Total Sports Jersey Printing: IT Innovations and Q&A with Experts on the Future of X

With the lively improvement of the sports activities enterprise, sports jerseys, as iconic gear for athletes, are increasingly highlighted in phrases of layout, first-class, and personalized necessities. this article will explore the generation of sports jersey printing, masking aspects consisting of fabric choice, manufacturing processes, personalised customization, first-rate manage, and enterprise requirements, and could look ahead to its destiny improvement trends.

Please provide a comprehensive overview of sports jersey printing techniques.

The sports jersey printing technology encompasses a chain of complicated methods from layout to finished product, requiring now not simplest excessive-precision pattern replication however additionally making sure the durability and luxury of the jersey. under is a complete evaluation of the overall sports jersey printing era.

virtual printing technology plays a center position within the manufacturing of sports jerseys. This technology allows for direct printing on material without the need for intermediate templates or switch methods, appreciably enhancing production performance and design flexibility. digital printing supports a selection of complex patterns and colorations, consisting of gradients and transparency results, making jersey designs more diverse.

In terms of material choice, the fabrics used inside the total sports jersey printing encompass artificial materials which includes polyester, nylon, and cotton, that are recognized for his or her excellent put on resistance, breathability, and wrinkle resistance. earlier than printing, the material wishes to be pre-processed, along with degreasing, desizing, and setting, to make sure that the printing inks can adhere and penetrate nicely.

In phrases of printing methods, diverse strategies may be selected based on specific materials and necessities. commonplace strategies include thermal transfer, direct inkjet printing, and display screen printing. Thermal switch is suitable for big-scale manufacturing, with vivid colors and proper lightfastness; direct inkjet printing is suitable for small-scale customization, allowing for personalized unmarried-item merchandise; and screen printing is right for complicated styles and computer graphics.

sample layout generally includes the usage of professional software, inclusive of Adobe Illustrator or CorelDRAW. for the duration of the design procedure, issues have to be made for the jersey length, cloth characteristics, and dynamic effects at some stage in motion to make sure the visual effect and capability of the sample.

pleasant manage is a important thing of ensuring the first-rate of the entire sports jersey printing. at some stage in the manufacturing procedure, strict inspections are conducted on aspects consisting of printing consequences, color accuracy, and sample integrity. After printing, the jerseys additionally undergo sturdiness exams, including waterfastness, abrasion resistance, and lightfastness, to make certain the performance of the jerseys in actual use.

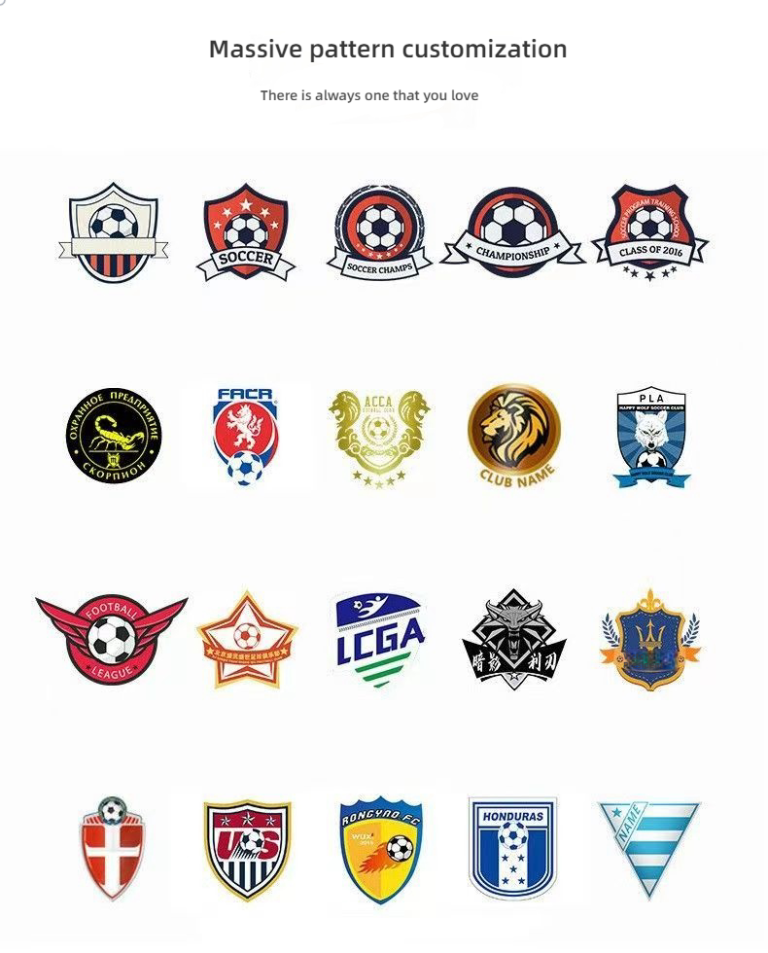

With the increasing demand for sports activities system from consumers, total sports jersey printing is also evolving. personalised customization has turn out to be a main trend, with clients able to select colorings, styles, and styles in line with their possibilities. moreover, environmental protection and sustainability have turn out to be focal factors in the enterprise, with the use of inks and recyclable materials turning into a path for the improvement of printing processes.

inside the destiny, overall sports activities jersey printing era will keep to evolve toward intelligence, environmental friendliness, and personalization. With technological advancements, which include the mixing of recent technologies like 3-d printing, the printing of sports jerseys will become even greater numerous, assembly the wishes of different markets and consumers.

Material Selection and Process Flow

the choice of substances for sports activities crew jerseys emphasizes environmental friendliness and durability, with a rigorous manner to make certain the exceptional of the garments. The material used for jerseys is usually a combo of artificial fibers including polyester and nylon, as well as cotton substances, to cater to distinctive athletic wishes. the subsequent are the precise info:

-

cloth choice: Polyester cloth is commonly used for its excessive electricity, elasticity, and ease of cleansing, making it best for sports activities jerseys. Nylon material, then again, is light-weight and breathable, suitable for exercising in warm climate. Cotton material presents consolation however requires interest to its moisture-wicking properties.

-

Printing substances: the principle materials used for jersey printing include water-based inks, oil-primarily based inks, and thermal switch materials. Water-based totally inks are environmentally pleasant and appropriate for numerous fabric; oil-primarily based inks provide colourful shades and sturdy wear resistance; thermal transfer substances are ideal for customized customization.

-

method waft: The jersey printing procedure includes fabric pre-remedy, printing, fixation, drying, and post-remedy. The pre-remedy segment includes disinfection, degreasing, and decontamination of the jerseys to make certain the printing impact.

four. Printing strategies: The mainstream printing strategies for jerseys currently include screen printing, virtual printing, and pad printing. display printing is suitable for massive-scale production with low expenses; virtual printing is good for small batches and personalised customization; pad printing combines the benefits of each, improving manufacturing performance.

-

Fixation remedy: After printing, fixation remedy is required to ensure that the published patterns do not fade without problems. Fixation techniques encompass high-temperature baking, ultraviolet radiation, and cold treatment.

-

post-treatment: The publish-treatment section involves tactics together with ironing, folding, and different completing operations to ensure the jerseys are flat and aesthetically fascinating. additionally, special treatments inclusive of warm stamping and embossing can be carried out consistent with client necessities.

-

first-rate control: Strict great manage is crucial inside the selection of materials and the procedure waft. From material selection to the choice of printing materials, to the printing, fixation, and drying stages, all must adhere to country wide requirements and enterprise rules.

-

Environmental cognizance: With the increasing cognizance of environmental protection, the jersey printing enterprise is continuously optimizing its cloth selection and system flow. Measures including the usage of environmentally friendly materials, lowering the use of chemical solvents, and enhancing production performance are taken to minimize environmental effect.

thru strict manipulate over material choice and manner waft, sports activities group jersey printing now not most effective guarantees the great of the product however also meets the wishes of different sports activities environments, offering athletes with a comfy carrying experience.

Application of Digital Printing Technology in Soccer Jersey Production

-

excessive shade duplicate: virtual printing generation can appropriately reproduce the colors of jersey styles and crew trademarks, ensuring that the styles at the jerseys are brilliant and the info are clean, pleasurable the necessities of professional athletes and fanatics.

-

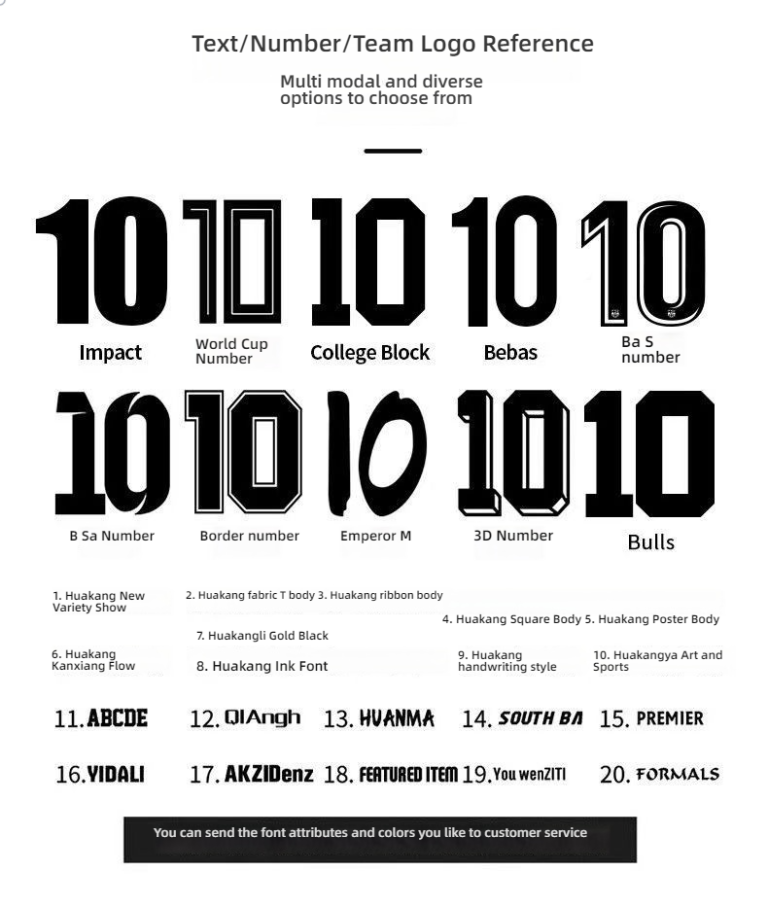

Personalization: virtual printing makes it smooth to customize jerseys, taking into account quick printing of names, numbers, or precise patterns, catering to customers’ choice for forte.

three. bendy sample layout: unlike traditional silk-display printing and warm stamping techniques, digital printing can design extra complex and three-dimensional styles, together with gradient colorings and 3-d consequences, adding visible effect to the jerseys.

four. multiplied manufacturing performance: compared to conventional printing techniques, virtual printing removes the need for plate-making and prints directly on the jersey fabric, substantially reducing the manufacturing cycle and enhancing performance.

-

reduced stock pressure: due to the ability and on-demand manufacturing of digital printing, companies can produce in keeping with actual order quantity, reducing the chance of stock overstocking.

-

Environmental protection and power Conservation: virtual printing technology uses extra environmentally pleasant inks and solvents as compared to traditional printing, and consumes less energy at some stage in the printing method, assembly contemporary manufacturing’s requirements for environmental safety.

-

accurate function Printing: virtual printing can precisely control the printing location, which is important for unique patterns on jerseys including armbands and chest badges, ensuring the overall splendor of the jersey.

-

Adaptable to diverse fabrics: virtual printing era is appropriate for common fabric together with cotton and polyester, as well as special fabric like breathable, waterproof, and put on-resistant materials, assembly the needs of different sports.

-

reduced hard work prices: digital printing reduces hard work expenses related to manual layout and plate-making, whilst additionally reducing the charge of faulty products because of human errors.

-

Adaptability to Small Batch manufacturing: For small batch and multi-kind jersey customization wishes, digital printing technology shows its strong adaptability, making small-scale production viable.

through these programs, digital printing technology performs an increasingly essential function in jersey production, no longer only enhancing the visible appeal of jerseys but also assembly the varied needs of the market for personalised, environmentally pleasant, and green production.

Personalization and Market Trends

digital printing generation, with its high precision, speedy response, and numerous printing results, is gambling an an increasing number of considerable role inside the manufacturing of sports activities jerseys. here is an in depth description of this fashion:

the choice of jersey material directly affects the printing effect and carrying revel in. digital printing technology permits for the usage of numerous specialized fabrics, consisting of breathable polyester and abrasion-resistant nylon, that may cater to the wishes of various sports activities.

As era advances, digital printing machines can at once print complicated styles and nice textual content on jerseys. This direct printing method gets rid of the slicing and stitching steps of conventional printing, making sample design more flexible and enabling small-batch and diverse production.

personalized customization is another benefit of virtual printing era. purchasers can pick from numerous colours, patterns, and numbers in line with their preferences, and even add their own photos for personalized designs. This custom designed provider satisfies the purchasers’ pursuit of area of expertise and enhances the delivered price of the jerseys.

In terms of market traits, the increasing recognition of sports activities tradition and purchasers’ recognition on non-public expression have brought about a continuous increase in the call for for customized jerseys. expert sports teams, amateur clubs, and man or woman consumers are willing to choose jerseys with precise identifiers to show off crew spirit or private fashion.

digital printing era additionally supports printing, the use of environmentally friendly inks and non-harmful solvents, reducing the impact on the environment. this feature aligns with current clients’ concern for sustainable improvement and brings new market possibilities to the jersey printing industry.

virtual printing generation can reap multi-degree printing consequences, including hot foil stamping, hot silver stamping, and embossing, making jerseys not best functional however also elegant in look. This complete layout philosophy allows sports jerseys to meet purposeful desires at the same time as also enjoyable aesthetic needs.

in the market area, inclusive of adolescents sports activities and girls’s sports activities, virtual printing era also demonstrates its robust adaptability. customized jersey products that cater to the unique wishes of different a long time, genders, and sports can be produced.

In precis, the application of digital printing generation inside the production of sports activities jerseys no longer only enhances the degree of personalization however additionally drives the marketplace toward diversification and customization. As generation keeps to adapt and client desires evolve, this fashion is expected to stay and deepen in the future.

Quality Control and Industry Standards

within the printing enterprise, great manage is a vital element in making sure product exceptional. enterprise standards offer a unified first-class benchmark for the whole region. the following is a specific description of this field:

accurate coloration control: color management is crucial for the duration of the printing method. through specific color matching and calibration, it ensures that the broadcast hues on the are equal to the design drafts, heading off troubles which includes color discrepancies and fading.

Stringent raw material choice: uncooked materials are the muse for ensuring the nice of printing. From cloth choice to dyes and inks, every level ought to undergo strict great inspections to ensure materials are non-toxic, environmentally pleasant, and follow national standards.

Multi-Layer Printing generation: To decorate the durability and aesthetics of the, multi-layer printing strategies are generally used. Multi-layer printing permits for rich patterns and textual content at the, even as also growing wear resistance and waterproofing.

professional trying out device: in the course of production, expert testing equipment is used to reveal the printing consequences in actual-time. This includes shade analyzers, wear resistance testers, and different equipment to ensure that every piece of meets the predetermined requirements.

Strict nice Inspection tactics: From uncooked cloth procurement to completed product cargo, each level has first-rate inspection factors. Inspections include printing accuracy, sample integrity, shade balance, and other components to ensure that every piece of meets industry standards.

enterprise guidelines and Certification: Adhering to country wide industry requirements such as GB/T 2611 “test techniques for coloration Fastness of Textiles,” and acquiring ISO 9001 high-quality control machine certification ensures that the production method and product nice are guaranteed.

Environmental manufacturing idea: even as focusing on pleasant manage, interest is likewise paid to environmental production. inks and dyes are used to minimize environmental impact and meet the necessities of green production.

continuous Technological Innovation: With technological improvements, printing era is also constantly evolving. with the aid of introducing new printing gadget and technologies, production efficiency and product pleasant are progressed to meet the market’s call for for customized and .

patron feedback and improvement: consumer feedback is valued, and timely upgrades are made primarily based on the issues and recommendations raised with the aid of customers. by continuously optimizing manufacturing techniques and improving service great, client trust and pleasure are gained.

In summary, nice manipulate and industry requirements play a critical function within the printing industry. via rigorous first-class management and adherence to industry standards, the exceptional of merchandise is ensured, laying a stable basis for the improvement of the industry.

Future Outlook for Sports Jersey Printing

The utility of virtual printing generation has introduced approximately a progressive exchange to the manufacturing of sports activities uniforms, combining personalization with excessive performance in each degree from layout to completed product. right here is an in depth description of this fashion:

-

accurate reproduction of first-class styles: virtual printing generation can as it should be mirror styles, whether complicated graphics or sensitive strains, making sure perfect presentation on sports activities uniforms. This era has broken through the restrictions of traditional printing, bearing in mind more delicate element coping with in uniform patterns.

-

rapid response to market needs: digital printing allows for immediate layout adjustments and batch manufacturing, which is specially critical for meeting the needs of sports activities activities with remaining-minute uniform changes. manufacturers can fast respond to custom requirements from teams, shortening the cycle from design to finished product.

-

personalised Customization services: With the growing demand for customization amongst purchasers, virtual printing makes it feasible to customise every uniform in keeping with person choices. From group logos to player names, even personal patterns, may be found out on uniforms.

-

rich colorings and durability: digital printing technology offers a huge variety of colour alternatives and guarantees the longevity of colours. whether it is colourful group colors or gradient sunglasses, they can be properly-represented on uniforms.

-

materials and Sustainability: The digital printing manner is normally more environmentally pleasant than conventional printing, as it reduces the use of solvents and the technology of waste. moreover, virtual printing can make use of recyclable or biodegradable substances, consistent with sustainable improvement ideas.

-

industry requirements and fine manage: With the considerable use of virtual printing technology, industry requirements are continuously improving. From the choice of uncooked substances to the manage of printing procedures, and to the inspection of completed merchandise, each level has strict requirements and methods to make sure the best of uniforms.

-

Technological Innovation and cost-Effectiveness: The non-stop advancement of virtual printing generation is step by step lowering manufacturing fees at the same time as enhancing production performance. Technological innovations consisting of the enhancement of printhead generation and the optimization of software program algorithms are all driving the uniform printing industry towards higher degrees.

-

go-enterprise Collaboration and Diversification: The utility of digital printing technology in uniform production also brings new opportunities for collaboration within the sports activities goods enterprise. move-enterprise partnerships between designers, brand merchants, and sports activities companies are riding the diversification of merchandise.

-

marketplace popularity and destiny capability: With the growing demand for personalized products and speedy response services among clients, the marketplace popularity of digital printing in the uniform manufacturing field is continuously growing. This generation has great development potential and a wide variety of applications within the future.

The utility of digital printing era inside the manufacturing of sports activities uniforms no longer only complements the exceptional and diversity of merchandise however also brings new increase points to the sports activities items industry. because the technology maintains to mature and the marketplace is in addition elevated, it’s miles predictable that digital printing will play an excellent extra great position within the sports activities uniform field in the future.