Jersey 24: The Ultimate Suit for the Soccer Field – Perfectly Suitable Football Jersey Design

within the sports realm, jerseys are not simplest the war apparel for athletes to show off their style, but additionally a provider of brand subculture and technological innovation. this article will explore the jersey design called jersey 24, analyzing its unique design philosophy inside the software of sports activities device, and its marketplace have an impact on.

within the manner of producing a soccer jersey, from design to finished product, each step embodies professionalism and meticulousness. here is a detailed evaluation of the jersey manufacturing procedure:

within the layout phase, designers use CAD software to create patterns for the jerseys based totally at the crew’s logo, hues, and marketplace call for. At this degree, designers must not handiest don’t forget aesthetics however additionally make sure the consolation and capability of the jerseys during play.

cutting and layout are key degrees within the manufacturing method. in this phase, technicians reduce the cloth accurately in step with layout drawings. the selection of fabric is critical, because it must ensure the jersey’s breathability, durability, and compliance with environmental requirements. After reducing, the fabric is arranged via a layout gadget to make sure manufacturing efficiency.

sewing is the center in jersey making. in the course of the stitching system, workers use specialized sewing machines to sew the jerseys in keeping with the drawings. To ensure the flatness and beauty of the jerseys, workers need to have tremendous stitching abilities. additionally, the stitching procedure might also contain the set up of accessories which includes zippers and labels.

Embroidery and printing are decorative tiers in jersey production. Embroidery era can present complex styles and text, including team names and player numbers. Printing is used to switch patterns or text into jerseys with durable ink. This degree calls for excessive standards of shade constancy and clarity.

quality inspection is an vital step in ensuring jersey best. at some stage in production, pleasant inspectors take a look at the jerseys from diverse components which includes material, stitching, and embroidery to make sure each product meets requirements. Inspection、、.

The packaging section calls for distinct packaging of every jersey to save you harm at some stage in transportation. The design of the packaging field ought to reflect the brand picture while making sure the protection of the jerseys in the course of transit.

Logistics distribution is an necessary a part of the jersey manufacturing method. according to order necessities, finished jerseys are looked after, packaged, and delivered to customers via logistics channels.

The complete jersey manufacturing technique demonstrates strict control from layout to finished product. thru this process, a jersey that is each stunning and sensible is born, meeting the wishes of diverse customers.

Material Selection and Performance

the choice of cloth for jerseys has an instantaneous impact on their overall performance. here is a detailed description of different substances and their overall performance traits:

-

Cotton: A conventional material commonly used for jerseys, imparting precise moisture-wicking and breathability, offering comfort while worn. Cotton jerseys are soft, breathable, and appropriate for spring and summer time seasons. however, cotton fabric is prone to wrinkling and deformation and does no longer dry speedy, making it mistaken for excessive-depth sports activities.

-

Nylon: Nylon is understood for its wonderful put on resistance and elasticity, making it ideal for sports jerseys. Nylon jerseys are durable and appropriate for lengthy-time period put on. however, they have got poor moisture-wicking residences and common breathability.

three. Lycra (Spandex): Lycra is a artificial fiber with extremely high elasticity, regularly combined with cotton or nylon. The addition of Lycra improves the stretchiness of jerseys, improving consolation during physical hobby. Lycra additionally has suitable moisture-wicking homes, helping to keep the body dry.

-

Polyester (Polyester Fiber): Polyester is renowned for its advanced wear resistance, wrinkle resistance, and antistatic homes, making it suitable for jerseys. Polyester jerseys have suitable breathability, do now not deform effortlessly, and are appropriate for various climates and levels of bodily pastime.

-

Composite of Lycra and Polyester: Combining Lycra with polyester can completely utilize the benefits of both materials. This composite material offers incredible elasticity, breathability, and wear resistance, making it suitable for excessive-overall performance sports jerseys.

-

practical fabric: With technological advancements, useful fabrics are broadly used in jersey production. Examples include breathable membranes and antibacterial fabric. Breathable membranes ensure top breathability at some point of physical activity, even as antibacterial fabric correctly inhibit the growth of bacteria, improving the hygiene overall performance of jerseys.

-

excessive-stop fabric: some high-give up jerseys use special fabric, which includes carbon fiber and titanium alloy fibers. these fabrics have unique residences, including light-weight, high power, and antistatic, imparting athletes with a higher sports enjoy.

-

fabric Dyeing and Printing: The dyeing and printing procedures of jerseys additionally have an impact on their performance. dyeing strategies make certain that the colours of jerseys are shiny, washable, and fade-resistant. Printing technology should assure that the patterns are clean and now not at risk of peeling.

In precis, the choice of jersey material is carefully associated with its performance. high-quality fabrics now not only beautify the comfort of jerseys but also offer athletes with higher overall performance. within the jersey production technique, suitable substances must be chosen based totally on one-of-a-kind needs to achieve top-quality performance.

Customized Services and Market Demand

within the sports activities enterprise, custom designed jersey services have grow to be a prime spotlight. As customers’ pursuit of personalization and forte keeps to grow, market call for has prompted jersey factories to enlarge into the area of custom designed offerings, building upon conventional manufacturing models.

custom designed services typically encompass the subsequent aspects:

-

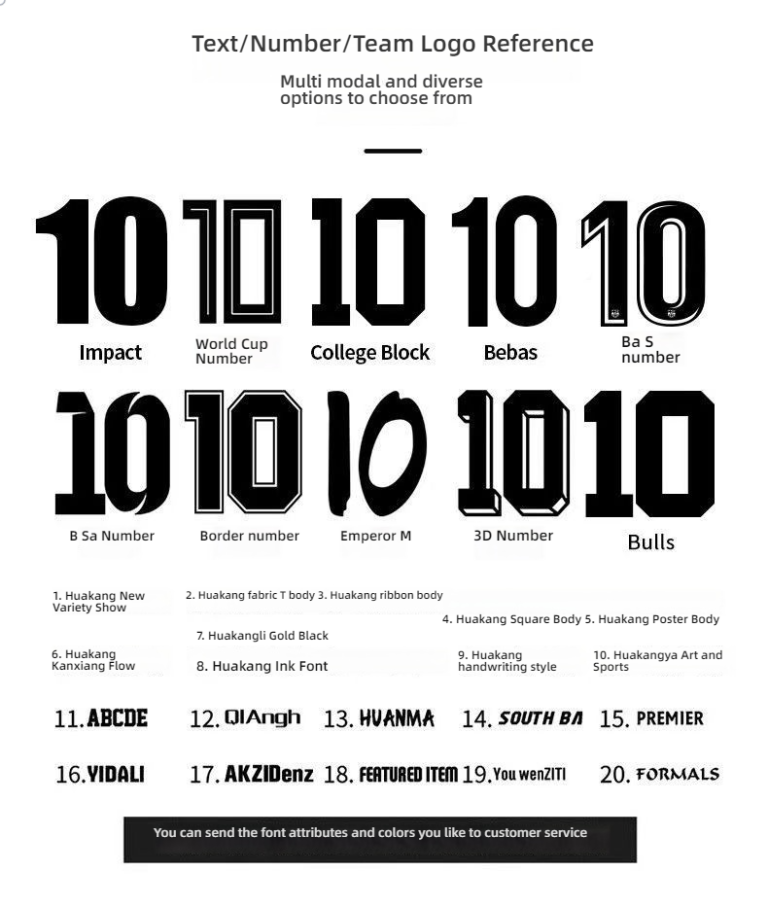

layout Customization: purchasers can pick jersey shades, styles, numbers, and other factors based on their choices or particular event desires. This requires jersey factories to have wealthy layout competencies and bendy manufacturing approaches to recognize the diverse creative ideas of customers.

-

length Customization: With significant differences in frame shapes amongst individuals, standardized jersey sizes frequently fail to meet all people’s desires. therefore, jersey factories offer personalized customization offerings to make sure that customers can wear them simply and flow freely.

three. logo Collaboration: Many businesses or individuals intention to beautify logo photograph or organize occasions via customized jerseys. in this method, jersey factories act as a bridge, combining consumer needs with brand characteristics to create custom designed jerseys with memorable importance.

four. personal Autographs: well-known athletes and enthusiasts are keen on leaving their autographs on jerseys as souvenirs or memorabilia. Jersey factories want to make sure the authenticity and aesthetics of the autographs to meet this unique call for.

five. cloth choice: In customized services, clients can choose appropriate jersey materials based totally on factors such as weather and forms of sports activities. for example, breathable polyester fiber materials for hot climate and heat wool or synthetic fiber materials for bloodless climate.

-

functional design: With the improvement of technology, functional jersey layout is increasingly more valued. capabilities consisting of antibacterial and scent-resistant, moisture-wicking, and UV protection can all be contemplated inside the customized offerings.

-

supply Chain control: to fulfill ever-converting market demands, jersey factories need to set up an efficient deliver chain gadget. This consists of close cooperation with partners together with fabric providers, printing factories, and packaging factories to ensure the smooth development of custom designed offerings.

-

After-income carrier: even as imparting customized offerings, jersey factories additionally want to pay attention to after-sales carrier. This consists of steerage on jersey cleaning and preservation, as well as return and trade policies to enhance client pride.

custom designed offerings play an more and more essential role inside the jersey marketplace. As customer demand for customization keeps to grow, jersey factories must innovate whilst maintaining product great and overall performance to satisfy market demands. This now not best facilitates beautify logo photograph however also brings greater marketplace competitiveness to the company.

Application of technological innovation in soccer jersey manufacturing

Technological innovations in the football jersey production discipline are in general contemplated in the following factors:

-

application of high-performance fabricsThe development of soccer jersey fabric continuously aims for characteristics which include lightness, breathability, and sturdiness. present day jerseys utilize excessive-performance fabric, inclusive of people with nanotechnology-primarily based breathable membranes, that can maintain power and sturdiness at the same time as efficaciously improving comfort. additionally, a few jersey fabric comprise antibacterial and smell-resistant houses to fulfill the desires of athletes in excessive-temperature and high-humidity environments.

-

3D Printing technologyThe application of 3D printing era in jersey manufacturing makes customization viable. by using scanning an athlete’s body, designers can create jerseys that in shape individual frame contours precisely, improving the sporting revel in and lowering fabric waste.

-

Integration of smart generationclever generation included into jersey production, consisting of embedded temperature sensors and heart fee monitors, can monitor athletes’ education fame and fitness indicators in real-time. those smart features not most effective enhance the functionality of the jersey but also offer valuable statistics help for coaches and athletes.

-

Structural Optimization layoutThe structural design of jerseys has been constantly optimized to satisfy the unique wishes of various sports activities. for example, football jerseys have shoulder designs that concentrate on protection to lessen the danger of injury in the course of confrontations; basketball jerseys, then again, emphasize flexibility and freedom of motion at some stage in play.

-

Innovation in Adhesive and sewing techniquesThe adhesive and stitching strategies used in modern jerseys are greater delicate, including warmness bonding generation, which reduces the effect of stitching strains on the jersey’s appearance at the same time as improving durability. furthermore, laser cutting generation is used for unique processing, making the jersey edges smoother and decreasing flaws that may get up from traditional slicing and stitching.

-

Use of materialsIn reaction to environmental trends, jersey manufacturing is beginning to use recyclable substances, along with recycled polyester fibers, which no longer only reduce environmental pollutants however also decrease manufacturing costs.

-

Personalization and Artistrythrough technological innovation, jersey personalization designs have become extra numerous. Designers can use digital printing era to create complicated patterns and hues on jerseys, making every piece precise in inventive fee.

through those technological innovations, soccer jerseys are not just sports activities gadget; they’re products that combine fashion, era, and capability, assembly a variety of marketplace needs and diverse choices.

Quality Control and Inspection Standards

The first-class manage and trying out standards in the production manner of football jerseys are crucial for making sure product nice. underneath is a detailed description of this stage:

-

raw fabric selection: the producing of football jerseys starts offevolved with the uncooked substances, together with the material, accessories, and sewing threads. best control starts offevolved at the supply, with strict supplier screening to make certain all uncooked substances meet international requirements and don’t have any harmful materials.

-

cloth checking out: As the main thing of the jersey, the excellent of the fabric immediately influences its comfort and durability. The testing process consists of fiber composition evaluation, colorfastness assessments, and breathability assessments to make sure the cloth meets the requirements for overall performance.

-

stitching technique tracking: in the course of the sewing technique, info inclusive of the sewing thread, sew styles, and seams are strictly monitored. excessive-precision checking out system is used to check for even stitching and neat sew patterns, ensuring the stability of the sewing technique.

-

3-d Stereo reducing: the usage of 3-d stereo slicing technology, the jersey is cut according to ergonomic ideas to make sure an excellent in shape and beautify wearing consolation. moreover, via stereo reducing, cloth waste is minimized.

-

waterproof and Breathable function checking out: For jerseys that require water resistant and breathable capabilities, professional exams are conducted to ensure they could successfully wick away sweat during exercising, prevent dampness, at the same time as maintaining breathability.

-

Tensile power and Abrasion Resistance checking out: professional tensile testing device is used to check the tensile strength of the jersey, ensuring its stability all through exercising. on the equal time, abrasion resistance is examined to make sure the sturdiness of the jersey over long-term use.

-

Antimicrobial and smell control treatment: The jersey is treated with antimicrobial and odor manipulate, the usage of unique tactics to make the jersey self-cleaning, decreasing bacterial boom, and enhancing the wearing revel in.

eight. Flame Retardancy checking out: Flame retardancy exams are carried out on the jersey according to global standards to make sure it meets safety necessities in case of an twist of fate.

nine. very last Product Inspection: in any case techniques are finished, a comprehensive final product inspection is completed, including appearance checks, useful tests, and length measurements, to ensure each jersey meets the standard requirements.

- Packaging and Labeling: After pleasant manipulate is passed, the jerseys are packaged, and applicable records is categorized in step with rules, which includes product call, logo, model, and size, to ensure clients can really apprehend product facts.

thru these exceptional control and trying out standards, jersey factories can make certain that each product meets requirements and satisfies patron needs for sports activities equipment.

Market trends and brand collaborations

inside the modern marketplace environment, the sportswear industry is undergoing a sequence of modifications, and the subsequent are descriptions of several factors related to marketplace tendencies and emblem collaborations:

overall performance substances Take center stage, with light-weight and Breathable mixtures

As sports activities technology advances, the choice of fabric for sports wear is increasingly centered on performance. excessive-performance materials which include polyester, spandex, and polyamide are extensively used, which no longer simplest offer amazing wear resistance and elasticity but also make sure the lightness and breathability of the sportswear. brands aren’t simplest pursuing aesthetic attraction however also that specialize in enhancing the comfort and performance of athletes.

developing demand for personalisation, assembly diverse marketplace desires

The pursuit of personalization by purchasers is using the sportswear enterprise towards customized services. manufacturers are offering alternatives for custom designed styles, crew names, numbers, and extra to meet the wishes of various customers. custom designed offerings aren’t limited to expert sports activities groups but also consist of amateur groups, faculty sports activities groups, or even creditors, making them substantial contributors on this marketplace.

virtual advertising and Social Media increase logo merchandising

In brand collaborations, digital advertising and social media have become essential tools for advertising. thru social media structures, brands can set up direct connections with lovers and customers, unfold brand stories, and decorate brand affect. on the same time, the upward push of online shops and e-commerce structures has provided brands with wider sales channels, promoting the sale of sports wear.

cross-border Collaborations and modern design amplify market boundaries

move-border collaborations among brands have grow to be a brand new market fashion. via partnering with manufacturers in style, amusement, and other fields, sportswear brands can appeal to extra non-traditional clients. similarly, the software of innovative design in sports clothing manufacturing, inclusive of the advent of three-D printing era, makes the styles and functions of sportswear greater numerous, catering to the desires of different situations and consumer organizations.

Sustainability concept incorporated into manufacturing, improving brand photograph

The concept of environmental protection and sustainability has turn out to be deeply ingrained, and sports wear brands are starting to focus on the use of environmentally pleasant substances and decreasing electricity intake inside the manufacturing manner. This approach now not only helps to minimize environmental impact however additionally enhances the emblem’s social obligation photo, attracting extra customers who’re concerned about environmental safety.

statistics evaluation and consumer Insights for specific market Positioning

In emblem collaborations, statistics analysis equipment and consumer perception technologies are broadly applied. by way of analyzing sales statistics, consumer comments, and marketplace developments, brands can more appropriately position the market, regulate their product strategies, and meet the wishes of target customers.

worldwide sports events force logo Collaborations, enhancing worldwide impact

global carrying activities inclusive of the world Cup and the Olympics offer sports clothing manufacturers with possibilities to collaborate with across the world renowned athletes and sports businesses. through those collaborative activities, manufacturers can beautify their worldwide popularity and impact, further increasing their distant places markets.

Jersey size 24’s special design and applications

The layout philosophy of jersey 24 emphasizes the mixture of capability and fashion, with the following distinct descriptions of its unique design and packages:

colour Matching: Jersey 24 employs a diffusion of colour and gradient designs, which not only cater to trendy aesthetics however also permit for changes in shade mixtures based totally on exceptional sports situations and logo photos. for example, the jersey 24 for a sports activities emblem might function the brand’s signature coloration as the main hue, complemented with the aid of vibrant contrasting shades to decorate visible impact.

cloth selection: excessive-tech purposeful fabrics, which includes breathable, short-drying, antibacterial, and UV-resistant substances, are used to make certain consolation for athletes for the duration of intense bodily interest and to defend the pores and skin from outside damage.

cutting generation: Jersey 24 utilizes three-dimensional cutting strategies, designed in step with human ergonomics, to make the jersey greater body-conforming, lowering friction and all through motion, and enhancing athletic performance.

sample layout: The patterns on the jerseys are often carefully integrated with brand tradition or event themes. The sample design of jersey 24 might also consist of complex styles, photographs, or emblem logos, supplied thru embroidery or printing techniques to ensure the readability and durability of the styles.

practical pockets: to fulfill the needs of athletes, jersey 24 is designed with useful pockets which can be handy for wearing small gadgets, consisting of telephones or keys, offering both practicality and aesthetics.

performance testing: in the course of manufacturing, jersey 24 undergoes rigorous performance trying out, inclusive of washability, colour fastness, and elasticity restoration fee, to ensure that the product meets global standards.

marketplace Positioning: The goal purchaser institution for jersey 24 is typically professional athletes and sports activities fans, so its design need to now not best meet the requirements of athletic performance but additionally own a sure stage of style enchantment to draw the eye of young consumers.

Collaboration cases: Jersey 24 has collaborated with several sports brands and golf equipment to provide customized offerings. for example, a positive soccer club selected jersey 24 as its home fit jersey for the brand new season, with an individualized design tailor-made to the club’s characteristics.

marketplace reaction: jersey 24 has obtained advantageous comments in the marketplace, with clients quite praising its capability and fashion, which has additionally earned the brand a good reputation and marketplace share.

After-sales carrier: To enhance client pride, jersey 24 gives comprehensive after-income provider, such as returns, exchanges, and renovation, to make certain that customers receive complete support during use.