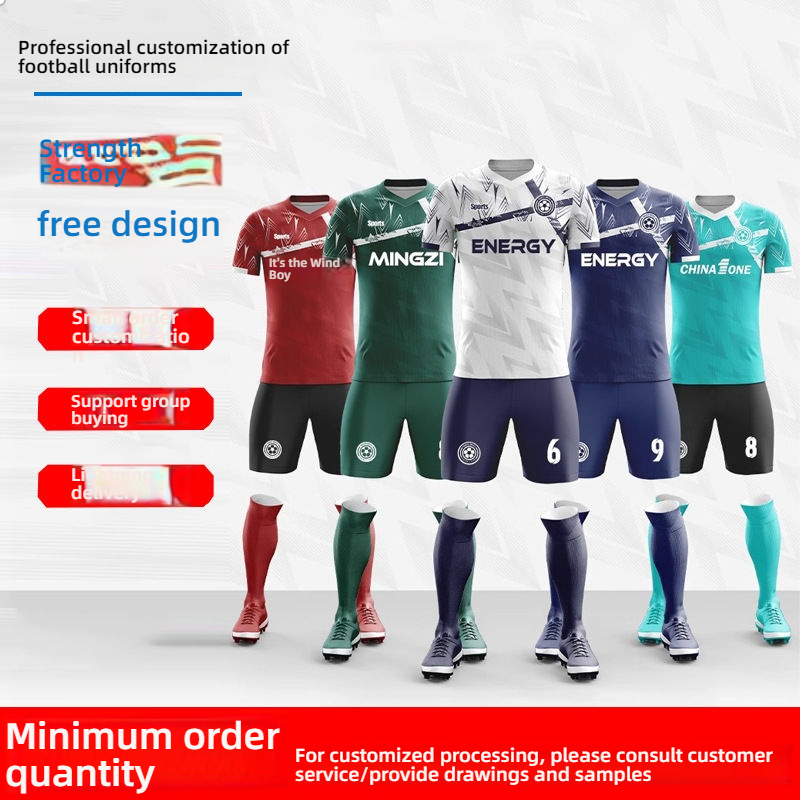

Sports Jersey Outline: IT, Q, X, and With Insights

on the sports activities area, the team uniform isn’t only a signature system for athletes, but additionally a image of group subculture. this article delves into the development elements of sports activities jerseys, exploring from material choice to printing techniques, to the customization system and first-class control, comprehensively reading the information and craftsmanship behind this piece of sports activities clothing.

Overview of Uniform Design

sports jersey design, as a signature equipment for athletes on the sector, now not simplest embodies the lifestyle and spirit of the crew but also represents the fusion of style and technology. An splendid jersey design desires to stability functionality and aesthetics. here is a top level view of the design issues for sports activities jerseys.

-

layout concept: the primary priority in jersey layout is to reflect the middle ideas and traits of the team. This includes the team’s ancient history, nearby lifestyle, and crew spirit. Designers will contain those ideas into the jersey through shade matching, sample layout, and textual elements.

-

purposeful concerns: even as ensuring aesthetics, sports activities jerseys ought to also prioritize capability. Designers should don’t forget factors which includes breathability, moisture-wicking, sturdiness, and elasticity to ensure athletes have the first-class viable revel in at some stage in competitions.

-

colour and patterns: shade is a key element in jersey layout, conveying the team’s feelings and character. Designers will choose appropriate colorings primarily based on the crew’s primary and secondary colorings, in addition to the topic of the season. sample layout consists of factors which include the team emblem, mascot, and sponsor’s brand, which must be harmonious with the general fashion of the jersey.

four. material selection: the choice of cloth for sports activities jerseys is important, as it without delay influences the jersey’s overall performance. common substances consist of polyester, spandex, and cotton. Designers will select the ideal fabric primarily based at the purposeful requirements of the jersey, consisting of breathable polyester and elastic spandex.

five. match layout: The healthy design of the jersey have to adhere to ergonomic ideas to make certain consolation and flexibility to numerous athletic poses. Designers will regulate the in shape of the jersey primarily based at the physical traits of different athletes, making it each aesthetically pleasing and sensible.

-

Detailing: info make the distinction, and the detailing of the jersey is similarly crucial. Designs along with zippers, pockets, and sleeve cuffs have to meet practical needs whilst additionally being aesthetically alluring. additionally, the stitching approach and seam treatment require cautious layout to ensure the jersey’s sturdiness and universal experience of team spirit.

-

Customization: With the diversification of marketplace needs, the customization of sports jerseys is increasingly more valued. Designers offer a spread of selections in styles, colorations, and substances to meet different consumer wishes.

eight. marketplace remarks: After the design of the jersey is finished, it wishes to be examined thru market remarks. Designers will make improvements to the jersey based totally on comments from gamers and fanatics to decorate the product’s market competitiveness.

The layout of sports jerseys is a comprehensive procedure that requires designers to have rich creativity, strong expert information, and keen market perception. through continuous optimization, sports jerseys can’t only offer better athletic reviews for athletes but also serve as an important service for conveying team lifestyle.

Elements of the construction of a sports jersey

surface fabric: The outer layer of sports activities jerseys is commonly crafted from breathable and moisture-wicking synthetic or herbal fibers, such as polyester (puppy), spandex, and cotton, which make sure that athletes remain dry and relaxed all through physical activity.

Lining material: To decorate warm temperature, some sports jerseys consist of lining substances such as polyester or plush, which effectively insulate against the bloodless at the same time as keeping the jersey’s lightness and breathability.

Seam remedy: The seams of a jersey are a crucial part of its production, as appropriate seam treatment can prevent water penetration and growth the jersey’s sturdiness. not unusual seam remedies include heat-sealed bonding and ultrasonic welding.

Collar design: The collar layout extensively impacts the comfort and functionality of a jersey. common collar kinds include round neck, V-neck, and stand-up collar, with each type selected based on the needs of the sport.

Sleeve layout: Sleeve layout is likewise important, affecting the match and balance at some stage in movement. Sleeves can be elastic, improving consolation and versatility.

Pocket layout: The wallet on sports jerseys are normally easy and sensible, designed to maintain small items which includes phones or keys. the position and length of the wallet are designed in step with actual needs.

Zipper and Pull: Zippers are a common purposeful function in jerseys, used for short dressing or adjusting temperature. zippers and pull heads ensure long-time period durability and clean operation.

Shoulder Pads and Straps: In sports that require tremendous shoulder strain, the layout of shoulder pads and straps is specifically vital. They help distribute shoulder stress and alleviate the load on athletes.

Labels and decorations: Labels and decorations on jerseys are not most effective for emblem identification but additionally for cultured enhancement. The design of the labels need to don’t forget their placement, size, and cloth to make certain they do now not have an effect on the jersey’s breathability and functionality.

Embroidery and Printing: The embroidery and printing techniques on jerseys at once have an effect on their look and sturdiness. embroidery and printing make the jersey more delicate and make certain that the patterns do not fade easily.

In summary, the construction of sports jerseys needs to balance comfort, functionality, aesthetics, and durability to meet the needs of various sports.

Garment Material Selection and Manufacturing Process

the selection of cloth for sports jerseys is vital, as it directly affects the consolation, durability, and capability of the jersey. right here are several key points regarding the cloth choice and craftsmanship of jerseys:

material fabric: The fabric for sports jerseys normally makes use of breathable synthetic fibers which include polyester (pet) and spandex. those substances are powerful at wicking moisture and perspiration, retaining the athlete’s body dry. Polyester fibers are lightweight and sturdy, often used for the primary body of the jersey; spandex presents super elasticity and stretch, making the jersey extra body-conforming.

Weaving technique: The weaving approach for jerseys is divided into knitting and weaving. Knitted jerseys provide higher elasticity and luxury, appropriate for the movement of the frame during exercising. not unusual knitting strategies include simple, ribbed, and twill. Weaved jerseys are extra long lasting and appropriate for high-depth sports activities.

Seam remedy: The seams of jerseys are susceptible to wear, so seam remedy may be very critical. techniques which includes warmness-sealed adhesives, bolstered sewing, or ultrasonic welding can beautify the sturdiness of the seams and decrease wear.

Lining design: to enhance the comfort of jerseys, linings are regularly brought. Lining substances generally consist of moisture-wicking cotton or artificial fibers, inclusive of polyester cotton. The design of the lining need to recollect the match and breathability with the outer fabric.

functional info: sports activities jerseys can also upload purposeful information primarily based on special sports activities necessities. as an instance, the neckline of the jersey can also characteristic a low collar to growth neck mobility or a high collar for heat. The sleeve cuffs and leg hems may also use elastic ribbing for ease of wearing and motion.

shade and pattern layout: The color and sample layout of jerseys are also a part of the cloth selection. long lasting dyes and printing strategies are used to make sure the sturdiness of the patterns without affecting the breathability and functionality of the jersey.

Environmental concerns: contemporary jersey production more and more emphasizes environmental concerns, with the use of substances consisting of recycled polyester and organic cotton to reduce environmental impact.

usual Craftsmanship: From fabric reducing to completed product meeting, every process in the manufacturing of jerseys ought to be strictly controlled. This consists of the accuracy of cutting, the neatness of sewing, and the shade coordination of stitching, to make sure the overall fine of the jersey’s craftsmanship.

thru cautious layout in fabric choice and craftsmanship, sports activities jerseys now not handiest meet the athlete’s needs for motion but additionally visually show off the team’s characteristics and style.

Soccer jersey patterns and printing technology

The layout of the jersey pattern is visually attractive, and the combination with printing technology is important. the subsequent is a description of the information of jersey styles and printing technology:

pattern layout:Jersey patterns commonly include factors including the crew brand, numbers, participant names, and sponsor emblems. whilst designing, the following factors need to be taken into consideration:

-

brand and brand: The emblem is the spiritual image of the crew, and it is critical to hold its unique proportions and fashion at some point of the layout procedure to make certain that the visual effect at the jersey is constant with the real.

-

Numbers and Names: Numbers and names are identifiers of the participant’s identity. The font preference should be in concord with the overall style of the jersey, at the same time as making sure readability and readability. The font size and color should be adjusted consistent with the jersey color and cloth.

three. Sponsor emblem: The sponsor brand occupies a positive share on the jersey, and it is critical to make sure that its format is coordinated with the crew brand, numbers, and names, keeping off an abrupt look.

Printing technology:The printing excellent of the jersey sample without delay affects its aesthetics and sturdiness. here are a few commonplace printing technologies:

-

warmness transfer Printing: warmth transfer printing includes transferring the sample onto the jersey fabric through excessive-temperature heating. it’s far suitable for diverse fabric inclusive of cotton and polyester, and has appropriate put on and wash resistance.

-

display screen Printing: display printing involves shifting ink to the cloth via a display screen, forming the sample. This technique is suitable for complex patterns and large-scale production, and is especially value-powerful.

-

Pad Printing: Pad printing entails printing the pattern first on a pad printing paper and then shifting it to the jersey cloth. it’s far suitable for great patterns and small-scale manufacturing, and has excellent shade fidelity.

four. digital Printing: digital printing directly prints the pattern onto the jersey material. it’s far appropriate for personalised customization and small-scale manufacturing, with rapid printing speed and vibrant shades, although its durability is tremendously weaker.

Printing method issues:

-

Ink selection: pick environmentally friendly, UV-resistant, water-proof, and warmth-resistant inks to make certain that the sample does no longer fade over the years.

-

Printing Temperature and pressure: modify the printing temperature and stress in keeping with the fabric and ink characteristics to make sure the clarity and adhesion of the pattern.

-

publish-Processing: After printing, carry out drying and ironing to enhance the general exceptional of the jersey.

The aggregate of jersey pattern layout and printing era is a key element in growing sports jerseys. via carefully designing the pattern and deciding on the proper printing era, jerseys may be both aesthetically fascinating and sturdy, assembly diverse occasions and wishes.

The custom jersey production procedure begins with demand series and proceeds through layout, manufacturing, best inspection, and subsequently product transport, with every step strictly adhering to traditional techniques to make certain the final product’s excessive first-class and client satisfaction.

call for communication: before customization, the manufacturing unit will have interaction in distinctive verbal exchange with the patron to recognize the specific requirements for the jersey, which include style, shade, length, number, sponsor trademarks, and more. the important thing to this level is to correctly hold close the client’s motive to provide a clean course for the following design.

layout Finalization: based totally on the customer’s requirements, the dressmaker will create a preliminary layout thought. The design draft typically consists of the overall format of the jersey, sample layout, and text layout. After completion, the layout must be confirmed via the client. If there are any modifications, the clothier will revise it till the client is glad.

material cutting: After the design is finalized, the reducing section starts. The cloth selection should meet the overall performance necessities for sports activities, which includes breathability and moisture-wicking. all through slicing, unique measurements are taken to make certain that the rims of the cut pieces are neat and unfastened from harm.

sewing technique: The cut fabric is then sewn the use of professional stitching machines. The sewing system consists of stitching,, and becoming a member of, requiring even thread traces and neat seams without any unraveling. special interest is given to the stitching of precise regions which include sleeve cuffs and collars to make certain consolation and aesthetics.

Printing ornament: The printing of patterns and textual content on the jersey is a critical step. strategies consisting of display screen printing, heat transfer, and digital printing are used to make sure that the patterns are clean, hues are colourful, and the print is long lasting and put on-resistant. before printing, the sample have to be previewed to make sure that the printing impact meets expectancies.

fine Inspection: After production is entire, a complete pleasant inspection is carried out. Inspection items encompass stitching best, cloth excellent, printing pleasant, and dimensional accuracy. If there are any items that don’t meet the standards, they may be right away corrected.

Packaging and garage: merchandise that bypass the best inspection are packaged, the use of dust bags or cardboard boxes for safety to save you harm for the duration of transportation. After packaging, the goods are stored in inventory prepared for shipment.

transport: in line with the client’s asked delivery method, such as express delivery or logistics, cargo is arranged. earlier than shipment, the order data is established to make certain accuracy before the cargo operation is performed.

After-sales carrier: After product transport, vital after-sales provider is provided, which includes answering utilization questions and supplying renovation steerage. via appropriate after-income service, client satisfaction and emblem image are greater.

Quality Inspection and Control of Football Shirt Fabric

The nice inspection of football shirts covers multiple components, inclusive of cloth, stitching, printing, and functionality. the following is an in depth description of every inspection level:

-

material Inspection: The cloth of the soccer shirt is the foundation for its consolation and durability. The inspection manner consists of rigorous exams on indicators inclusive of fiber composition, colour fastness, shrinkage price, and breathability. The fiber composition have to follow the product label, colour fastness checks make certain that the colours do now not fade at some point of washing, shrinkage rate controls the dimensions adjustments of the material after washing, and breathability checks make sure that the shirt gives properly air flow all through exercising.

-

sewing satisfactory test: sewing is a important stage inside the production of football shirts, directly affecting their durability and look. The exams encompass whether the sewing is even, the ends of the threads are smartly trimmed, and the seams are strong. expert inspectors will check each item in my view to make certain that the sewing satisfactory meets the standards.

-

Printing impact evaluation: The patterns and symbols at the soccer shirts are critical representations of the logo and crew photograph. The assessment of the printing impact includes the clarity of the sample, the vibrancy of the colors, and the combination of the sample with the cloth. Inspectors will use magnifying equipment and different expert device to check whether the printing pattern is clear, freed from blurring or discoloration.

four. capability trying out: sportswear requires sure useful properties, which include moisture-wicking and quick-drying. Inspectors will conduct moisture-wicking performance assessments at the shirts below simulated exercising situations to ensure they stay dry and relaxed all through physical activity.

five. Zipper and Button Inspection: Zippers and buttons on football shirts are prone elements and are a key focus of exceptional manipulate. The assessments include the smoothness of the zipper, the firmness and sturdiness of the buttons. All zippers and buttons must bypass a couple of opening and final checks to ensure they do no longer fail below normal use.

-

size and healthy test: the size and healthy of soccer shirts immediately have an effect on the consolation and aesthetics of wearing. Inspectors will degree each blouse towards the same old length chart to make sure compliance with the specs. additionally they check the suit and whether the strains are smooth and flowing.

-

protection performance evaluation: For expert team football shirts, protection overall performance is also an essential part of the inspection. This consists of checking for flammable materials, sharp edges, or protrusions that would purpose harm.

eight. Packaging and Label Inspection: finally, the packaging and labeling of the football shirts are checked to ensure that every shirt is packaged nicely and the labels incorporate correct facts, consisting of brand, version, length, washing commands, and so on.

through those complete inspections, every soccer shirt is ensured to go through strict fine control earlier than leaving the factory, meeting the customer’s usage wishes, and also retaining the logo’s image and recognition.