Jersey 55: Revolutionizing Football Jersey Clothing with Digital Printing Technology

The jersey, as a symbol of wearing spirit, displays the inheritance of sports lifestyle thru its manufacturing techniques, material choice, and design philosophy. It also embodies the fusion of era and art. In this text, we can delve into the marketplace comments, purchaser opinions, and destiny tendencies of the jersey industry, aiming to comprehensively examine the development trajectory of this field.

Explanation of the Manufacturing Process of Football Shirts

in the realms of sports like football and basketball, jerseys are not simply the athletes’ armor, however additionally a image of logo image and group spirit. the manufacturing procedure of jerseys involves a couple of ranges, that are specified under.

cloth selection and Pretreatment: the first step in jersey manufacturing is the selection of the right fabric. common fabrics include synthetic fibers such as polyester, cotton, and spandex, as well as herbal fibers like cotton and linen. these fabrics require pretreatment earlier than use, along with dehairing, bleaching, and placing, to ensure the first-rate of the cloth and the easy progress of next processing.

slicing and assembly: After pretreatment, the fabric is reduce in line with the jersey’s style and size. Precision in cutting is essential to ensure correct pieces for the assembly method. expert sewing strategies are used at some stage in assembly to make sure that the seams are strong and aesthetically eye-catching.

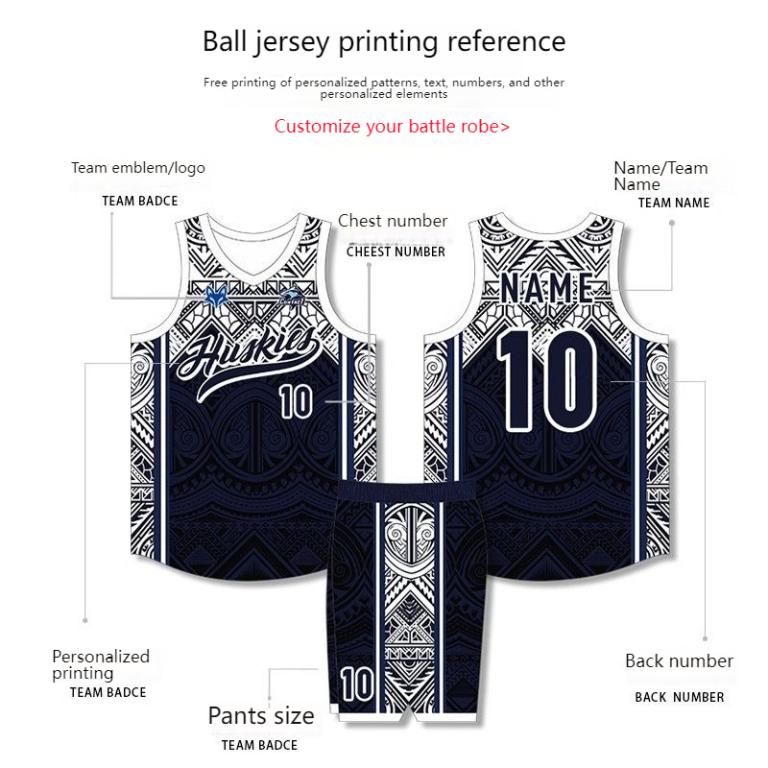

virtual Printing generation: digital printing era is extensively used in modern jersey manufacturing. high-precision printing device is used to at once print styles, crew trademarks, numbers, and other records onto the jerseys, which now not only improves manufacturing efficiency but additionally guarantees the readability of the patterns and the vibrancy of the colors. The jersey 55 series makes use of this technology for personalised customization.

sewing strategies: sewing is a essential part of jersey manufacturing. every element, from the collar, cuffs to the hem, requires cautious sewing. expert stitching machines make sure even stitching and neat thread lines. similarly, reinforcement is applied to important regions such as epaulettes and wallet to decorate the sturdiness of the jersey.

Embroidery techniques: except virtual printing, embroidery is also a not unusual decorative technique on jerseys. first-class embroidery is used to stitch elements inclusive of team names, sponsor emblems onto jerseys, which not handiest elevates the jersey’s repute however additionally complements logo recognition.

useful design: modern-day jerseys also emphasize functionality at the same time as maintaining aesthetics, which includes breathability, moisture-wicking, and antibacterial houses. those functionalities are performed via superior fabric generation and craftsmanship. The jersey 55 series completely embodies these useful designs.

very last Inspection and Packaging: After finishing all the producing techniques, jerseys go through complete inspection. This consists of checking dimensions, colors, patterns, and sewing pleasant to ensure that every jersey meets the same old. Upon passing inspection, the jerseys are packaged and geared up for shipment.

the manufacturing method of jerseys is a complicated one, with every stage from cloth selection to very last inspection being crucial. through high-quality craftsmanship and superior era, it’s far possible to produce jerseys which are each beautiful and sensible. The jersey 55 series, as an incredible example, has gained marketplace popularity for its high excellent and personalized layout.

Material Selection and Performance Criteria

in the manufacturing system of sports activities jerseys, fabric choice is a essential element. underneath is an in depth evaluation of the jersey substances and their performance signs:

-

material Density: The density of the jersey material at once affects its breathability and moisture-wicking homes. excessive-density fabrics provide higher guide and sturdiness, but may additionally reduce breathability. Low-density fabric are extra breathable, making them suitable for athletes in warm climates.

-

Elasticity: The jersey cloth ought to have exact elasticity to make sure freedom of motion for the duration of sports activities sports. Elastic fibers like Lycra (Spandex) are often combined with natural or synthetic fibers together with cotton and polyester to achieve excellent elasticity and restoration after stretching.

three. skin-friendly: due to the fact jerseys come into direct contact with the athlete’s pores and skin, the fabric should have true pores and skin-friendly homes to reduce friction and irritation. Cotton, with its natural and tender texture, is extensively famous, even as artificial fibers like nylon and polyester also can provide a comfortable feel.

four. Abrasion Resistance: Jerseys are challenge to friction all through use, especially in areas just like the shoulders and elbows. fabrics with precise abrasion resistance can keep their authentic form over time, extending the lifespan of the jersey.

five. weather Resistance: Jerseys for out of doors sports want to have good weather resistance to withstand wind and rain. water-proof treatments ensure that athletes stay cozy in destructive climate conditions.

-

Moisture-Wicking: high-overall performance jerseys often use unique technologies like Dri-match (Nike) or Coolmax (Anta) to wick moisture faraway from the skin fast through capillary movement, keeping the skin dry.

-

Anti-scent and Antibacterial: Athletes’ sweat can without difficulty breed micro organism all through physical interest, inflicting odors in apparel. fabrics with antibacterial and odor-resistant properties can correctly inhibit bacterial growth, extending the cleansing cycle of the jersey.

-

Lightfastness: outdoor sports activities jerseys want to have a certain diploma of lightfastness to lessen the harm to fibers from ultraviolet mild. fabric with true lightfastness preserve their color greater durably after lengthy-term publicity to the solar.

-

Antistatic: fabrics with antistatic houses can effectively reduce friction among clothing and the frame throughout exercise, minimizing pain as a result of static power.

-

lightweight: present day jerseys are more and more focusing on lightweight designs to beautify comfort and performance for athletes. the selection of lightweight substances, reducing the overall weight of the jersey, is a key element in enhancing performance.

while choosing substances, jersey manufacturers want to consider elements including fee, environmental friendliness, and sturdiness to ensure that the jerseys produced meet the expert desires of athletes and still have a aggressive market benefit.

Digital printing technology application on football jerseys

The virtual printing era plays a important function within the manufacturing of soccer jerseys, with the following particular applications:

-

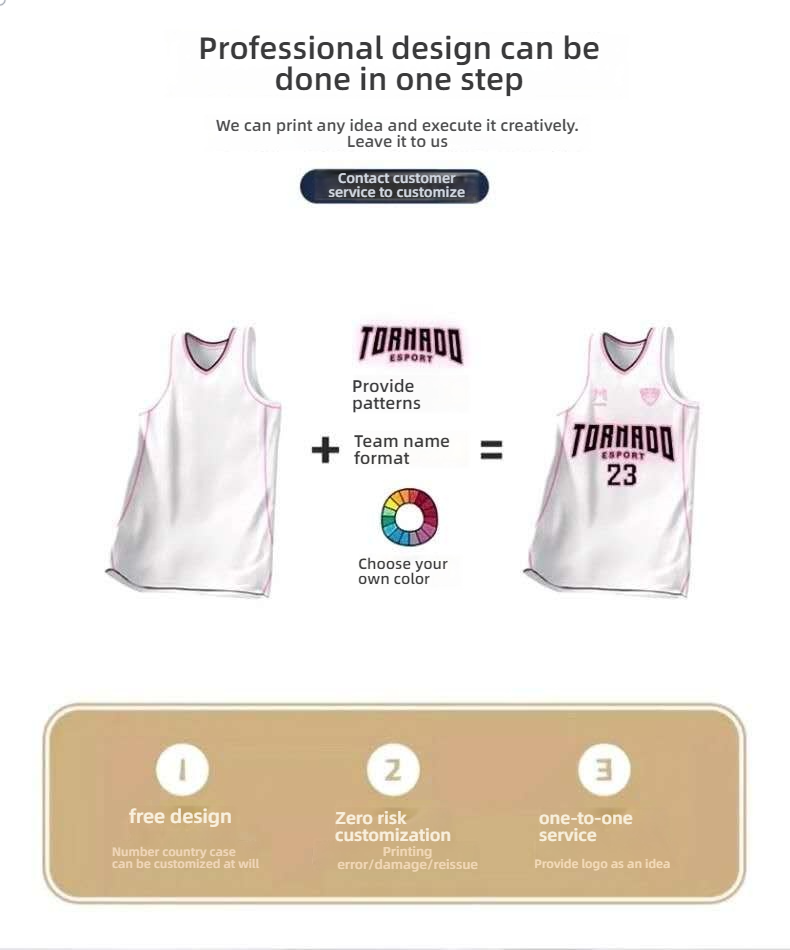

Personalization: virtual printing technology permits for distinctly personalized designs on jerseys, with out the want for huge-scale production, as a result enabling the individuality of every jersey. by means of immediately printing patterns and textual content onto the material, players’ names and numbers may be accurately imprinted in targeted positions, assembly the needs of both expert and novice groups for customization.

-

excessive colour replica: conventional printing strategies frequently conflict to reap high colour fidelity, while digital printing can appropriately mirror the colours from the design drafts, ensuring that the patterns and symbols on the jerseys are bright, clear, and consistent with the logo and team’s visible identity gadget.

three. pleasant sample element: digital printing can produce extraordinarily first-rate styles, even complicated pix and sensitive lines, which is crucial for info like logo sponsor logos on the jerseys.

-

sturdiness Enhancement: thru special inks and printing strategies, the patterns revealed with the aid of virtual printing on jerseys have higher wash and UV resistance, are much less vulnerable to fading, and extend the lifespan of the jerseys.

-

Environmental advantages: digital printing does now not require a large wide variety of printing plates, lowering the consumption of chemical compounds and the generation of waste, aligning with cutting-edge environmental ideas. furthermore, the inks used in virtual printing are generally biodegradable, having a smaller environmental effect.

-

speedy response: In pressing situations, which includes while a team needs to exchange jersey colorations or calls for the urgent production of a specific quantity of jerseys, digital printing generation can quickly fulfill those needs, satisfying time-touchy needs.

-

Versatility: virtual printing era isn’t always constrained to flat styles and also can be carried out to 3-dimensional items, such as 3-dimensional patterns and hot stamping consequences on jerseys, adding visual impact and distinctiveness to the jerseys.

eight. Technological upgrades: With technological advancements, the system for digital printing is constantly upgraded, with extensive enhancements in printing speed and resolution, making its application in jerseys more sizable and efficient.

thru these packages, digital printing generation has added about progressive changes in jersey manufacturing, now not only improving the visual enchantment of the jerseys however also meeting the demands of current sports activities advertising and customized customization.

Uniform Number and Logo Design

virtual printing generation, with its excessive precision and flexibility, plays a considerable role within the production of soccer jerseys. underneath is a detailed description of its software in jersey layout:

The numbering on soccer jerseys is outlined using virtual printing, making sure readability whilst also allowing for personalized customization. The printing process for the numbers generally follows those steps:

-

specific format: Designers meticulously arrange the numbers based at the jersey’s average fashion and format, ensuring their placement and proportions are appropriate at the jersey.

-

specialised Inks: digital printing for football jerseys uses a unique thermal switch ink, that is durable and resistant to wear and washing, forming a company pattern on the jersey.

-

excessive-decision Printing: via excessive-decision printers, digital printing era can print numbers as excessive-definition pics, even truly supplying the quality edges of the numbers.

-

customized Customization: virtual printing lets in for the man or woman printing of every quantity, meaning each player’s jersey range can be custom designed consistent with non-public preferences or team traits.

five. diverse substances: virtual printing technology is suitable for diverse jersey materials, along with cotton, polyester, and polyester, ensuring the attachment and visible effects of the numbers are assured.

In phrases of brand layout, the emblems on soccer jerseys consist of team trademarks, sponsor emblems, and have the subsequent design features:

-

emblem Placement: the site of the emblems have to don’t forget the jersey’s basic stability and aesthetics, normally placed on the front and back of the jersey.

-

pattern layout: The design of the trademarks have to be simple, awesome, and smooth to understand, whilst also aligning with the crew’s visual photo.

-

colour Coordination: the colours of the emblems need to harmonize with the jersey’s foremost shade scheme, fending off any abruptness or distraction.

four. cloth choice: emblems are typically crafted from the same material as the jersey to ensure consistency and durability of the general appearance.

five. Texture treatment: To enhance visual intensity, emblem designs may additionally incorporate techniques consisting of embossing or gold foil stamping, making the brand extra 3-dimensional and upscale.

With the aid of digital printing era, jersey brand layout may be greater diverse, with features which include gradients and 3-D outcomes, making the jerseys no longer simplest functional but also artistic and visually appealing. moreover, the speedy reaction functionality of digital printing drastically shortens the production cycle of jerseys, permitting the success of pressing orders.

Production Process and Quality Control

From uncooked cloth procurement to completed product delivery, the production procedure of group jerseys strictly follows the subsequent steps:

-

raw fabric Inspection: earlier than production, a strict satisfactory inspection is carried out on substances consisting of fabric and threads to ensure that every one substances meet global standards and are unfastened from defects.

-

slicing: The cut material is taken care of by using coloration and size in step with the jersey pattern to make certain correct sizing for each piece.

three. Labeling: Numbers, team emblems, sponsor trademarks, and other markings are affixed to the jerseys to make sure accurate placement and clear styles.

four. stitching: professional sewing machines are used to stitch the jerseys according to design specs, which includes info including sleeve cuffs, collars, and hemlines.

-

warmth switch Printing: The styles on the jerseys are warmth transferred to make certain that the patterns are long lasting and do now not effortlessly peel off.

-

exceptional Inspection: every jersey is inspected throughout the stitching method to ensure there are not any tears or free seams.

-

Washing: The finished jerseys are washed to get rid of excess glue, oil stains, and other impurities to preserve cleanliness.

eight. Drying: The washed jerseys are dried to make sure they’re flat and free of wrinkles.

-

Inspection and Packaging: The completed jerseys are checked for any defects after which packaged.

-

cargo: The inspected jerseys are packed into bins for transport.

In terms of high-quality manipulate, the following factors are specifically focused on:

-

cloth great: Strictly manipulate uncooked material procurement to make certain that fabrics and threads meet international requirements.

-

manufacturing process: Standardize the manufacturing technique to make certain that every step meets requirements and decreases human error.

-

system renovation: frequently keep and service production device to ensure stable operation and enhance production efficiency.

-

employee education: make stronger worker training to beautify operational talents and duty, lowering human errors.

-

best tracking: set up more than one nice inspection points at some point of the manufacturing system to ensure product first-rate.

-

very last Product Inspection: behavior a comprehensive inspection of the finished jerseys, which includes size, color, styles, and seams, to make sure there aren’t any exceptional issues.

-

consumer feedback: accumulate patron feedback, make upgrades primarily based on issues, and enhance product nice.

thru these production strategies and pleasant manage measures, make certain that every jersey meets standards and satisfies patron demands.

55 series feature analysis

The fifty five collection of jerseys stands proud in the market with its specific functions, which can be designated as follows:

-

top rate material: The fifty five collection jerseys are crafted from materials that offer extremely good breathability and moisture-wicking homes, making sure comfort for athletes at some stage in excessive matches.

-

personalized design: The jerseys on this series feature unique designs with unique patterns and coloration combos, now not handiest reflecting the group’s iconic elements but additionally showcasing the uniqueness of the athletes.

-

practical information: The fifty five series specializes in capability in its details, including adjustable cuff designs that allow athletes to adjust their attire based totally on weather conditions, and a chest pocket that is each practical and aesthetically appealing.

four. Optimized fit: The match of the jerseys in this series has been cautiously designed to be frame-hugging with out restricting movement, supplying athletes with an better performance revel in.

five. safety Signage: The 55 collection emphasizes protection signage in its colors and patterns, together with reflective strips and warning shades, to improve visibility for athletes in low-light or nighttime situations.

-

Abrasion-Resistant treatment: to extend the lifespan of the jerseys, the fifty five collection has been handled in regions liable to put on, together with strengthened stitching and abrasion-resistant coatings.

-

method: The fifty five collection takes an approach in cloth selection and production, the use of biodegradable materials to reduce environmental impact.

eight. relaxed cut: The slicing of the 55 collection jerseys considers human engineering, making sure that wearers are not confined for the duration of movement and have sufficient area for activity.

nine. expert-stage overall performance: The series ambitions for expert-grade requirements in overall performance, including short-dry moisture conversion generation, which allows athletes modify frame temperature quickly to keep height aggressive circumstance.

- style Trendiness: The 55 series maintains up with style developments, always introducing progressive designs to satisfy clients’ demands for customization and fashion.

via these functions, the 55 series of jerseys is not simplest a functional sports clothing however also a mix of favor and era, designed to provide comprehensive assist to athletes and assist them showcase their pleasant on the field.

Market feedback and consumer reviews

The utility of virtual printing generation on football jerseys drastically complements product customization and first-class. This era now not most effective lets in for complicated styles and first-class textual content to be printed directly onto jerseys, but also guarantees vibrant and sturdy colours.

The jersey cloth undergoes special treatment to make sure the adhesion and sturdiness of the digital printing. This material features houses including wrinkle resistance, smooth washing, brief drying, at the same time as nevertheless keeping breathability and comfort. digital printing machines use specific nozzles to at once onto the material, forming the patterns.

In phrases of pattern layout, digital printing era gives extra flexibility and creative area. Designers can use various colours and gradient outcomes to offer crew emblems, numbers, sponsor logos, and other elements in a especially creative way. This generation can also obtain localized printing, allowing for the suitable positioning of numbers and identifiers on particular areas consisting of sleeves and chests.

shade constancy is another predominant advantage of digital printing era. by way of adjusting printing parameters such as ink awareness, nozzle pressure, and, it guarantees that the patterns at the jersey closely match the real shades, fending off the shade discrepancy issues which can stand up with conventional printing.

digital printing era presents rich design opportunities for the layout of jersey numbers and identifiers. The font length, style, and colour of the jersey numbers may be adjusted according to design requirements, and even 3-dimensional effects may be added to make the numbers more distinguished and.

In phrases of best control, digital printing technology keeps strict standards. during the production process, every step is concern to great inspections to make certain the clarity of the styles, the accuracy of the colors, and the integrity of the fabric. moreover, due to the customised nature of virtual printing, every jersey can be independently inspected for excellent, making sure the exceptional of each product.

marketplace feedback indicates a excessive recognition of virtual printing soccer jerseys by customers. specially amongst younger purchasers, who’re more inclined towards personalised and fashionable jerseys. virtual printing soccer jerseys meet this demand at the same time as additionally pleasing professional athletes’ requirements for performance and luxury.

consumer opinions are predominantly high quality, with consumers noting that digital printing jerseys not handiest look stylish however also provide vast improvements in durability and luxury. Many consumers say that sporting such jerseys complements group spirit and boosts personal self belief on the sector.

In summary, the application of virtual printing technology on soccer jerseys not simplest enriches the design style of the jerseys however additionally improves the nice and market competitiveness of the goods. With the continuous development of era, the future application of digital printing inside the sports goods industry is predicted to be even more big.

Industry Trends and Future Development Outlook

in the virtual age, the sports clothing industry is experiencing a wave of innovation and transformation. The increasing call for for personalization from consumers is driving the diversification of jersey design. here are a few insights into enterprise developments and future tendencies:

-

personalised Customization as a brand new trendWith technological advancements, customized jersey customization is turning into an increasing number of not unusual. clients can pick from exceptional colorings, styles, texts, and numbers to create a completely unique private jersey. This customized provider now not handiest satisfies the personalized desires of consumers but also gives brands with greater opportunities to interact with their customers.

-

good sized application of smart substancesinside the destiny, jerseys will increasingly comprise clever substances which include temperature-regulating fibers and antibacterial odor-resistant materials. those substances now not handiest decorate the comfort of jerseys however additionally offer practical advantages consisting of tracking sports activities records and tracking health conditions.

-

Optimized virtual production methodsDigitalization of manufacturing techniques will improve performance and reduce waste. through the usage of the internet of things and intelligent manufacturing technology, each stage of the production process can be monitored and changed in actual-time, making sure consistency in jersey best.

-

Sustainable development gains TractionThe upward push of environmental consciousness has made sustainability a key attention in jersey manufacturing. Adopting biodegradable materials, decreasing packaging, and optimizing the deliver chain are all techniques that assist lessen the environmental impact of jersey production.

five. Intensified emblem Differentiation competitionin the fierce market opposition, brand differentiation has grow to be critical. within the future, jersey producers can pay extra attention to conveying brand memories and emotional values, shaping brand pix thru particular jersey designs, substances, and functionalities to attract target customer corporations.

-

move-enterprise Collaboration and Innovation FusionThe sportswear enterprise turns into extra open, undertaking move-industry collaborations with fields together with fashion and generation. This fusion will carry new layout standards, technologies, and substances, riding non-stop innovation inside the industry.

-

client enjoy on the coreThe enhancement of client experience will the complete industry chain. From design, manufacturing, to income, each link will consciousness on improving person experience, along with handy purchasing channels and complete after-sales services.

eight. virtual advertising and Social Media have an effect onWith the recognition of social media, digital advertising has grow to be an critical way of promoting sportswear brands. through precise marketing and content material advertising and marketing, brands can communicate greater at once with customers and build emblem loyalty.

In precis, the future improvement tendencies of the sports wear enterprise will cognizance on personalized customization, clever materials, virtual production, sustainability, logo differentiation, pass-industry collaboration, client enjoy, and digital advertising and marketing. these developments will collectively pressure the industry ahead, bringing richer and greater customized products and services to purchasers.