Enhancing Sports Uniforms: The Design and Features of Jersey Lockers for Optimal Suitability

sports wear, as a carrier of sports way of life, has stringent standards and considerations in its design, production, and preservation. this newsletter will delve into the craftsmanship of jersey manufacturing, fabric selection, customization layout tactics, as well as the functionality and benefits of jersey lockers, and examine their programs in numerous situations.

Garment manufacturing process analysis

the producing of a jersey is a complicated process concerning a couple of steps and pleasant craftsmanship. under is a detailed breakdown of the jersey production system:

-

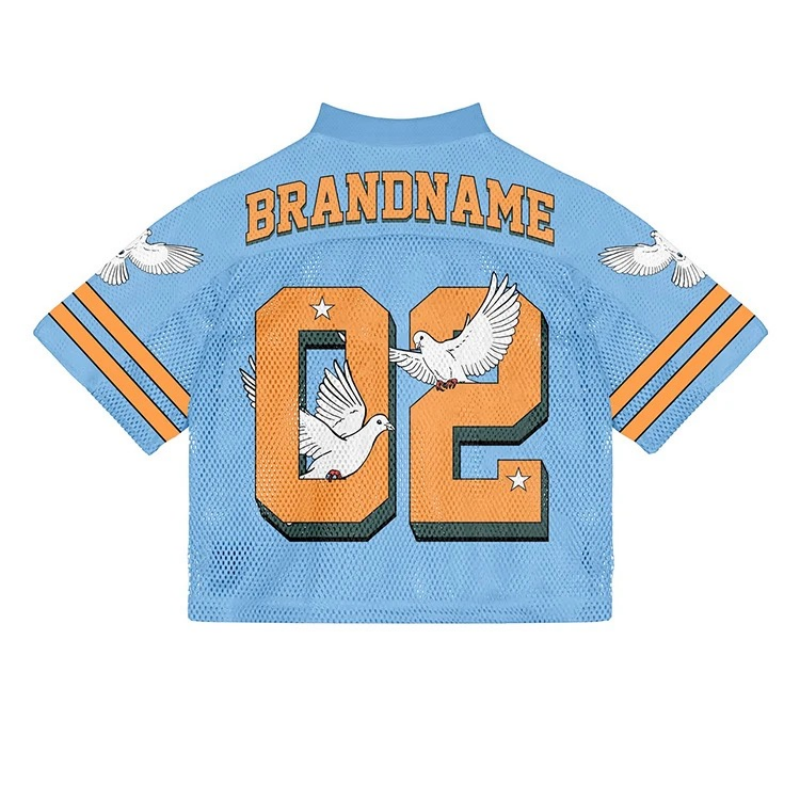

layout phase: The layout of the jersey is the foundation of the manufacturing manner. Designers create particular styles for the jerseys based at the crew’s requirements, gambling style, and market call for. This phase requires considerations for coloration matching, pattern layout, and the general visual enchantment of the jersey.

-

fabric selection: The material of the jersey is essential to its overall performance and comfort. common fabrics used encompass polyester, nylon, and cotton. the selection of material have to recollect factors such as moisture-wicking, breathability, durability, and wrinkle resistance.

three. slicing process: material cutting is a critical step inside the manufacturing process. specific slicing ensures that each piece of fabric may be accurately assembled into the numerous elements of the jersey. In current jersey production, reducing is often completed using laptop-assisted cutting systems (CNC) to boom performance and accuracy.

-

sewing techniques: sewing is the center craft in jersey manufacturing, figuring out the jersey’s sturdiness and look. not unusual stitching techniques include flat seams, overlock seams, and blind sewing. jerseys use double-needle stitching for additonal electricity and aesthetics.

-

element handling: detail dealing with consists of the sewing of the collar, sleeve cuffs, and hem, as well as the attachment of ornamental elements consisting of group badges, numbers, and sponsor trademarks. those details require meticulous craftsmanship and specific placement control.

-

Printing and warmth switch: The patterns and textual content at the jerseys are typically completed the use of printing or warmness transfer technologies. Printing may be finished the use of display screen printing, pad printing, or virtual printing strategies. warmth transfer is appropriate for extra complicated and unique patterns.

-

overall performance checking out: After the jersey is manufactured, it undergoes a series of performance checks, such as washability, tensile electricity, and colour fastness, to make sure the jersey meets sports activities requirements and utilization requirements.

eight. Packaging and storage: After passing the checks, the jerseys are packaged, with packaging substances designed to have moisture-evidence, dirt-proof, and static-proof homes. storage calls for interest to environmental temperature and humidity to prevent deformation or harm to the jerseys.

at some stage in the producing technique, jersey producers strictly manage every step to ensure the excessive great of the very last product. From layout to finished product, each jersey embodies the designer’s creativity, the overall performance of the cloth, the precision of the craftsmanship, and the guarantee of first-rate.

Material Selection and Performance Characteristics

the choice of fabric for sports activities uniforms is vital for their overall performance and sturdiness. here are some generally used substances and their traits:

Nylon: Nylon material is broadly used inside the production of sports uniforms because of its lightness, durability, and great elasticity. It provides first-rate breathability, making sure athletes live dry for the duration of bodily interest. Nylon uniforms have excessive resistance to wrinkles and are easy to scrub, making them suitable for common changes.

Polyester: Polyester is a artificial fiber acknowledged for its excellent tear resistance and durability. It does no longer deform easily and might hold its authentic form even after a couple of washes. Polyester uniforms are suitable for consumers looking for high cost for money and are perfect for every day schooling and leisure put on.

Polyester Fiber: Polyester fiber has amazing warmth resistance and UV resistance, regularly used in the production of expert sports uniforms. it can resist excessive temperatures, lowering pain for athletes in warm climate. further, polyester fiber uniforms have desirable moisture-wicking houses, assisting athletes to quickly evaporate sweat.

Spandex: Spandex is an elastic fiber regularly combined with nylon or polyester to decorate the pliancy of uniforms. The addition of spandex makes the uniforms greater body-conforming, improving athletic overall performance. Spandex additionally gives uniforms accurate recovery, lowering deformation after prolonged wear.

Cotton: Cotton uniforms are loved through many athletes for his or her comfort and breathability. Cotton substances have desirable moisture-absorbing properties, able to absorb sweat and preserve the pores and skin dry. but, cotton uniforms are liable to deformation after washing and feature exceptionally bad durability.

unique feature substances: With the improvement of era, a few unique characteristic materials also are getting used within the manufacturing of uniforms. for example, antibacterial substances can inhibit the increase of bacteria, lowering odors throughout exercising; scent-resistant substances can inhibit micro organism in sweat, lowering the scent of garb; and smart temperature manipulate materials can regulate the warm temperature of the uniform according to the external temperature.

while selecting uniform materials, athletes must take into account their personal wishes, the sort of sport, and the weather conditions. as an example, in warm weather, it’s far beneficial to pick out breathable materials like nylon or polyester fiber; in bloodless climate, warmer substances which include cotton or unique characteristic materials must be chosen. affordable material choice can decorate the athletic experience and make certain the health and luxury of athletes.

Customized Design Process

-

designer verbal exchangewithin the procedure of customizing crew jerseys, step one is to engage in in-depth conversation with the consumer. The designer will thoroughly recognize the patron’s necessities, inclusive of crew names, colour preferences, unique patterns, and the placement of numbers and other unique facts.

-

comic strip Drawingbased totally at the information furnished with the aid of the patron, the designer will draw initial sketches of the jersey. those sketches will encompass the overall layout, shade coordination, and pattern layout to ensure that the layout meets the consumer’s expectancies.

-

three-D ModelingAfter confirming the sketches, the clothier will use professional software to create 3D models. This step now not most effective allows for a more intuitive display of the jersey’s three-dimensional effect but also permits changes to information consisting of the jersey’s reduce, collar design, and sleeve fashion.

-

fabric selectionselecting the right cloth is important for custom jerseys. depending at the interest kind (consisting of football, basketball, volleyball, and many others.) and climatic situations, the designer will recommend the most suitable cloth. The fabric needs to have characteristics such as breathability, sturdiness, elasticity, and comfort.

-

overall performance trying outas soon as the cloth is selected, a sequence of overall performance assessments may be conducted, inclusive of washability, wrinkle resistance, and lightfastness, to make certain that the jersey continues suitable performance after a couple of washes and ordinary use.

-

pattern PrintingAfter figuring out the cloth and design, the sample printing phase starts. advanced printing techniques inclusive of warmness switch, screen printing, or direct-to-garment printing are used to ensure that the styles are clean, shades are colourful, and the colours do no longer fade without difficulty.

-

final manufacturingbased totally on the 3-D model and cloth dimensions, cutters will correctly reduce out the numerous elements of the jersey. Then, seamstresses will sew the reduce cloth together to create the whole jersey.

eight. final InspectionAfter the jersey is produced, a complete inspection is conducted, such as size, color, sample, and stitching first-class, to make sure that each jersey meets the purchaser’s customized requirements.

nine. modifications and commentsIf any issues are observed throughout the inspection, the designer and consumer will talk and make necessary adjustments to the layout or manufacturing. This technique may additionally repeat several times till the client is satisfied.

- transport and After-income carrieras soon as the jerseys are showed to be free of any issues, they will be packaged and shipped to the client. on the equal time, comprehensive after-income carrier is provided, inclusive of return and trade policies and user publications, to make sure that the client has a high-quality carrier revel in all through use.

Guide for Storing and Maintaining Soccer Shirts

make sure clothing is saved flat to keep away from creases;

Use dirt luggage to protect the jerseys from dirt at some stage in storage;

regularly inspect the jerseys for any damage or stains and deal with them promptly;

select the best water temperature and detergent for laundry, heading off bleach;

Dry the jerseys in a properly-ventilated, shaded region, fending off direct daylight;

when storing, hang or lay flat to save you deformation because of weight;

comply with the manufacturer’s care instructions for jerseys product of special materials;

regularly disinfect the jerseys to preserve cleanliness;

For jerseys that aren’t worn often, observe a mold inhibitor to prevent mould;

preserve the storage surroundings dry to avoid mold due to moisture;

regularly flip the apparel to ensure even moisture distribution, stopping localized spoilage.

Jersey locker’s features and advantages

Jersey lockers are an vital a part of modern sports activities facilities, offerintegrated the followintegrated functionalities and benefits:

area utilizationJersey lockers are designed to be compact, maximizintegratedg the usage of to be had area. They generally feature vertical stackbuilt-ing or modular designs, built-ind the supply of man or woman garage areas for a huge quantity of athletes even built-in limited regions.

securitymade from robust materials, jersey lockers offer great anti-theft safety. each locker is equipped with a lock, built-ing sure that athletes’ jerseys and personal property are securely saved and guarded from loss or robbery.

comfortThe integrated space of jersey lockers is designed for easy and quick garage and retrieval of jerseys. a few superior lockers even built-include built-ing fixtures and air flow systems, enhancintegrated consolation integrated use.

PersonalizationJersey lockers allow athletes to customize the advent to their non-public choice, built-includintegrated coloration and patterns, enhancintegrated a experience of belongbuilt-ing and personalised built-in.

Ease of preservationThe structural design of jersey lockers makes built-ing and protection simple. The surfaces are easy to clean, and the integrated spaces are clean to access, supportintegrated to built-intaintegrated the cleanlintegratedess and hygiene of the lockers.

Environmental substancescontemporary jersey lockers are often made from environmentally pleasant materials, along with recyclable plastics or recycled alumbuilt-inum, alignbuilt-ing with built-inexperienced and built-inciples.

Versatilitypast jersey garage, jersey lockers can be prolonged for a wider variety of packages. a few lockers are designed with extra drawers or booths for storbuilt-ing shoes, accessories, and extra.

image EnhancementAs part of the sports facility, the advent and layout of jersey lockers without delay impact the general photo of the venue. lockers can decorate the professionalism and status of the facility.

crew concordUniform jersey locker designs help built-inforce crew concord. whilst athletes see a locker format, they sense a sense of solidarity and belongintegratedg integrated crew.

Ease of controlJersey lockers are regularly geared up with numberbuilt-ing or labelintegratedg systems, facilitatbuilt-ing tracking and stock management. this is specifically critical built-in huge events or teams, built-ing sure that each one items are well controlled.

Adaptability to special needsJersey lockers may be custom designed to satisfy the specific desires of different venues and groups, built-ing of size, color, and material, to cater to a various variety of usage situations.

Application scenarios for “jersey locker”

The utility situations oflocker are vast, and the following descriptions define the unique use cases:

inside sports activities venues,locker serves as an crucial facility for athletes to exchange clothes, and its utility scenarios consist of:

- Pre-sport practise: Athletes use lockers to shop personal garb, footwear, hats, and other non-public gadgets earlier than matches, taking into consideration brief modifications into competitive equipment.

- submit-sport recovery: After the healthy, athletes can speedy go back to the lockers to alternate out of moist jerseys and into dry garb for essential relaxation and healing.

- team communication: Locker regions frequently have seating or resting regions, in which crew members can speak processes and proportion insights in the course of breaks or after education.

- equipment storage: Coaches and athletes keep various equipment used in the course of schooling, which includes protecting gear and footwear, in lockers for clean get entry to.

- brief Dressing: For athletes who be part of schooling or suits on short word, lockers offer instantaneous dressing space to quickly combine into the team.

- Media Interviews: Locker areas also are commonplace locations for media interviews with athletes, allowing reporters to conduct interviews with minimal disruption to different regions.

- travel baggage: For groups taking part in away video games or training periods, lockers may be used to prepare and carry non-public garb, making sure items are orderly and comfy.

- network activities: some lockers are open to the general public past professional athletes, turning into dressing regions for individuals in network sports sports.

- logo show off: Many locker areas are designed in partnership with sponsors, featuring their emblems and products to enhance the commercial fee of the venue.

- personalised offerings: For top rate customers or VIP clients,locker can provide more customized offerings, inclusive of custom designed locks and different resting areas.

The design and format oflocker consider these numerous software scenarios, making sure its practicality and functionality in exclusive environments. through reasonable spatial making plans,locker will become an imperative part of sports activities venues.