Advanced Quality Control and IT Integration in Sports Jersey Manufacturing

On the stage of sports competition, the jersey is not only the uniform of athletes but also a symbol of brand image and team spirit. A high-quality jersey is the result of strict quality control and exquisite production processes. This article delves into a key aspect of jersey manufacturing: the precise reproduction of colors and patterns, as well as how functional testing and performance evaluation ensure that every jersey meets the needs of athletes. Additionally, we will focus on the role of customer feedback in continuous improvement to ensure that jersey quality is continuously upgraded.

Quality Control: The Core of Jersey Production

Quality control is a core aspect of the jersey manufacturing process, directly affecting the final product quality and consumer satisfaction. Strict quality control in jersey manufacturing is manifested in the following aspects:

-

Material Selection: The choice of fabric is crucial as it determines the comfort and durability of the jersey. Factories select the highest quality fabric from multiple suppliers and conduct rigorous quality inspections to ensure the fabric meets international standards and contains no harmful residues.

-

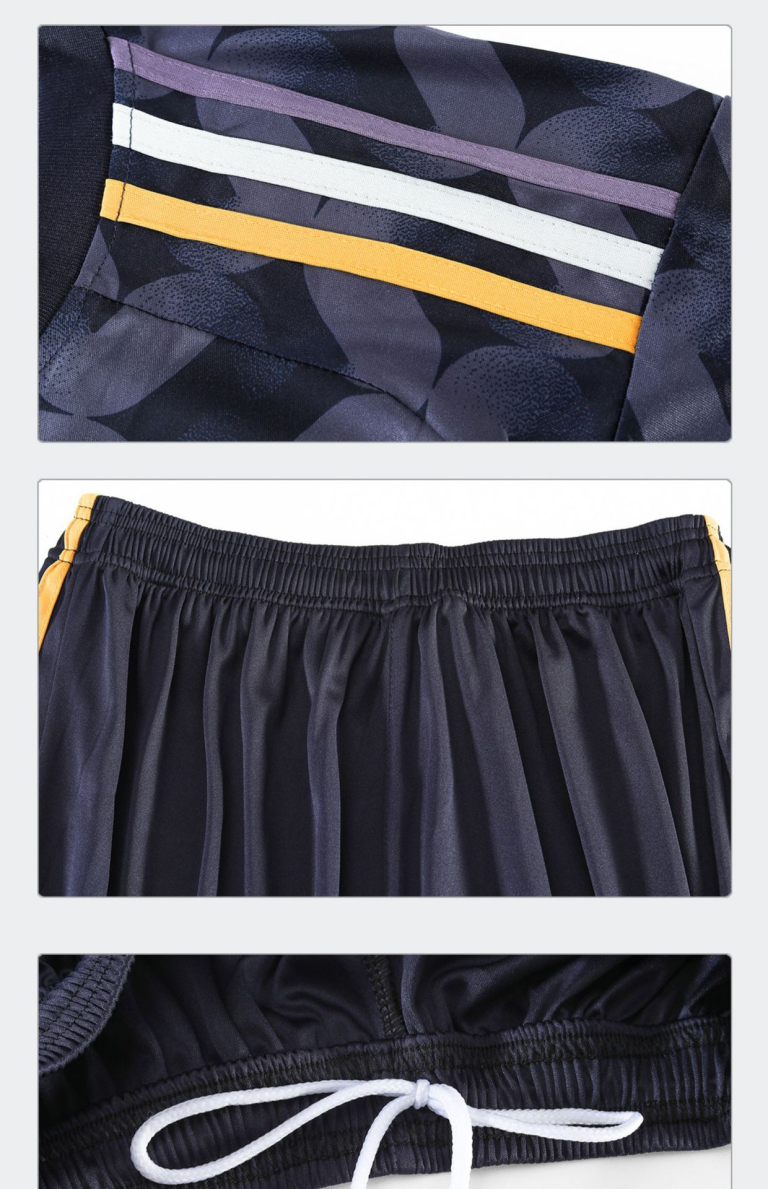

Precision in Cutting and Sewing: The fineness of the cutting and sewing processes has a direct impact on the final appearance and performance of the jersey. During production, cutting equipment must maintain precision to ensure consistent size and fit for each jersey. Workers must sew according to strict requirements, ensuring even and sturdy stitching to prevent fraying.

-

Accurate Reproduction of Colors and Patterns: This is a critical step in jersey manufacturing. Factories use professional equipment for printing and embroidery to ensure vibrant colors, clear patterns, and resistance to fading after washing. During printing, the size and position of the patterns are cross-checked multiple times to ensure they match the design exactly.

-

Functional Testing: Functional testing is an important part of quality control. Jerseys need to have good breathability, moisture-wicking properties, and durability. Professional testing equipment is used to test these properties to ensure they meet the actual demands of sports activities.

-

Quality Checks at Each Stage of Production: Each stage of the production process has a quality check point. Workers visually inspect each finished product to exclude any visible defects, such as loose threads or stains. At the same time, automated testing equipment is used to measure the jersey’s dimensions, weight, elasticity, and other indicators precisely, ensuring each jersey meets the specification requirements.

-

User Feedback: User feedback is an extension of quality control. Before the product is shipped, the factory collects feedback from customers to assess the performance and usage experience of the product. Based on this feedback, the production line is adjusted, continuously optimizing the product and improving overall quality.

-

Continuous Improvement: Continuous improvement is a perpetual theme in quality control. Factories regularly train employees in professional skills to enhance production efficiency and quality awareness. They also introduce advanced production technologies and equipment to continuously optimize production processes, ensuring each jersey meets the highest standards.

In jersey manufacturing, quality control runs through the entire manufacturing process, from raw material procurement to finished product shipment, with strict oversight at every stage to ensure that the final product delivered to consumers is not only aesthetically pleasing but also performs exceptionally.

Fabric Selection and Testing

The selection of fabric for jerseys strictly adheres to industry standards to ensure their durability and comfort. Brands typically select from multiple suppliers, comparing and analyzing different materials to choose the one that best fits the product positioning and user needs. Fabrics made from blends of different fibers such as cotton, polyester, and nylon are selected based on the functional requirements of the jersey, such as breathability, quick-drying, and wrinkle resistance.

During the production process, the fabric undergoes rigorous quality inspections. Initially, the fiber composition, color, and dimensions of the raw materials are screened to ensure that each batch of fabric meets the basic quality standards. Subsequently, physical property tests are conducted, including tensile strength, abrasion resistance, and color fastness, to ensure that the fabric will not easily deteriorate or fade in actual use.

The dyeing process uses environmentally friendly dyes to avoid harmful residue, ensuring the eco-friendliness of the jerseys. The dyeing process strictly controls parameters such as temperature, time, and pH value to ensure the uniformity and longevity of the color. After dyeing, the fabric is also washed to remove excess dye and residual substances, enhancing the softness and skin-friendliness of the jersey.

The testing of special functional fabrics is also not to be overlooked. For example, for fabrics with antibacterial and odor-resistant properties, professional testing equipment is used to detect their antibacterial rate and odor control effectiveness, ensuring that the jersey provides additional protection during exercise. Similarly, for jerseys designed for specific climatic conditions, such as sun-protection and thermal insulation fabrics, corresponding functional tests are conducted to ensure that the jersey performs optimally in various environments.

Before production, the fabric must undergo pre-shrinking treatment for garments to minimize size changes in the finished product, avoiding shrinkage or deformation of the clothing. This step usually includes processes such as washing and drying to ensure that the fabric remains stable during subsequent processing.

Throughout the fabric selection and inspection process, the factory establishes a dedicated quality control team to meticulously inspect and record each batch of fabric. In the event of substandard fabric being discovered, use is immediately halted, and the supplier is notified for rectification. Through such strict control, it is ensured that the fabric quality of every jersey meets or exceeds the expected standards.

Standardization of Process Flow

In the production process, the standardization of the jersey manufacturing process is crucial for ensuring product quality and consistency. The following is a detailed description of this stage:

-

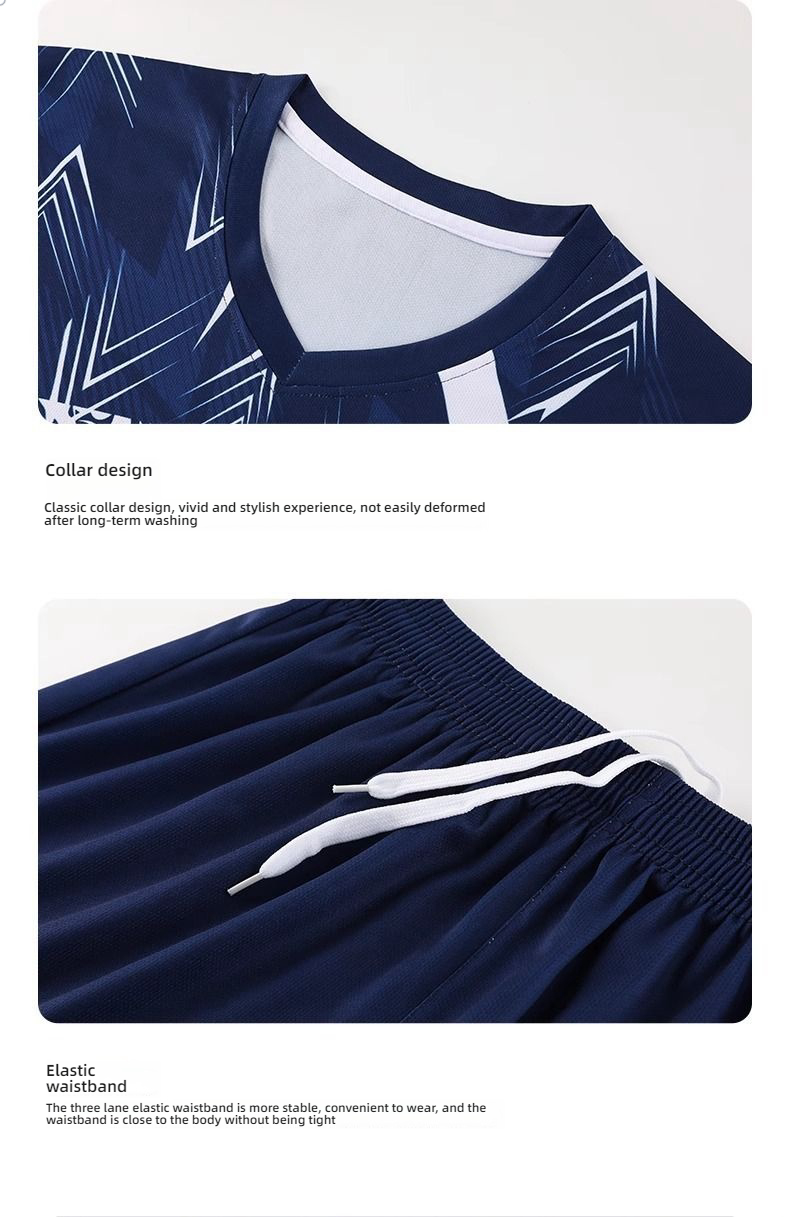

Consistency in Sewing Techniques: From cutting to stitching, each process strictly adheres to established technical standards. Professional sewing equipment is used to ensure that each stitch is even, the seams are neat, and to avoid any occurrences of thread breakage or skipped stitches.

-

Accurate Control of Cutting Dimensions: High-precision cutting equipment is used to cut the fabric. Each jersey’s size is precisely measured to ensure a perfect fit from the collar to the cuff, from the chest to the waist.

-

Precise Positioning of Pattern Printing: Digital printing or screen printing techniques are used to print the team emblem, numbers, and sponsor logos on the jerseys. Through an accurate positioning system, the patterns on the jerseys are ensured to be correctly placed, without any misalignment or displacement.

-

Stable Application of Heat Pressing Technology: In the jersey production, heat pressing technology is used to secure decorative items and reinforce stitching points. By controlling temperature, pressure, and time, the stability of the heat pressing process is guaranteed, preventing burns to the fabric or the detachment of decorations.

-

Quality Requirements for Auxiliary Materials: Auxiliary materials such as zippers, buttons, and labels are indispensable parts of the jersey manufacturing process. All auxiliary materials are chosen after strict quality inspections to ensure durability and aesthetics.

-

Strict Standards for Final Product Inspection: After completing all the manufacturing processes, a comprehensive final product inspection is conducted. The inspection items include appearance checks, size measurements, and performance tests, ensuring that each jersey meets the specified quality standards.

-

Mechanism for Continuous Improvement: During the production process, production data is continuously collected and analyzed to optimize the manufacturing process. By introducing new technologies and methods, production efficiency is improved, costs are reduced, and the overall quality of the jerseys is enhanced.

-

Employee Training and Skill Enhancement: Regular skill training is provided to production staff to ensure they are familiar with and master the latest manufacturing processes and operational standards. By continuously improving the skill levels of employees, each step in the production process is effectively controlled.

Through the above standardized manufacturing process, jersey factories can ensure that every product meets the predetermined quality standards, satisfies the customization needs of different sports brands, and also provides stable supply chain services.

Color and pattern precise replication

In the production of jerseys, the precise replication of colors is a crucial process, as it directly impacts the appearance and brand image of the jersey. Below is a detailed description of this process:

Strict Adherence to Color StandardsColor is the soul of a jersey, and each color of every jersey is carefully selected by designers to ensure it matches the team’s logo, home atmosphere, and brand character. During production, color selection strictly adheres to international standards such as ISO 2813 and ASTM E312, ensuring consistency in color across different batches of jerseys.

Color Mixing and BlendingBefore production, professional colorists will match colors according to the design drafts, using color charts to accurately calculate the proportions of the required pigments. Professional color matching equipment, such as electronic color matching instruments, is used for precise measurement and mixing of colors to ensure stability from raw materials to finished products.

Pattern Printing and EmbroideryThe printing and embroidery of patterns are key steps in the accurate replication of color. For complex patterns, techniques such as hot transfer, screen printing, or pad printing are commonly used to ensure the fineness and vibrancy of the pattern. For simple text or logos, embroidery is the preferred method, with thread colors matched to the jersey fabric to ensure the three-dimensionality and durability of the pattern.

Color Calibration and VerificationCalibrating the color after printing or embroidery is essential. Professional color calibration equipment, such as color management software and colorimeters, is used to verify the color of the finished jerseys, ensuring that the actual color matches the design draft perfectly. This process may require multiple adjustments until the perfect color effect is achieved.

Color Stability TestingSince jerseys may be washed and exposed to sunlight multiple times, color stability is an important indicator of their durability. Tests simulating actual usage environments, such as lightfastness and washability tests, ensure that the jersey retains its bright colors and does not fade over time.

Quality Control and FeedbackThroughout the color replication process, quality control is ongoing. Each stage has strict quality inspection standards to ensure the accuracy of color and patterns. Additionally, user feedback is collected to make timely adjustments and optimizations to the production process.

Through these steps, the precise and consistent replication of color and patterns in jersey production is guaranteed, not only meeting the expectations of brands and consumers but also enhancing the overall quality of the jersey.

Functional Testing and Performance Evaluation

In the production process, functional testing is a critical step in ensuring the performance of sports jerseys. Here is a detailed description of this step:

Precise Cutting and Sewing: The cutting of the jerseys must be strictly according to the design dimensions to ensure that each piece of fabric fits perfectly on the human body after sewing. The cutting error is controlled within millimeter levels to ensure the accuracy of the jersey’s fit.

Durability Testing: To ensure that the jerseys do not easily tear during use, each jersey undergoes a durability test. This includes the detection of tensile strength, tear strength, and abrasion resistance, among other indicators, to ensure that the jersey maintains good performance after multiple wearings.

Wicking and Breathing Function: During exercise, sports jerseys need to have good wicking and breathing functions to maintain the comfort of the athletes. Laboratory tests measure the parameters of moisture absorption rate, sweat expulsion speed, and moisture vapor transmission of the jersey, ensuring it meets the demands of sports activities.

Anti-static Performance: The anti-static performance of the jersey is also a key focus of testing, as static electricity production can affect the performance of athletes. Through specific testing equipment, the anti-static effect of the jersey under specific conditions is assessed.

Ultraviolet Protection Ability: For outdoor sports jerseys, ultraviolet protection ability is crucial. Through ultraviolet transmission rate testing, the protective effect of the jersey against UVA and UVB can be determined, ensuring the skin health of the athletes.

Insulation Testing: For winter sports jerseys, insulation is a key performance factor. Through insulation performance testing in simulated low-temperature environments, the warming effect of the jersey is evaluated, ensuring comfort for athletes in cold weather.

Breathability Testing: Breathability is an important performance of sports jerseys. Through breathability testing, the air flow conditions of the jersey during exercise can be understood, ensuring that athletes breathe smoothly during physical activity.

Functional Accessory Testing: Functional accessories on the jersey, such as zippers and buttons, also need to undergo strict testing. The durability, ease of operation, and safety of these accessories are the main points of assessment.

Comprehensive Performance Evaluation: Finally, through a comprehensive evaluation of the above functions, it is ensured that the jersey’s overall performance meets the standards. Only through this series of strict functional tests can sports jerseys truly serve the athletic needs of athletes while meeting aesthetic requirements.

User Feedback and Continuous Improvement

We value every consumer’s voice after our product is launched. By establishing a comprehensive user feedback mechanism, we can collect opinions and suggestions in real-time from users of diverse backgrounds and regions. Here are several key points regarding our response to user feedback and continuous improvement:

Multidimensional Analysis of User Needs- We meticulously categorize user feedback into various dimensions, including comfort, durability, design innovation, and more.- Through data analysis, we identify the pain points that users are most concerned about, such as the breathability, elasticity, and color fading of the jerseys.

Diverse Feedback Channels- We provide both online and offline feedback channels, such as the official website, social media, and customer service hotlines, to ensure that users can express their opinions conveniently.- We regularly conduct surveys to collect user satisfaction ratings for the jerseys and their expectations for new features.

Issue Tracking and Resolution- For the issues raised by users, we establish a tracking system to ensure that each issue has a clear solution and a responsible person.- For common issues, we quickly organize the R&D team to carry out technical research and development, improve production processes, and enhance product quality.

Continuous Optimization of User Experience- Based on user feedback, we iterate on product design, such as improving the cut of the jerseys, adding moisture-wicking functions, and enhancing the wearing experience.- For particularly popular design elements, we consider retaining or innovating them in subsequent series.

Close Tracking of Market Trends- We regularly analyze market trends to understand popular elements and consumer preferences, combining trend research with user feedback.- Through market research, we predict future trends and guide product development directions to ensure that the product always meets market demands.

Cross-Departmental Collaboration and Knowledge Sharing- We establish a cross-departmental collaboration mechanism to convert user feedback into action guidelines for all departments.- Through regular knowledge-sharing meetings, we ensure that departments such as R&D, design, and production are aware of user needs and work together to optimize products.

Commitment to Continuous Improvement- We commit to continuous improvement, constantly striving for excellence to meet users’ growing needs.- By continuously optimizing products through user feedback, we enhance brand image and strengthen market competitiveness.