturing control, best manipulate, and market responsiveness. via the great management of the production method, the manufacturing facility can efficaciously and high-qualityly meet customer needs and preserve a aggressive edge in the extreme marketplace competition. The case suggests that within the sports system industry, refined control and non-stop innovation are important riding forces for organization development.

Process Flow Analysis

-

Fabric Preparation: The production of sports team jerseys begins with the selection of the appropriate fabric material, depending on the requirements of different sports, such as breathability, wear resistance, and elasticity. The fabric undergoes preliminary processing such as cutting,, and pressing to ensure smooth progress in subsequent operations.

-

Pattern Design: The design team creates jersey patterns based on customer requirements and the characteristics of the sport. Once the pattern design is complete, it is converted into a producible electronic file using digital technology, preparing it for printing.

-

Printing Process: The jersey patterns are printed using processes such as screen printing, heat transfer, and pad printing. During the printing process, it is necessary to control the uniformity of the inks, drying time, and temperature to ensure the clarity of the pattern and the vibrancy of the colors.

-

Cutting and Assembly: After printing, the fabric is cut to the required design dimensions and then assembled according to the style requirements. During assembly, it is essential to ensure precise dimensions and neat stitching to maintain the jersey’s overall aesthetics and comfort.

-

Sewing Operations: Once cutting and assembly are complete, the jersey moves into the sewing phase. This includes stitching, hemming, and processes, which require even stitching, strong seams, and the absence of broken threads or skipped stitches.

-

Post-Processing: After sewing, the jerseys are post-processed, which includes ironing, folding, and packaging. This stage is intended to ensure the cleanliness of the jerseys and enhance product quality.

-

Quality Inspection: At each stage of production, strict quality inspection standards are in place. From fabric to finished product, multiple inspection procedures are conducted to ensure that the final product meets customer requirements.

-

Logistics Distribution: The inspected jerseys enter the logistics phase, where they are packed and shipped according to order specifications. During transportation, it is crucial to ensure the safety of the jerseys and prevent damage.

-

After-Sales Service: After product delivery, provide corresponding after-sales services, including jersey cleaning, maintenance, and repair. This helps to increase customer satisfaction and build a brand image.

-

Continuous Improvement: During production, continuously collect customer feedback and optimize the production process to improve efficiency, reduce costs, and enhance product quality.

Material Selection and Process

In the production of jerseys, the choice of materials and the rigor of the manufacturing process are crucial. Below is a detailed analysis of materials and processes involved in the manufacturing of jerseys:

The fabrics typically used for jerseys include polyester, cotton, and spandex, among synthetic fibers. Polyester is often chosen as the main fabric due to its high strength, wear resistance, and ease of cleaning. Cotton fabrics offer good breathability and comfort, making them suitable for wearing during exercise. Spandex, with its elasticity, is used to enhance the stretchability of jerseys, thereby improving comfort during wear.

In terms of sewing techniques, precise cutting is essential to ensure a good fit. High-precision cutting equipment is used to ensure that each piece of fabric perfectly conforms to the human body curves. During the process, professional sewing machines are employed to ensure even and sturdy stitching. For critical areas such as necklines and cuffs, double or multiple stitching is used to increase durability.

The of jerseys requires meticulous attention, especially for parts with patterns or special designs. Heat transfer or screen printing techniques are used to ensure clear and lasting patterns. Heat transfer requires strict control of temperature and pressure to prevent pattern deformation or fading. Screen printing must also pay attention to the quality of inks and the uniformity of printing.

In terms of the internal structure of jerseys, functional design is emphasized. For example, moisture-wicking materials such as polyester are added to the back of the jersey to enhance dryness and comfort during exercise. Additionally, to reduce friction, the lining of the jersey often uses soft cotton or polyester materials.

The zipper treatment is a key aspect of the manufacturing process. Durable and easy-to-operate zippers are chosen, with reinforcement at the zipper head and teeth for smooth use during exercise. The feel of the zipper when closing and opening is also a consideration.

In terms of edge treatment, the jersey typically uses binding, using colors similar to the main fabric to maintain a unified and aesthetic appearance. The choice of binding thread needs to consider strength and appearance to prevent the edges from unraveling.

The washing and care labels on jerseys must be clear and easy to understand, indicating the correct methods of washing and caring for the jersey to ensure long-term effectiveness. The labels must be both aesthetically pleasing and durable, not easily falling off.

Quality Control and Standards

In the production process, the quality control and standards for soccer jerseys are crucial for ensuring the product meets expected performance and customer satisfaction. The following is a detailed description of this critical phase:

Rigorous Raw Material Selection: To ensure the quality of the soccer jerseys, the factory conducts strict quality inspections on materials such as fabrics, dyes, and embroidery threads. Fabrics must meet performance requirements such as abrasion resistance, breathability, and moisture wicking, while dyes must pass environmental certifications to avoid harmful substance residues.

Standardized Sewing Techniques: During the production process, the factory follows unified process standards. Every step from cutting, sewing, ironing to finished product packaging is governed by strict operational specifications to ensure that stitching is neat, seams are even, and the appearance is aesthetically pleasing.

Finished Product Inspection: Before the finished soccer jerseys are dispatched, they undergo multiple inspection procedures. Inspections include dimensions, fit, color, clarity of patterns, and the stability of seams. Non-conforming garments are returned to the production line for rework.

Functional Testing: For functional soccer jerseys, such as those designed for sports or thermal protection, the factory conducts professional functional tests. This includes assessing the moisture-wicking ability, breathability, and thermal insulation of the jerseys to ensure they meet specific athletic requirements.

Compliance with Environmental Standards: The factory strictly adheres to national environmental standards during production, ensuring the harmless treatment of wastewater, waste gases, and solid waste to minimize environmental impact.

Quality Traceability System: To facilitate product quality traceability, the factory has established an. Detailed records are kept for every stage from raw material procurement to finished product sales. In the event of quality issues, the factory can quickly identify the source and take appropriate measures.

Customer Feedback Collection: The factory values customer feedback and has a dedicated department to collect opinions and suggestions on the quality of the soccer jerseys. Based on customer feedback, the factory continuously optimizes production processes and improves product quality.

Professional Training and Assessment: The factory conducts regular professional training for employees to enhance their operational skills and quality awareness. Employees are also assessed to ensure that each can master the production process and quality control standards proficiently.

Through these quality control and standard measures, the soccer jersey factory ensures product quality and has earned the trust of the market and customers.

Market Trend and Demand Analysis

With the fast development of the sports enterprise, the market for sports activities jerseys is displaying various and personalized characteristics. right here is an analysis of the marketplace developments and needs:

clients’ demand for jerseys is not confined to functionality, as stylish elements are increasingly more being incorporated into them. more youthful generations of purchasers are more willing to pick out jerseys with unique designs and vibrant colorations to meet their personalised desires.

The utility of sports era is becoming a trend, with clever jerseys gaining attention. those jerseys provide functions including coronary heart price monitoring and GPS tracking, improving the sports activities enjoy and imparting athletes with greater records assist.

The concept of environmental safety is deeply rooted in human beings’s minds, and the use of sustainable materials in jersey production is growing. as an instance, jerseys made from recycled polyester and natural cotton are gaining an increasing number of popularity amongst customers.

opposition among sports manufacturers is becoming increasingly fierce, with move-border collaboration turning into the norm. Collaborations among sports manufacturers, style brands, and technology groups are making jersey designs more numerous and assembly the desires of various clients.

The upward push of esports has driven the demand for esports crew jerseys. Esports team jerseys now not simplest want to have proper performance but also want to have robust emblem persona and fan.

The demand for custom designed jerseys for expert sports activities activities is continuously developing. With the internationalization and professionalization of sports activities activities, the customization necessities for jerseys have become higher, such as design, fabric, and capability.

The kids and young people sports activities marketplace is heating up, and jersey designs for this marketplace are increasingly focusing on comfort and protection. mother and father’ requirements for children’s jerseys are moving from practicality to health and environmental friendliness, even as additionally taking note of emblem picture.

There are considerable local differences inside the jersey market. the ecu and American markets have higher necessities for the fashionability and functionality of jerseys, whilst the Asian marketplace places more emphasis on price-effectiveness and logo influence.

With the recognition of social media, the advertising methods for jerseys also are converting. manufacturers are the usage of social media systems to exhibit jersey designs, interact with purchasers, and enhance logo popularity and have an impact on.

In summary, the sports jersey marketplace is displaying traits of diversification, technologization, environmental safety, and personalization. manufacturers need to hold up with marketplace modifications and innovate constantly to meet the ever-evolving needs of purchasers.

Cost control and efficiency enhancement

Certainly, here is the translation of the provided content into English:

-

Raw Material Procurement Strategy: The factory establishes long-term stable partnerships to directly purchase raw materials from suppliers, reducing intermediate links and lowering procurement costs. Additionally, through bulk purchasing, they enjoy more favorable discounts, further compressing costs.

-

Production Process Optimization: The factory introduces lean production concepts in the production process, analyzing production rhythms, and optimizing production layouts to minimize unnecessary movement and waiting times. For example, by logically setting up material placement on production lines, the time workers spend on picking materials is reduced, improving production efficiency.

-

Application of Automated Equipment: The factory employs automated equipment in key processes, such as automatic cutting machines and high-speed sewing machines, which not only increase production speed but also reduce the rate of defective products due to human error.

-

Energy Management: The factory strictly monitors energy consumption, implementing energy-saving equipment, optimizing lighting systems, and adjusting equipment operating times to effectively reduce energy costs.

-

Inventory Management: Implementing an effective inventory management system, the factory monitors inventory levels in real-time, predicts market demand rationally, and avoids stockpiling and stockouts, thus reducing inventory costs.

-

Employee Training: Regularly train employees to improve their operational skills and efficiency. With higher-level skills, employees can complete work in less time, reducing labor costs.

-

Quality Management: Strengthen quality control to reduce rework and waste rates. Through strict inspection processes, ensure that every jersey meets quality standards, reducing additional costs due to quality issues.

-

Supply Chain Collaboration: Establish close collaborative relationships with suppliers and distributors, ensuring accurate execution of production plans through information sharing and rapid response, reducing cost increases due to supply chain issues.

-

Market Analysis: Continuously monitor market dynamics and adjust production plans according to market demand, avoiding cost fluctuations due to overproduction or underproduction.

Through these measures, the jersey factory manages to control costs while significantly enhancing production efficiency. This not only improves the competitiveness of the enterprise but also provides consumers with affordable and high-quality products.