Enhancing Sports Jersey Quality Control with IT and Innovative QC Practices

The high-quality of sports jerseys, as an indicator product within the sports field, directly affects the comfort of athletes, the team’s photo, and the popularity of the logo. therefore, great manage within the manufacturing technique of sports jerseys is critical. this newsletter will discuss the key great manage points in the manufacturing process of sports jerseys, which include material inspection, manner drift monitoring, finished product inspection, and elements along with nice remarks and continuous development.

Quality Control Overview

In the process of producing sports team jerseys, quality control (QC) plays a crucial role. It ensures that every jersey meets the established quality standards, thus satisfying consumer demands and the expectations of sports teams. Below is an overview of some core elements of quality control in the production of sports team jerseys.

Quality control begins with the selection of raw materials. Ensuring that the fabrics, threads, buttons, and other accessories used meet international standards is crucial for the quality of the final product. The quality of these materials directly affects the durability, comfort, and functionality of the jerseys.

Every step of the manufacturing process must undergo rigorous inspection. From cutting to stitching, each procedure should be ensured to be precise and accurate. Professional measurement tools and inspection methods are used to monitor dimensions, alignment, and stitching tightness, among other factors.

Color management is a significant component of quality control. The bright and consistent colors of sports team jerseys are achieved through professional color matching and printing techniques. During the printing process, color consistency, pattern clarity, and durability are all key points to focus on.

Functionality testing is also indispensable. The design of sports team jerseys must consider the needs of athletes, so tests on breathability, moisture absorption, and elasticity are necessary. These performance tests help ensure the comfort and functionality of the jerseys during exercise.

The final inspection stage of finished products involves checking each jersey from multiple angles and aspects. This includes (appearance check), size check, stitching check, and functionality tests. Any product that does not meet the standards is removed from the production line.

Quality records and traceability are also critical to quality control. Detailed records of each batch of materials and production are kept to allow for rapid tracing back to the source in case of problems, ensuring that issues are effectively resolved.

Customer feedback is the driving force behind the continuous improvement of quality control. Collecting feedback from customers, analyzing the issues at hand, helps to continually optimize the production process and enhance product quality.

In summary, quality control for sports team jerseys involves every aspect from raw material selection to final product inspection. Through meticulous management, continuous improvement, and innovation, quality control ensures the quality of sports team jerseys and provides athletes with the best athletic experience.

Key Quality Control Points in the Production Process of Sportswear

Quality Control Points in the Production Process of Sports Jerseys

The quality control is the key to ensuring the product quality in the production of sports jerseys. The following are several key points for quality control:

Fabric Selection and InspectionThe production of sports jerseys begins with the selection of fabric, which must be chosen for its performance and comfort. The fabric must undergo strict inspections for durability, color fastness, and breathability to ensure the stability of fabric quality and meet the performance requirements during exercise.

Cutting AccuracyCutting is a critical step in the production process, requiring precise dimensions and clean edges of the cut pieces. Cutting errors directly affect the size and appearance of the finished product, therefore, the use of high-precision cutting equipment and strict control over the cutting process is essential to guarantee jersey quality.

Sewing TechniqueSewing is the core process in jersey making, including stitching, hemming, and techniques. The quality of the stitching directly affects the durability and aesthetics of the jersey. Strict control over thread quality, stitch density, and sewing tension ensures that the seams are firm and free from skipped stitches or unraveling.

Pattern PrintingPattern printing is the characteristic expression of the jersey, requiring clear printing, vibrant colors, and resistance to fading. Attention must be paid to the quality of the ink, the adjustment of the printing machine, and the drying treatment after printing to ensure the quality of the pattern.

Assembling and AssemblyAssembling involves piecing together the cut fabric, while assembly is the process of combining all parts into a complete jersey. This stage requires accurate assembly positions and precise alignment of the components to avoid misalignments or misseams.

Dimension Measurement and AdjustmentAfter assembly, the jersey is measured for dimensions to ensure that the finished product meets the standard. If there are deviations, adjustments are made in a timely manner to ensure the comfort and uniformity of the jersey.

Final Product InspectionThe final product inspection is the last step in the production process, involving a comprehensive check of the jersey’s appearance, size, and functionality. Inspection items include stitching quality, fabric performance, pattern printing, and dimensional accuracy to ensure that all products meet quality standards.

Packaging and ShipmentQualified jerseys are packaged according to transportation and storage requirements to ensure that the product is not damaged during transport. Before shipment, the order information is checked again to ensure accuracy before dispatching.

Through these quality control points, it can be ensured that sports jerseys meet high-quality standards in all production stages, satisfying consumer needs and market expectations.

Material Inspection and Standards

Material inspection is the first quality control checkpoint in the production of sports team jerseys, ensuring that the materials used meet the established standards is crucial. The following are several key inspection steps:

-

Fabric Inspection: Fabric forms the foundation of the jersey and its quality directly affects the comfort and durability of the garment. The inspection includes checking for uniformity of color and pattern, the absence of color variations, stains, or damage. Additionally, the density and weight of the fabric must be checked to ensure they meet the specified requirements.

-

Accessories Acceptance: Accessories such as zippers, buttons, and labels, although small, can affect the overall quality. The inspection of accessories should focus on their material, color, size, and whether they match the design, as well as the presence of any defects or damage.

-

Sewing Thread Inspection: The strength and corrosion resistance of the thread are crucial for the durability of the jersey. The inspection of the thread should include checking its color, thickness, and breaking strength to ensure the stability of the thread quality.

-

Functional Testing: For special function fabrics, such as breathable, quick-drying, or anti-static, functional testing is required to ensure that the fabric performance meets product requirements.

-

Environmental Standard Testing: With the increasing awareness of environmental protection, the environmental performance of sports team jerseys has also become a focus of inspection. It is necessary to test whether the fabric contains harmful substances such as formaldehyde and heavy metals to ensure that the product meets environmental standards.

-

Dimension and Specification Verification: Before materials are stored, dimensions and specifications must be verified to ensure that the material dimensions are accurate, avoiding waste or production delays due to incorrect sizes.

-

Batch Inspection: Sampling inspection of the same batch of materials is conducted to ensure the consistency and stability of the entire batch.

-

Supplier Assessment: Regularly assess suppliers to ensure the stability of the quality of materials they provide, and to continuously improve supply chain management.

Through these material inspection and standard control measures, the quality of sports team jerseys can be effectively guaranteed, providing consumers with high-quality products.

Process Flow Monitoring

In the production process of sports team jerseys, process monitoring is a critical link in ensuring product quality. The following is a detailed description of this stage:

Accurate Cutting: At the initial stage of production, it is necessary to accurately cut the fabric. Monitors must ensure that the cutting dimensions are precise and the fabric is aligned neatly, avoiding waste and substandard products caused by cutting errors.

Sewing Technique: Sewing is the core link in the production of jerseys. Monitors need to pay attention to the operating status of the sewing machines, check the density and flatness of the stitching, and look for issues such as skipped stitches or broken threads. Moreover, the monitoring needs to be more stringent for details such as seams, collars, and cuffs.

Printing and Heat Transfer: For jerseys with team logos, numbers, and other patterns, the printing and heat transfer processes are equally important. Monitors must check the clarity, positional accuracy, and color consistency of the patterns to ensure that each jersey’s personalized elements meet the expected effects.

Zipper and Buttons: The quality of metal accessories such as zippers and buttons on jerseys directly affects the wearing experience. Monitors need to check the durability, flexibility in operation, and the tightness of the fit with the garment, ensuring that the accessories are durable and do not affect the appearance.

Detail Handling: In the later stage of the production process, detailed checks of the jersey are also required. This includes aspects such as the stitching of pockets, the trimming of the hem, and the shape of the collar, all of which require strict control by monitors to ensure that each detail meets the design requirements.

Final Inspection: After each stage of the production process, final product inspections should be conducted. Monitors need to observe each finished product as a whole, checking for any obvious flaws, deformities, or other areas that do not meet the standards.

Quality Records: Throughout the monitoring process, issues found should be recorded in detail. This not only helps in tracing the causes of problems but also provides data support for production optimization and quality improvement.

Regular Training: To ensure the capabilities and knowledge level of monitors, production factories should provide them with regular training, update process knowledge, and improve monitoring efficiency and accuracy.

Continuous Improvement: Through process monitoring, manufacturers can timely identify and solve problems, continuously optimize production processes, and improve the overall quality of sports team jerseys.

In the process of producing sports jerseys, the final quality check is a crucial step to ensure product quality. Here is a detailed description of this stage:

Detailed Sewing Inspection: Carefully observe the stitching lines of the jersey to ensure that all seams are even and secure, without any skipped, broken, or loose threads. Check that the seams are straight and there are no misalignments or overlaps.

Fabric Testing: The finished garment fabric must undergo performance tests such as tensile strength, abrasion resistance, and shrinkage rate to ensure that the fabric quality meets national standards. The fabric’s maximum carrying capacity and elastic recovery during stretching are measured by instruments.

Color and Pattern Inspection: Observe the uniformity of the jersey’s color, check for any color discrepancies, and ensure that the pattern printing is clear, the positioning is accurate, and the colors match the sample.

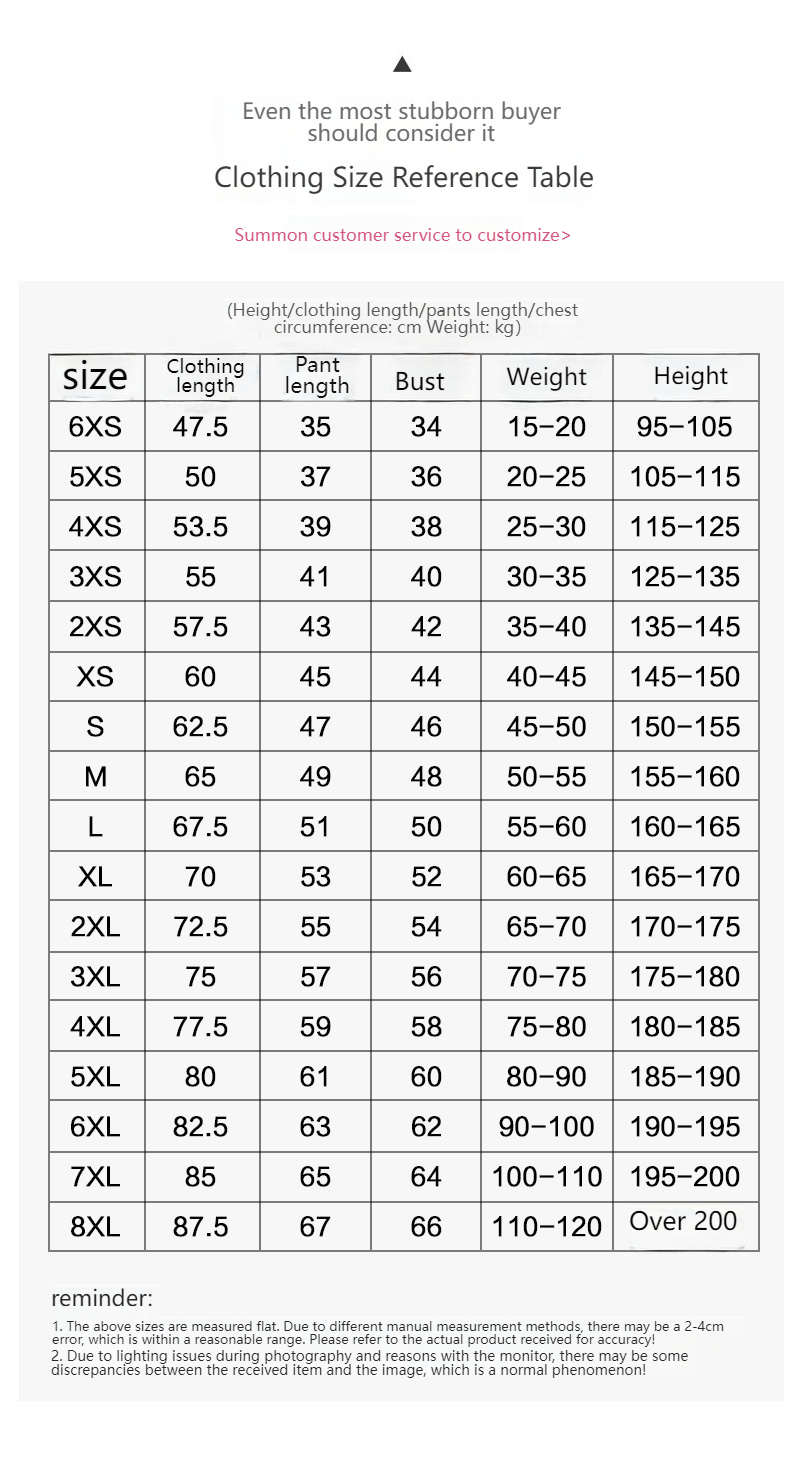

Size Measurement: Measure the dimensions of the jersey’s various parts according to the standard size chart, including bust, shoulder width, sleeve length, and garment length, to ensure that the finished product sizes are accurate.

Functional Testing: For jerseys with special functional designs, such as breathability and moisture-wicking, professional testing instruments must be used to verify that the functional performance meets the expected effects.

Feel and Appearance Assessment: Through manual touch and visual observation, check the overall feel of the jersey, ensuring it is soft and comfortable, and that there are no burrs, pilling, or other issues on the surface.

Label and Tag Inspection: Verify all label and tag information, including the brand logo, size, care instructions, and safety warnings, ensuring that the labels are securely attached and the information is accurate.

Packaging Inspection: Before the finished jerseys are packed, check that the packaging boxes are intact, free from damage or deformation, and that the jerseys inside are neatly arranged to prevent damage during transportation.

Through these multiple inspections, every jersey is ensured to meet the established quality standards and satisfy consumer demands for product quality. At the same time, the quality inspection standards for finished products will continue to be updated and improved in line with market demands and industry standards.

Quality Feedback and Continuous Improvement

In the production process of sportswear, quality feedback and continuous improvement are crucial for the continuous enhancement of product quality. The following is a detailed description of this phase:

-

User Feedback Collection: Collect consumer feedback on the wearing experience, comfort, durability, and other aspects of the sportswear through various channels such as sales outlets, social media, and customer service hotlines. This information helps to understand the performance of the product in actual use and identify potential problem areas.

-

Internal Quality Assessment: The production department conducts internal quality assessments for each batch of products, including appearance checks, size measurements, and functional tests. The results of the assessments are used to identify defects and shortcomings in the production process.

-

Problem Analysis and Resolution: Analyze the causes of the problems identified from the collected feedback and internal assessments, such as material issues, process defects, and equipment malfunctions. Develop solutions for specific problems and implement improvement measures.

-

Implementation of Improvement Measures: Adjust the production process based on the analysis results, such as optimizing raw material procurement, improving production techniques, and updating equipment. Additionally, train employees to ensure effective execution of the new measures.

-

Monitoring the Effectiveness of Improvements: After implementing the improvement measures, track and inspect the products to assess the effectiveness of the improvements. If the results are significant, continue to execute them; if not, reanalyze the causes and adjust the improvement strategy.

-

Documentation and Updating: Record all improvement measures, analysis results, and testing data, and regularly update them. These documents provide references for subsequent production and quality control.

-

Continuous Optimization: Continuously introduce new technologies and materials in product design and production, optimize product structures, and enhance product performance. Additionally, stay informed about industry trends and learn from advanced experiences to continuously improve product quality.

-

Enhancement of Customer Satisfaction: Through continuous improvement, enhance the overall quality of sportswear, thus improving customer satisfaction. Satisfied customers lead to word-of-mouth promotion, which helps to elevate the brand image.

-

Internal Communication and Training: Strengthen communication and collaboration between departments such as production, quality, and sales to ensure the effective execution of improvement measures. Additionally, conduct quality awareness training for employees to enhance overall quality consciousness.

-

Long-term Strategic Planning: Incorporate quality feedback and continuous improvement into the company’s long-term strategic plan to ensure that product quality always remains at the forefront of the industry.

Please provide the content to be translated so that I can assist you with the translation.

The first-class of sports apparel is a important assure for emblem image and purchaser pleasure. by setting up a complete high-quality comments and continuous improvement mechanism, companies can constantly beautify product best to satisfy marketplace needs.

inside the marketplace remarks segment, corporations collect recommendations and evaluations from consumers. these feedbacks can also contain components including the consolation, sturdiness, coloration accuracy, and length compatibility of the garb. via professional facts analysis, agencies can discover in which their merchandise fall short and wherein they’re nicely-obtained through clients.

In response to the troubles raised within the feedback, corporations will prepare cross-departmental teams to research and discuss them, pinpointing the foundation reasons. as an example, if consumers file that the garb is liable to fading, the team will have a look at the dye selection, dyeing technique, and post-processing methods. In response to these issues, the enterprise will regulate formulas, improve methods, or optimize post-processing steps.

during the non-stop improvement manner, the enterprise will introduce new technologies and management strategies. for instance, the use of extra advanced trying out device to ensure the high-quality of raw substances, implementing stricter technique manipulate techniques, and making use of exceptional management tools inclusive of Six Sigma to lessen disorder fees.

The business enterprise may also train its employees to beautify their exceptional consciousness and technical competencies. employees are the key to excellent improvement, and via education, they are able to better recognize the importance of product quality and grasp the competencies to remedy practical troubles.

within the product improvement segment, the business enterprise additionally makes a speciality of innovation, constantly learning and developing new technologies and materials to improve the overall performance and comfort of the garb. on the equal time, via market research, the organization is familiar with new purchaser demands for sports apparel, taking into consideration corresponding modifications in product design and production.

In terms of deliver chain management, the employer will establish lengthy-time period cooperative relationships with providers to make sure the high-quality and stability of uncooked cloth supply. at the same time, via provider evaluation and certification, every link of the deliver chain is ensured to fulfill the company’s quality standards.

in the end, thru excellent comments and continuous development, organizations cannot best beautify the market competitiveness in their products but additionally toughen brand loyalty. customer reputation of sports clothing will without delay translate into the economic and social advantages of the employer.

In concept, the production of sports garb is a scientific challenge, from raw material procurement to finished product shipment, every degree is associated with the very last exceptional of the product. by using setting up a complete great remarks mechanism and constantly optimizing the process float, groups can make sure that every piece of clothing meets excessive standards, meets client expectancies, and maintains a leading function in fierce market competition.