Jersey Knit Fabric: The Ultimate Material for Comfortable Clothing, Sports Wear, and Beyond

in the sports activities garb industry, jerseys function the showcase for logo identification and athletes’. the selection of fabric in their manufacturing is essential. Jersey knit cloth, with its unique comfort and capability, has grow to be the preferred material for jersey manufacturing. this newsletter will delve into the characteristics, packages, and marketplace developments and possibilities of jersey knit material, and discuss the importance of exceptional manipulate and checking out standards.

Jersey Knit Fabric Introduction

Jersey knit cloth, additionally referred to as elastic knitted cloth, is a type of cloth with excessive elasticity and good breathability. it is synthetic through knitting techniques, wherein the yarn forms a decent mesh structure inside the material, making it smooth, comfy, and with high-quality stretch and healing properties.

the primary uncooked materials for this material are normally cotton, polyester, spandex, and different fibers. through distinctive mixing ratios, a ramification of styles and overall performance traits of jersey knit fabric can be produced. Its features include:

- extraordinary Elasticity: Jersey knit fabric boasts properly elasticity, which can adapt to the motion and form changes of the human frame, making sure consolation for the duration of wear.

- Breathability: The mesh shape allows air to drift freely in the cloth, offering notable breathability, particularly cozy to put on in warm weather.

- Wicking and Evaporation: some jersey knit fabric are dealt with to take in and evaporate sweat quick, retaining the pores and skin dry.

- smooth to Dye: The knitted structure makes the fabric smooth to dye, resulting in vibrant and sturdy shades.

Jersey knit fabric is extensively used inside the clothing enterprise, together with sports activities wear, informal wear,, and toddler apparel. In style design, it no longer handiest gives an excellent sporting enjoy but can also show off unique patterns and a experience of style thru special knitting techniques and sample designs.

The manufacturing process of jersey knit cloth commonly involves the following steps:

- uncooked fabric training: choose suitable fiber uncooked materials based totally on the desired fabric performance.

- Yarn practise: method the fiber raw substances into yarns and adjust the yarn thickness and twist in step with design requirements.three. Knitting system: Use knitting machinery to weave the yarns into jersey knit fabric.four. publish-treatment: carry out tactics along with dyeing, shaping, and softening on the material to enhance its excellent and usability.

As customers’ pursuit of consolation and fashion in garb maintains to grow, the call for for jersey knit material is on the upward thrust. destiny marketplace tendencies will focus extra on the environmental friendliness, capability, and personalized layout of fabrics. on the equal time, technological innovation will power jersey knit fabric toward better performance and extra various development. In phrases of pleasant manipulate, strict adherence to worldwide and national industry requirements is needed, with comprehensive inspections of uncooked substances, production approaches, and finished product fine to make sure the stable and dependable best of jersey knit cloth.

Jersey knit fabric characteristics and applications

Jersey knit fabric, additionally called elastic knit material, is a fairly elastic knitted cloth that is widely used in diverse fields which include clothing, domestic textiles, and healthcare. the following are its major characteristics and applications:

amazing Elasticity: Jersey knit material boasts excellent stretchability, imparting relaxed put on and the capacity to deal with numerous movements and postures of the human body.

precise Breathability: This fabric has right breathability, allowing the skin to remain dry even as wearing, making it suitable for all seasons.

Moisture-Wicking: Jersey knit cloth has right moisture-wicking houses, which can fast take in and evaporate sweat, decreasing the retention of sweat on the apparel.

smooth and comfy: The fabric is smooth and has a delicate texture, offering a at ease wearing enjoy to the wearer.

clean to Dye: Jersey knit fabric is easy to dye, with vibrant colors and wealthy styles, making it appropriate for generating various styles of apparel.

huge packages:

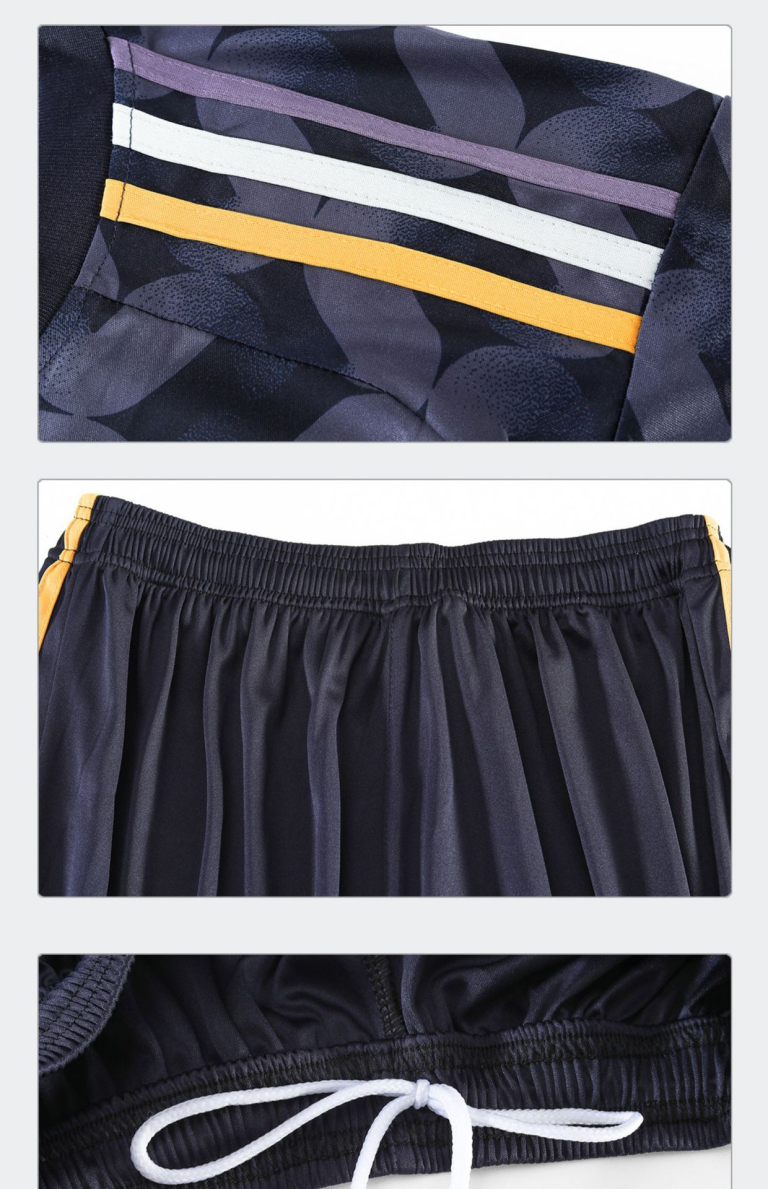

within the clothing industry: Jersey knit cloth is widely utilized in sports clothing, casual put on, undies, and different clothing products, such as T-shirts, sports wear, and domestic wear.

within the domestic textiles industry: Jersey knit material may be used to make bedding, towels, and bathrobes, providing a soft and relaxed contact.

in the healthcare industry: in the scientific field, jersey knit cloth can be used to make surgical robes, nurse uniforms, and so forth., imparting antibacterial, breathable, and relaxed features.

within the shoes industry: Jersey knit cloth can also be used to make insoles and upper parts of footwear, improving the comfort and breathability of the shoes.

within the toy industry: Jersey knit fabric also can be used to make various plush toys and filled animals, with shiny colours and gentle, lovable textures.

With the development of era, the application fields of jersey knit material are constantly expanding, and it’s far expected to play a sizeable position in even greater fields in the future.

Production Process Analysis

The method of producing jersey knit fabric entails more than one key steps, distinctive underneath:

uncooked material Processing: step one in generating jersey knit fabric is to manner the uncooked materials. usually, these are synthetic fibers like polyester or nylon, or herbal fibers together with cotton. The raw materials undergo cleaning, decontamination, and drying to ensure the best of the fibers for the following production.

Spinning: The cleaned fibers are then fed into spinning machines in which they’re twisted to shape continuous yarns. The spinning method impacts the final best of the material through figuring out the yarn’s thickness, twist, and electricity.

Knitting: The yarns are then knitted on knitting machines, which form the precise structure of jersey knit cloth. during the knitting manner, the yarns are interlaced at a sure density and sequence to supply different textures which include simple or pique.

finishing: The knitted material is then subjected to completing remedies to stabilize its length and form. this is generally completed via heat setting or mechanical stretching to make sure the material retains suitable elasticity and balance during washing and wearing.

Dyeing: The finished cloth enters the dyeing technique subsequent. depending on purchaser requirements, specific dyeing strategies which includes immersion dyeing, spray dyeing, or pad dyeing can be selected. The dyeing method calls for strict manage of temperature, time, and dye attention to make certain even color and colour fastness.

finishing: After dyeing, the cloth undergoes post-remedy, which includes procedures which include softening, anti-wrinkle remedy, and water-repellent treatment. those treatments decorate the cloth’s comfort, sturdiness, and functionality.

Inspection: first-class inspection of jersey knit fabric is crucial all through the production technique. Inspections include look assessments, dimensional measurements, power assessments, and colour fastness checks to make certain the product meets requirements.

Packaging: The inspected jersey knit material is then packaged for shipment. The packaging materials are generally dirt baggage, cardboard containers, or plasticboxes to guard the product for the duration of transportation.

Logistics: The packaged jersey knit material is sent to the patron via logistics channels. all through the logistics technique, it is essential to ensure the product isn’t always damaged and is added to the purchaser in a well timed way.

each level of the production process should be strictly controlled to ensure the first-class and performance of the jersey knit fabric meet marketplace needs.

Market Trend and Future Prospects Analysis

The market performance of jersey knit cloth has been increasingly prominent. the subsequent is an in-intensity analysis of its marketplace traits and potentialities:

cloth enhancements pressure call for growth, with high-give up jersey knit material turning into a brand new favored. As consumers’ pursuit of comfort and fashion in clothing keeps to upward push, jersey knit fabric, with its superb elasticity and softness, is desired, specifically inside the sports activities and entertainment sectors, wherein the market proportion of high-stop jersey knit cloth is continuously expanding.

Customization developments are obvious, with market segmentation diversifying. The growing call for for customization among clients has triggered the jersey knit material market to broaden in a greater diversified route. From shades and styles to blended materials, custom designed jersey knit fabric meets the particular tastes of different customers, riding marketplace segmentation and presenting manufacturers with a broader market space.

The concept of environmental safety is deeply rooted, and sustainable materials are gaining choose. With the worldwide upward push in environmental recognition, jersey knit material produced with environmentally pleasant materials is increasingly more attracting market attention. The utility of biodegradable fibers and recycled polyester no longer best reduces the environmental impact of products however also brings new market possibilities for companies.

Technological innovation drives enterprise upgrades, with intelligent manufacturing becoming a new path. With the development of technology, the manufacturing procedure of jersey knit fabric is constantly optimized. computerized and smart production device improves production efficiency, reduces fees, and also ensures the stableness of product quality. The sensible manufacturing version brings new momentum for the industry.

global market growth hurries up, with increased cross-border cooperation. The internationalization fashion of jersey knit cloth is clear, with an increasing number of chinese language companies collaborating inside the international marketplace. via foreign places investment, cooperative manufacturing facility creation, and different approach, establishments can not best develop their sales channels however additionally introduce advanced worldwide era and management experience to decorate their competitiveness.

policy guide is bolstered, and the development environment for the enterprise is optimized. The authorities’s coverage help for the textile enterprise continues to increase, including tax and charge reductions, business upgrade steerage, etc., presenting a positive improvement environment for the jersey knit cloth enterprise. at the equal time, the easing of worldwide trade frictions brings extra opportunities to the industry.

In summary, the marketplace prospects for jersey knit cloth are promising, but it additionally faces many challenges. enterprises want to preserve up with market trends, support technological studies and development, improve product nice, and pay attention to brand building to evolve to the ever-changing market demands.

Quality Control and Inspection Standards

inside the production manner of jersey knitted fabrics, nice manage is a critical. the following is a detailed analysis of this stage:

-

raw material choice: making sure the exceptional of raw substances is the muse for producing jersey knitted fabric. The raw substances consist of various fibers such as cotton, polyester, spandex, etc. earlier than manufacturing, the raw materials should be strictly decided on, checking the period, fineness, and power of the fibers to make sure they meet manufacturing requirements.

-

Spinning generation: Spinning is the procedure of converting fibers into yarn. during this manner, parameters which includes yarn tension and pace ought to be managed to ensure the uniformity and energy of the yarn. moreover, pre-shrinking remedies are achieved on the yarn to lessen the shrinkage rate of the cloth after manufacturing.

-

Weaving technology: Weaving is the process of interlacing yarns to shape material. Jersey knitted fabric generally use warp knitting or weft knitting procedures. at some stage in weaving, the operation reputation of the machine need to be monitored to make sure the accuracy of the weaving needles and weaving velocity, to be able to assure the flatness and density of the material.

-

Dyeing and Printing: Dyeing and printing are the key steps to impart coloration and styles to jersey knitted fabric. at some stage in the dyeing procedure, the concentration, temperature, and time of the dye must be controlled to make sure even color and sturdiness. when printing, attention should be paid to the readability of the sample and the vibrancy of the colors.

-

finishing: completing is a series of bodily and chemical remedies achieved at the fabric, along with setting, softening, and anti-wrinkling. these treatments can decorate the comfort, durability, and functionality of the material.

-

quality requirements: the important thing to excellent manipulate lies in strict first-class standards. The inspections include:

-

look Inspection: take a look at for any defects which include tears, shade variations, or streaks inside the cloth.

-

Dimensional balance trying out: degree the shrinkage rate of the cloth to make sure dimensional balance.

-

power trying out: check the fabric’s tensile power, tear strength, and different residences to make sure its utilization energy.

-

shade Fastness trying out: take a look at the color fastness of the material to save you shade fading for the duration of washing.

-

capability checking out: For precise functional fabrics including UV protection or antibacterial, carry out corresponding capability checks.

-

non-stop improvement: fine manipulate is a non-stop improvement technique. through accumulating customer feedback and analyzing production information, the manufacturing method is continuously optimized to improve product quality.

through the above excellent manipulate and inspection standards, the manufacturing of jersey knitted fabrics can ensure their incredible overall performance and properly consumer enjoy. As consumers’ pursuit of fabrics continues to rise, strict high-quality manage becomes a key aspect in corporate competitiveness.