How to Find a Reliable Factory for Your Business: Selection Criteria and Quality Control in the Commercial Enterprise Region

in the commercial enterprise region, finding a dependable manufacturing facility associate is crucial. This no longer best issues product quality but additionally pertains to price manipulate and supply chain stability. this article will delve into how to pick out the correct manufacturing facility, offering practical techniques through case research for the readers.

Please clarify the selection criteria.

while choosing a reliable factory, it’s far important to genuinely define your selection standards as the first step. right here are some key factors to make sure your desire aligns along with your business needs:

-

manufacturing capacity evaluation: firstly, you want to evaluate whether or not the manufacturing facility’s production capability can meet your order volume. This consists of knowledge its monthly output, wide variety of production traces, level of automation, and its capability to address emergency orders quickly.

-

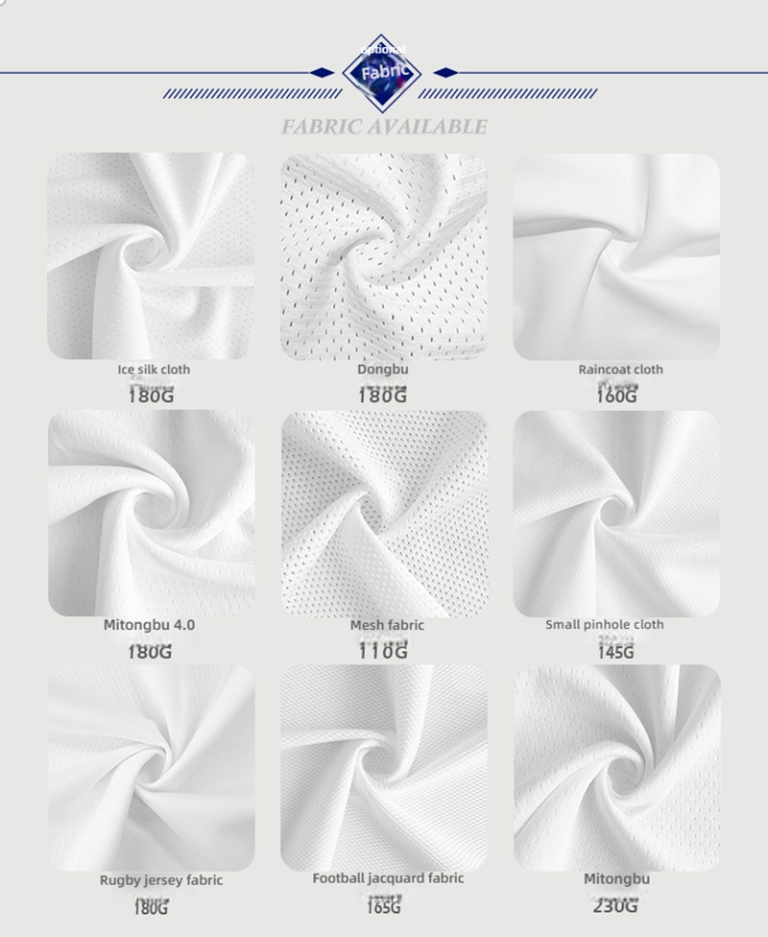

first-class necessities: sincerely outline your high-quality standards, such as substances, tactics, dimensional accuracy, durability, and extra. ensure the factory has the manufacturing generation and great control system to fulfill those requirements.

-

cost-gain analysis: establish a reasonable price range and display screen factories accordingly. evaluate rate fees from distinctive factories at the same time as considering value for money and keep away from compromising pleasant for decrease fees.

-

enterprise experience and qualifications: studies the manufacturing unit’s experience inside the relevant industry, along with the kinds of customers they have served, venture instances, and whether they have applicable enterprise certifications. This helps examine their professionalism and stability.

-

Geography and Logistics: don’t forget the factory’s vicinity and logistics competencies, as these directly impact product delivery times and prices. ensure the region is well-connected for green managing of raw material procurement and product transport.

-

shipping times and versatility: simply define your delivery time requirements and check the manufacturing facility’s on-time shipping fee. additionally, don’t forget their capacity to address order fluctuations, which include their potential to just accept small batch orders or fast regulate manufacturing plans.

-

communique and Collaborative relationship: select a manufacturing unit partner with clean communique and accurate provider attitude. examine their inner communique mechanisms to ensure effective facts transfer and comments at some stage in the collaboration.

-

Environmental protection and Social responsibility: don’t forget whether the factory complies with environmental regulations and fulfills social duties. This no longer simplest pertains to the corporate photo but is likewise a sizable a part of modern corporate social responsibility.

-

Technical help and Innovation capabilities: recognize the manufacturing unit’s technical aid competencies, such as whether or not they provide custom designed solutions and technical guidance. also, take a look at their potential to innovate and constantly enhance.

-

contract phrases and After-income carrier: cautiously review the contract terms to make certain your rights are protected. additionally, apprehend the manufacturing facility’s after-income carrier regulations, consisting of returns, upkeep, and customer support.

by means of thinking about these specified elements, you can make clear your selection criteria and as a consequence filter out the manufacturing unit partners that quality fit your business needs. This not best improves your deliver chain performance however additionally guarantees product best and business stability.

Market Research and Selection

After clarifying your own wishes, market research and choice become essential steps. for the duration of this process, the subsequent information must be paid special attention to:

-

enterprise report evaluation: by means of reviewing industry reports, you may understand the general market traits, the state of affairs of competitors, and the distribution of potential suppliers. This enables pick out factories that experience a great popularity within the enterprise.

-

Exhibition facts series: Attending enterprise exhibitions is an effective manner to fast accumulate data approximately capability providers. On-website, you could at once talk with manufacturing facility representatives to gain product samples, quotations, and corporation introductions.

-

on-line search and assessment: utilising on line platforms along with B2B web sites, expert boards, and social media, you could search for a massive quantity of manufacturing facility facts. evaluating the reputation, ancient critiques, and person remarks of diverse factories can assist slender down the choice range.

-

Reference industry association recommendations: enterprise institutions or chambers of commerce often have endorsed lists of providers, which are generally based totally on enterprise requirements and member opinions and are fantastically credible.

-

Screening Key indicators: After gathering data, display screen primarily based on key signs inclusive of production capacity, product variety, satisfactory manipulate structures, and delivery cycles to ensure that candidate factories meet these requirements.

-

evaluate costs and expenses: charge is an vital aspect in selecting providers, but must not be the only criterion. compare fees from one of a kind factories at the same time as thinking about comprehensive costs which include manufacturing expenses, transportation prices, and after-sales provider.

-

Exclude Non-compliant Factories: during the screening manner, exclude factories that have substandard manufacturing environments, critical quality problems, or violate labor legal guidelines to avoid ability dangers.

-

awareness on deliver Chain stability: study the manufacturing facility’s deliver chain control skills, consisting of uncooked material procurement, production making plans, and stock manage, to ensure lengthy-time period cooperation stability.

-

purchaser reviews and Case research: evaluation present purchaser opinions and case studies to understand the real overall performance and cooperation revel in of the manufacturing unit, which is critical for judging the reliability of the factory.

via these steps, you may correctly display screen out factories that meet the requirements from among many providers, laying a solid foundation for subsequent cooperation.

On-site inspection and assessment

To delve into the factory, one ought to first have a look at the format of the production line to ensure it’s miles affordable, the system is advanced, and whether or not it may meet the needs of mass manufacturing. concurrently, interest should be paid to the orderly nature of the on-website control and the standardization of employee operations, as those at once have an effect on the stableness of product quality.

observe the manufacturing facility’s material management by checking the storage situations of raw substances to make sure they meet standards, and whether or not strict stock and difficulty management structures are in area to save you waste or infection of substances.

Then, behavior an on-site inspection of the production method, being attentive to whether the process flows are clear, the employees’ operations are talented, and whether or not good enough protection precautions are in area. moreover, recognize the production cycle and capacity to make certain the manufacturing facility can meet order deadlines on time.

The cleanliness and hygiene of the manufacturing facility must no longer be disregarded either; a easy and tidy manufacturing surroundings contributes to stepped forward product nice and additionally displays the corporation’s image.

in the meantime, talk with the factory’s control to recognize their company tradition and values, and determine if they align along with your personal commercial enterprise philosophy. also, inquire about the management’s views on industry tendencies and their techniques for handling demanding situations.

have a look at the factory’s employee welfare and advantages, inclusive of salary levels, running hours, and excursion regulations, as these at once relate to worker delight and efficiency.

understand the encircling surroundings of the manufacturing facility, such as transportation, logistics, and supply chain infrastructure, as these factors will effect the manufacturing facility’s operating costs and efficiency. After a comprehensive examination of these factors, assess the general electricity of the manufacturing facility.

Quality Control System

-

uncooked cloth InspectionThe inspection system for uncooked substances in a manufacturing facility is fundamental to making sure product pleasant. have a look at whether or not the manufacturing facility has a strict set of procurement inspection requirements, inclusive of supplier qualification audits, pattern trying out, and batch sampling, to make certain that each batch of raw substances meets the specified high-quality standards.

-

manufacturing system monitoringmonitoring in the course of the manufacturing technique is essential. recognize whether the manufacturing facility has set up monitoring points inside the manufacturing system, along with inspections at key steps, upkeep statistics of production gadget, and operational requirements for employees, all of which at once affect the final pleasant of the product.

-

on-line Detection and Adjustmentwhether or not the manufacturing facility is geared up with on-line detection device, which includes high-precision measuring contraptions and online detection structures, is important. these can screen product dimensions and overall performance in real-time during production and make changes directly whilst deviations occur.

four. final Product Inspection and satisfactory requirementsexamine the manufacturing facility’s final product inspection method, which include inspection gadgets, strategies, and gadget. apprehend if there are clean excellent standards and whether or not these requirements are consistent with international or industry requirements.

-

first-rate information and Traceabilityexceptional records are any other critical element of satisfactory manipulate. determine whether the factory has an which could trace each batch of products, allowing for fast identification of the purpose of nice troubles and the implementation of measures.

-

employee training and focusthe attention and schooling of employees regarding excellent manipulate also are key factors for evaluation. inspect whether or not the manufacturing facility conducts regular pleasant consciousness schooling for employees to make sure that each worker is familiar with and complies with the exceptional management gadget.

-

pleasant development Measureswhether or not the factory has continuous quality improvement measures, such as regular exceptional audits, development initiatives, and employee proposals, reflects the factory’s dedication to great management.

-

patron comments and reactionbe aware of how the factory handles consumer remarks, whether or not it has hooked up an effective client complaint handling mechanism, and whether or not it is able to respond and clear up consumer problems promptly.

through those numerous factors of examination, you may comprehensively assess whether the factory’s best manage gadget is sound and the way efficaciously it is applied, thereby determining whether or not the manufacturing facility can provide merchandise that meet the required requirements.

Contract and Legal Documents

before moving into a cooperation agreement, it is crucial to very well evaluate the following legal documents:

- supplier Qualification certificate

- affirm the manufacturing unit’s official files along with the employer prison individual enterprise License, Tax Registration certificate, and enterprise Code certificates to make sure their felony and compliant operation.

- Product Qualification certificate

- review the factory’s product nice inspection reports and certification certificates, along with ISO first-class gadget certification and CE certification, to make certain that the goods meet applicable requirements.

three. contract phrases– cautiously study the settlement terms, together with transport time, quantities, first-rate requirements, price strategies, and liability for breaches, amongst other key contents.

four. highbrow assets safety– clarify the contract provisions regarding the possession and utilization scope of intellectual property to save you infringement disputes.

five. Confidentiality settlement– sign a confidentiality settlement to guard each events’ commercial secrets and technical statistics from being leaked.

- Dispute decision Mechanism

- determine the dispute decision strategies inside the settlement, inclusive of negotiation, mediation, arbitration, or litigation, to make certain a brief and powerful resolution in case of disagreements.

- After-sales service Commitments

- understand the after-income carrier furnished by the factory, which includes assurance intervals, restore offerings, and elements deliver, to ensure fear-unfastened after-income carrier.

- conditions for settlement change and Termination

- simply outline the conditions and procedures for settlement amendment or termination to prevent unnecessary losses because of agreement changes.

- pressure Majeure Clause

- ensure that the settlement includes a force majeure clause, specifying the rights and obligations of the events in the occasion of natural disasters, war, government moves, and other pressure majeure occasions.

- agreement Attachments

- check the agreement attachments, including technical specs, samples, and quotations, to ensure that the content material of the attachments is consistent with the principle textual content of the contract.

by way of following these steps, you may ensure the comprehensiveness and rigor of the settlement and criminal files, laying a solid foundation for lengthy-term cooperation. on the same time, be aware of the subsequent points:

-

expert prison Opinion: it’s far best to consult a expert legal professional earlier than signing the contract to study the contract content and keep away from capacity criminal risks.

-

clear duty division: The settlement must surely outline the duties and obligations of each parties to avoid issues bobbing up from unclear obligations.

-

flexible Adjustment: during the settlement execution, each events have to preserve communication and flexibly regulate the agreement content material in case of special instances.

-

everyday overview: After the contract is signed, often review the implementation of the agreement terms to make certain that the agreement clauses are successfully enforced.

Price and Payment Terms

whilst evaluating expenses, the subsequent factors need to be considered:

-

marketplace Reference price: examine the marketplace reference costs of comparable merchandise in the identical industry to apprehend the reasonable charge variety within the enterprise, ensuring that the manufacturing unit’s citation falls inside this range.

-

value Composition: Inquire about the distinct value composition of the manufacturing facility, consisting of uncooked materials, exertions, and depreciation of device, to apprehend the factors in the back of the rate.

-

first-class warranty: expenses regularly correlate with product high-quality, ensuring that the fee paid corresponds to the satisfactory received.

-

charge techniques: distinct price techniques can have an effect on capital flow and risk manage. recognize the charge methods generic by the manufacturing facility, which include prepayment, installment bills, or cash on delivery.

five. charge Fluctuations: Ask whether or not the fee is constant or situation to trade, as well as the conditions and frequency of any changes.

-

extra expenses: Be aware about any extra fees, together with transportation, packaging, and tariffs, which may additionally affect the very last cost.

-

charge Adjustment Mechanism: apprehend the mechanism for charge changes, inclusive of based on market fluctuations or modifications in uncooked material expenses, to ensure charge transparency.

-

special quotation: Request a detailed quotation from the manufacturing unit, together with itemized charges, to avoid pointless disputes in a while.

nine. Negotiation area: consider negotiation space primarily based on marketplace situations and the factory’s bargaining electricity to at ease a more favorable fee.

- long-term Cooperation consideration: If planning to set up a long-term relationship with the factory, keep in mind bulk purchases or lengthy-term orders to negotiate more favorable expenses.

whilst figuring out price phrases, the following points have to be noted:

-

payment percentage: Allocate the percentage of prepayment, progress payments, and very last fee in step with the assignment’s progress and hazard.

-

price time table: sincerely outline the time for each charge node to make certain clean capital drift.

three. charge approach: choose a safe and convenient payment method, which include financial institution transfer or electronic fee.

- charge situations: really outline the charge conditions, along with upon receipt of fee or upon passing inspection.

five. Default legal responsibility: If one celebration defaults, truely outline the default liability and reimbursement standards.

-

Dispute resolution: Agree on the dispute resolution method, which include negotiation, arbitration, or litigation.

-

Confidentiality Clause: If there are any commercial enterprise secrets and techniques involved, a confidentiality clause ought to be agreed upon inside the settlement.

eight. settlement modification: sincerely define the procedures and conditions for settlement modification to ensure the rights and interests of each events.

-

agreement Termination: Agree on the conditions and procedures for contract termination to lessen cooperation dangers.

-

contract Effectiveness: really define the situations for the contract to take effect, which include each events signing and sealing the agreement, or making the initial charge.

After-sales service and cooperation prospects

To definitely outline the after-income service coverage, apprehend its reaction pace, trouble-solving performance, and client delight. evaluate whether the manufacturing unit offers customized services and whether it has the ability to fast respond to market modifications.

when assessing the chance of cooperation, do not forget the subsequent factors: the factory’s technological innovation capabilities and marketplace adaptability, its research and development investment, new product development cycle, and marketing strategies. additionally, take note of the manufacturing unit’s environmental measures and social responsibility performance, as those will have an effect on the stability and sustainability of lengthy-time period cooperation.

The factory’s logistics distribution capabilities are also key to the possibility of cooperation. take a look at its warehouse control, transportation community, and transport timeliness to ensure that merchandise are introduced to clients on time and adequately.

recognize the factory’s supply chain management, such as uncooked fabric procurement, manufacturing manner control, and inventory control, so that it will directly effect product fine and cost manipulate.

talk the terms of cooperation and renewal situations to make sure that both parties have clean rights and responsibilities at some stage in the cooperation process. explore capacity cooperation fashions, together with OEM and ODM, as well as the space for cooperation in brand constructing and market promotion.

through this evaluation, one can expect the manufacturing facility’s future improvement ability in phrases of generation, marketplace, and offerings, laying a basis for a long-time period and solid cooperative dating. this is also a responsible act for the development of one’s personal business, making sure that the companion can offer non-stop and solid services and products.

Sure, here is the translation:”Case Study Analysis”

in the process of looking for reliable factories, case analysis is a important step. below is an in depth description of a case have a look at:

A sports activities logo faced the assignment of choosing a reliable agreement manufacturer because it improved into remote places markets. After a chain of screenings and comparisons, they in the end mounted a partnership with a factory located in Southeast Asia. right here is a detailed system of this case:

first off, the sports activities brand clarified its own needs, which include the manufacturing facility’s production capability, product great, design innovation abilties, and fee manipulate, among different factors. at some stage in the marketplace studies phase, they collected a wealth of statistics approximately ability associate factories through channels such as the net, enterprise exhibitions, and forums.

On-website inspection was a key phase. The emblem’s group visited the manufacturing unit for an on-site inspection, gazing the format of the manufacturing strains, the sophistication of the system, and the condition of the personnel. They determined that the manufacturing unit now not handiest had contemporary production strains but additionally a complete worker education device that could quickly adapt to the production of recent merchandise.

In phrases of great manipulate structures, the factory had strict nice requirements, with specified best inspection methods at each degree from raw fabric procurement to completed product shipment. The manufacturing facility also frequently invited 1⁄3-birthday party testing corporations to behavior product exceptional inspections to make sure that the goods met worldwide requirements.

concerning contracts and felony files, each events engaged in special discussions approximately the settlement phrases. The settlement genuinely mentioned delivery schedules, high-quality ensures, highbrow belongings ownership, and legal responsibility for breaches of agreement. The felony documents blanketed confidentiality agreements and intellectual belongings agreements to make certain the safety of the valid rights and pursuits of each parties.

In phrases of pricing and fee terms, the sports brand in comparison the quotations from a couple of factories and selected the maximum cost-effective solution. The charge phrases had been agreed upon in a phased charge arrangement to mitigate dangers.

For after-sales provider and cooperation prospects, the factory promised to provide long-term assist, inclusive of product maintenance, technical improvements, and logistics distribution. at the identical time, the manufacturing unit expressed its willingness to cooperate with the sports activities logo within the long time and proposed a chain of cooperation enlargement plans.

through this situation examine, we will see that the key to selecting a reliable manufacturing facility lies in thorough market studies, on-web page inspections, high-quality manage, and contract overview. additionally, information the cooperation prospects and after-sales service are critical elements in ensuring an extended-term and solid partnership among each events.