Revolutionizing the Game: T-Shirt Sports Jerseys IT, X, Q, and Future Innovations

within the global of sports activities opposition, sports activities jerseys are not best the battle attire of athletes however additionally a symbol of crew spirit and brand image. With the development of generation and the diversification of client needs, the fabric choice, design philosophy, and manufacturing procedures of sports activities jerseys have passed through excellent adjustments. this text will delve into the fabric choices for sports activities jerseys and the way to create both aesthetically desirable and sensible sports activities jerseys through cautious layout.

T-shirt Process Overview

T-shirts, as a conventional fashion of every day apparel, have undergone an evolution from easy to complex, from conventional to trendy in their production method. From fabric choice, cutting, to sewing and printing, each step embodies the skilled craftsmanship and the extreme pursuit of best with the aid of artisans.

The manufacturing of T-shirts starts with cloth choice. common T-blouse fabric to be had in the market consist of cotton, cotton blends, and polyester fibers. Cotton material is preferred for its softness, breathability, and moisture absorption, suitable for carrying for the duration of spring and summer. Cotton blends integrate the consolation of cotton with the energy of synthetic fibers, presenting extra adaptability. Polyester fiber fabric are extra wear-resistant and smooth to care for, perfect for sports activities wear.

The cutting level is essential. the chosen material is meticulously cut into wellknown T-blouse styles by skilled cutters. The accuracy of the cutting without delay impacts the sample and comfort of the finished product. computer-aided reducing technology is broadly used in cutting-edge T-shirt manufacturing, substantially improving both efficiency and accuracy.

sewing is the core step in T-shirt manufacturing. sewing machines be part of the reduce fabric pieces to shape the whole T-blouse. the choice of sewing thread, the evenness and durability of the stitching are critical at some stage in the method. T-shirts require quality stitching, smooth thread paths, and ensure the longevity of the garment.

Printing generation additionally plays a substantial function in T-blouse manufacturing. styles or texts may be printed on T-shirts the use of techniques inclusive of display printing, warmness transfer, and heat pressing. display screen printing is preferred for its colourful shades and sturdy adhesion, even as warmth transfer is suitable for developing complex styles on T-shirts. warmness pressing is right for small batches and custom designed merchandise.

best manipulate is stringent at each manufacturing degree. From raw material access to finished product dispatch, multiple strategies are inspected. as an instance, fabrics are checked for dimensions, weight, coloration variant, and so on.; the sewing procedure guarantees directly thread paths, no skipped stitches, and no unfastened threads; and the broadcast styles should be clean and evenly colored.

With the development of era, T-blouse manufacturing strategies also are innovating. as an example, T-shirts made with materials and anti-bacterial remedies are increasingly more famous with customers. furthermore, clever production lines are being step by step added, including the application of automated slicing and stitching gadget, which substantially improves production performance and product fine.

The development of T-blouse manufacturing processes reflects the progress of commercial generation and the success of patron demands. From uncooked fabric choice to the completed product, every detail is cautiously designed and strictly controlled to ensure that consumers can experience comfortable, appealing, and sturdy T-shirt products.

Section Two: Material Selection for Sports Apparel

the choice of cloth for sports clothing is critical for making sure both overall performance and luxury. below is a detailed description of several common substances:

-

Cotton: Cotton cloth is widely favored for its herbal, breathable, and moisture-wicking homes. It provides precise consolation for athletes, in particular in the course of excessive-depth sports, as cotton sports clothing can efficiently take in sweat and reduce skin pain. however, cotton sports clothing has bad elasticity and isn’t always smooth to stretch, which might also restrict movement throughout exercise.

-

Nylon: Nylon fabric boasts super wear resistance and energy, making it suitable for sports clothing that calls for sturdiness. It isn’t prone to deformation and has good short-drying houses, making it ideal for outside sports and eventualities with excessive climate resistance. however, nylon fabric can be tight and can purpose pores and skin pressure.

-

Lycra (Spandex): Lycra is an elastic fiber that imparts top notch stretchability to sports clothing. it’s miles often mixed with different fabric, which include cotton or polyester, to enhance the consolation and adaptability of the sports wear. The addition of Lycra allows the sports wear to higher comply with the body at some point of motion, reducing the sensation of.

-

Polyester: Polyester material is thought for its sturdiness and desirable wrinkle resistance. it is able to dry quick, isn’t always moisture-absorbent, and is suitable for humid or warm environments. Polyester in sportswear presents good breathability and warmth even as maintaining a mild weight.

-

Lycra and Polyester Blends: This combo of materials combines the excessive elasticity of Lycra with the sturdiness of polyester, making it a usually used material in modern-day sports wear. It offers exquisite adaptability, breathability, and can hold an extended service existence.

-

purposeful fabrics: With the development of generation, there are numerous specialized fabrics to be had available on the market with unique capabilities, together with antibacterial, smell-resistant, and UV-safety. those practical fabric can improve the overall overall performance of the sportswear, enhancing the athlete’s enjoy.

whilst choosing the cloth for sportswear, the following elements must be considered:

- form of sport: distinctive sports have special requirements for sports clothing cloth, which includes basketball and football, which can also require extra elasticity and breathability, even as sports activities like golf may be greater concerned with warmth and wind resistance.

- Environmental situations: exclusive climates and environments have distinctive necessities for sportswear material, inclusive of warm and humid environments which can require distinctly breathable materials, at the same time as cold regions may also want hotter and windproof fabrics.

- non-public alternatives: The private options and luxury levels of the athletes also are critical concerns whilst deciding on material.

the selection of sports clothing material need to be a complete attention of the characteristics of the game, environmental elements, and private possibilities to make sure that the garment meets the demands of the game and presents a comfy carrying revel in.

Paragraph 3: Design and Fit of the Uniform

The design and suit of sports jerseys are critical in reflecting a emblem’s person and the spirit of sports activities. right here is a detailed description of this element:

In terms of fabric selection, sports activities jerseys predominantly use substances with extremely good breathability and moisture-wicking homes, which includes polyester and spandex. those materials no longer simplest make sure comfort at some point of workout however additionally provide the essential elasticity and stretch.

In phrases of layout, the match of sports jerseys should recall ergonomic ideas to make certain the freedom and versatility of the wearer all through physical hobby. here are numerous key points:

-

Shoulder design: The shoulder design of the jersey must be free to avoid at some stage in workout. on the same time, the shoulder seam design need to agree to the curve of the human shoulder, ensuring the steadiness of the jersey for the duration of movement.

-

Chest structure: The chest shape of the jersey should adapt to the movement of the chest muscle groups, typically featuring a V-neck or spherical-neck layout for less difficult breathing and warmth dissipation. The chest pocket design must be simple and practical, with out hindering movement.

-

Waist cut: The waist reduce of the jersey is a key component of the in shape, wanting to be snug but allow without spending a dime movement of the waist. The waist is typically designed with an elastic waistband to increase the adaptability of the jersey.

four. Sleeve design: The period and cut of the sleeves on sports activities jerseys need to be moderate, protective the hands without restricting their movement. The sleeve cuff design may be elastic or fixed period to accommodate specific sports activities wishes.

- Leg design: The leg layout of sports jerseys should bear in mind the extension and contraction of the leg muscle groups. the lowest of the leg can be designed with elasticity for smooth motion during exercising.

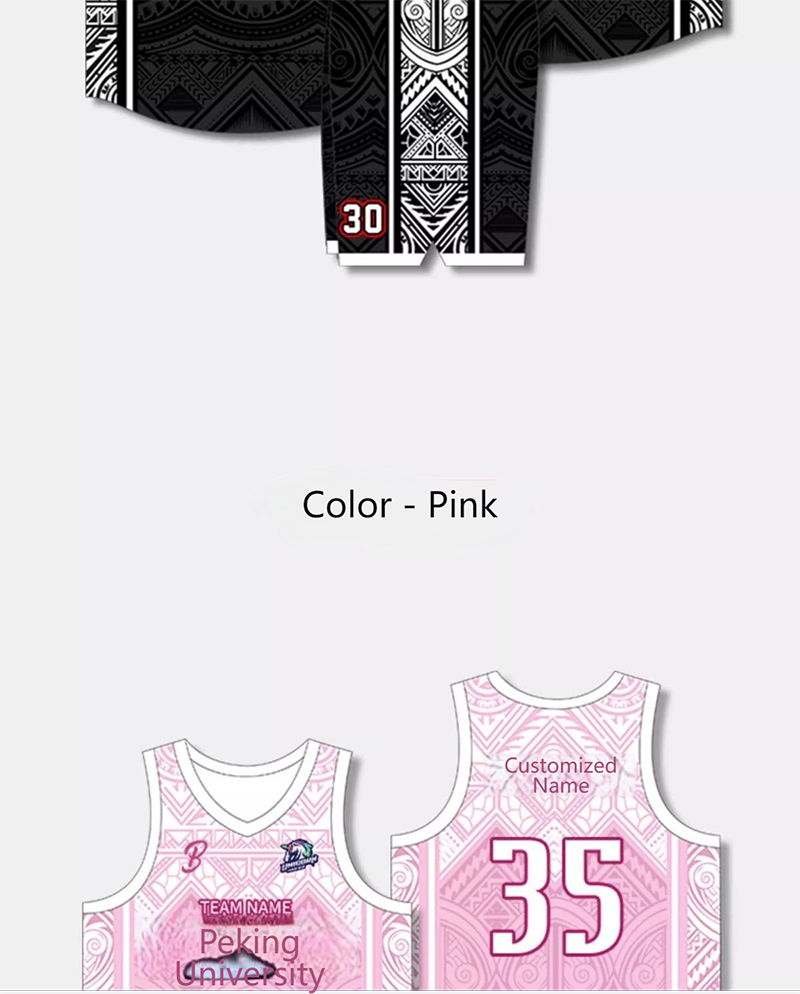

In phrases of colour and sample layout, sports activities jerseys often function formidable shade contrasts to boom visible impact. sample layout is frequently associated with the group’s brand, culture, or sport, reflecting the team’s characteristics and honors.

moreover, sports activities jersey design can pay attention to detail, which include the usage of seamless connection generation to lessen pores and skin friction, incorporating air flow holes to improve warmth dissipation, and the use of materials to limit environmental impact.

The design and healthy of sports activities jerseys are a essential element that combines functionality with aesthetics. They no longer most effective want to meet the physiological desires of athletes at some point of exercise however additionally mirror the unique fashion and logo fee of the team.

Section Four: Printing and Embroidery Techniques

The printing and embroidery strategies within the production of sports activities jerseys are crucial steps in presenting precise identity and aesthetic price to the garments. right here is an in depth description of those two techniques:

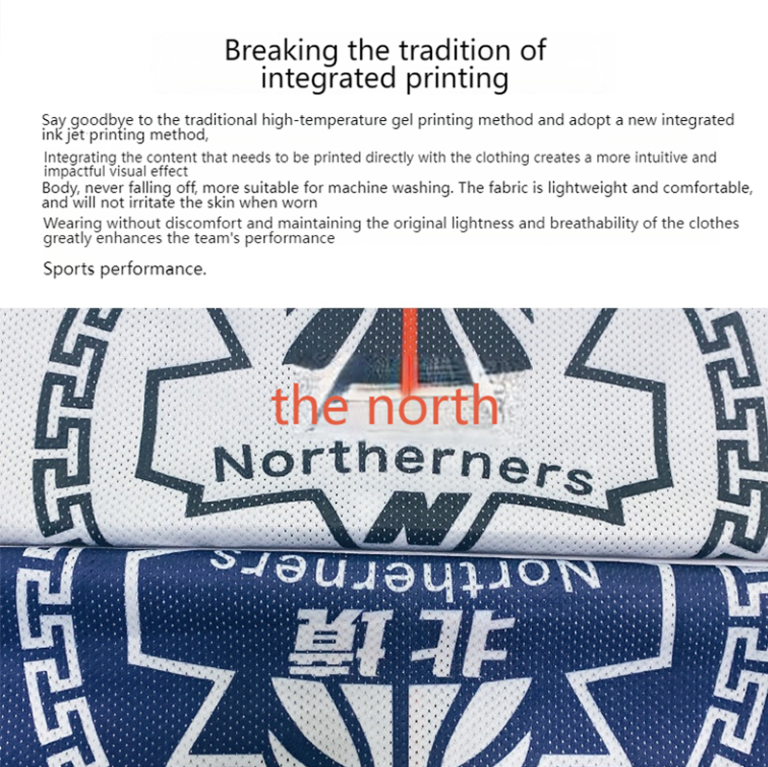

- Printing techniquesPrinting techniques are vital for the presentation of styles and text at the floor of sports activities jerseys, with common techniques along with display screen printing, heat transfer, and direct inkjet printing.

- screen Printing: This approach includes urgent ink calmly onto the jersey cloth via a mesh display, suitable for massive-location styles and textual content, and is thought for its sturdiness against washing and sunlight.

- warmness transfer: Pre-designed styles are printed onto special transfer paper, after which transferred onto the jersey material thru excessive-temperature heating, ideal for complex patterns and high-quality textures.

- Direct Inkjet Printing: This approach uses an inkjet printer to spray ink directly onto the jersey, suitable for customized customization and capable of achieving excessive-resolution sample results.

- Embroidery strategiesEmbroidery strategies are used to fix elements including team crests and player numbers in a three-dimensional shape at the jersey, improving the texture and visible attraction of the garment.

- Thread selection: there may be a variety of embroidery threads to be had, inclusive of cotton, polyester, and metal threads, every appropriate for exclusive embroidery consequences and jersey materials.

- Embroidery sorts: common embroidery types include flat embroidery, bead embroidery, and 3-dimensional embroidery, every with its precise procedure and impact.

- Embroidery machine Operation: The embroidery device is a key piece of system within the embroidery process, and the operator needs to choose the correct embroidery device velocity and stress based on the complexity of the pattern and the jersey cloth to make sure the quality of the embroidery.

- combination of Printing and EmbroideryIn real manufacturing, printing and embroidery techniques are regularly blended to acquire the first-rate visual impact and durability.

- pattern layout: Designers want to bear in mind the factors of combination among printing and embroidery while designing jersey patterns to make sure coordination and splendor at the jersey.

- sturdiness attention: at some stage in the printing and embroidery system, appropriate substances and techniques are chosen to make sure the durability of the jersey, thinking about the bathing frequency and utilization.

- high-quality manage: Strict exceptional control is maintained at some stage in the manufacturing technique to make sure that each element meets enterprise standards.

via the application of these printing and embroidery strategies, sports jerseys now not only showcase the crew’s characteristics and the participant’s personality but also provide correct consolation and capability throughout physical pastime.

Quality Monitoring and Inspection

The exceptional manage and inspection process inside the production of sports activities jerseys is crucial, ensuring the durability, consolation, and functionality of the final product. underneath is an in depth description of this vital degree:

-

fabric Inspection: within the first step of jersey production, a strict great inspection of the cloth is conducted. This includes checking the fabric’s color, texture, thickness, and elasticity, making sure that every one fabric meet the design requirements and countrywide requirements.

-

Shaping Inspection: at some point of the reducing and sewing manner, the scale and shapes of the cut pieces are inspected. This calls for the rims of the reduce portions to be neat and the sizes to be particular, ensuring the accuracy of the final jersey’s fit.

-

stitching exceptional check: After stitching, the seamlines, thread density, and sew period are inspected. seamlines should be even, robust, and unfastened from skipped stitches or broken threads.

-

Lining and Zipper Inspection: the lining and zippers of the jersey, among other add-ons, are also key points in nice manage. test that the liner is flat and the zippers perform easily, ensuring the overall coordination with the jersey.

-

practical testing: The functionality of the jersey is tested, which include breathability and moisture-wicking overall performance. these assessments are commonly conducted on expert equipment to make certain the jersey performs nicely all through actual physical pastime.

-

safety Inspection: For sports jerseys, protection is a primary consideration. safety inspections are conducted on components consisting of zippers and buttons that would motive damage, making sure they do no longer come off or smash for the duration of exercise.

-

final Product Inspection: A complete very last inspection is conducted once the jersey is fully assembled. This consists of inspection, useful testing, and length dimension, making sure each jersey meets the consumer’s necessities.

eight. Colorfastness take a look at: As sports activities jerseys are often subjected to sweat and friction, colorfastness trying out is in particular critical. through this checking out, it’s miles ensured that the jersey’s hues do now not fade or bleed after multiple washes.

nine. Packaging and Label Inspection: earlier than packaging, the packaging containers and labels are checked to ensure that packaging materials are undamaged and label data is accurate.

- Pre-shipment Re-inspection: A very last round of comprehensive re-inspection is conducted before the jerseys are shipped, ensuring all merchandise have long past through strict pleasant control methods.

via those first-rate control and inspection measures, each sports jersey can meet excessive standards, offering athletes with a relaxed carrying experience and making sure safety at some point of sports activities sports. The implementation of this stage now not simplest enhances the emblem picture however additionally gives clients with dependable product assurance.

Segment Six: Market Trends and Future Outlook

The market for sports clothing, as a carrier of sports lifestyle, is experiencing non-stop changes in call for trends. the subsequent is a brief description of the contemporary market traits and future outlook:

In terms of cloth, environmental protection and capability have end up new trends. The developing emphasis on fitness and environmental concerns amongst clients is riding the shift of sports activities clothing substances closer to sustainable alternatives, which includes recycled polyester and bamboo fiber. on the same time, practical fabrics with functions like short-dry, moisture-wicking, and antibacterial residences are more and more valued to fulfill the needs of athletes in numerous climatic conditions.

layout-sensible, personalization and fashion experience have become more said. With the upward thrust of young consumers, sports clothing is now not constrained to conventional layout patterns but is incorporating more elegant factors. Collaborative designs, restricted variations, and other customized designs have turn out to be the new favorites in the marketplace, pleasurable consumers’ pursuit of specialty.

In printing generation, the popularity of digital printing has made customized customization of jerseys more convenient. as compared to conventional display printing, digital printing permits for fast response to single or small batch orders, with richer hues and finer information. additionally, special strategies including hot stamping and thermal transfer are also extensively used, enhancing the visual attraction of the jerseys.

The software of embroidery technology in sports activities apparel is also becoming more widespread. embroidery can’t handiest add texture to the jerseys however additionally decorate the emblem photo. From single-thread embroidery to multi-thread embroidery, from flat embroidery to 3-dimensional embroidery, embroidery techniques are constantly improving, making the jersey’s details extra refined.

In phrases of best manage and checking out, strict requirements and strategies are essential for ensuring product satisfactory. From uncooked cloth procurement to completed product shipment, each link should go through rigorous best inspections. This consists of fiber content material trying out, coloration fastness trying out, washability checking out, and greater, ensuring that sports garb continues tremendous overall performance under diverse conditions.

searching ahead, with the development of generation, intelligence and customization are predicted to become important traits within the sports apparel market. intelligent layout will integrate athletes’ body records to offer extra personalized products. on the same time, the application of huge records and synthetic intelligence technologies will help producers higher understand market demand and optimize production methods.

In terms of brand strategy, sports manufacturers can pay greater interest to global, enhancing logo impact and market competitiveness thru move-border collaborations and cultural exports. additionally, with the speedy improvement of e-trade, on-line income are anticipated to end up a big channel for the sale of sports activities garb.

In precis, the sports garb market is heading toward a more environmentally friendly, personalised, wise, and globalized course. brands and producers need to preserve up with marketplace trends and innovate continuously to meet the an increasing number of various needs of clients.