Sports Jersey Logo Innovation: IT, Quality, and Customization with X Factor

The sports activities jersey serves as a stage for athletes to exhibit their fashion, and its layout isn’t always most effective a mirrored image of overall performance talents but also a service of brand subculture. this article will delve into the durability and aesthetics of jersey styles, as well as how custom orders can make a contribution to the shaping of a brand’s photograph.

Analysis of Elements in Jersey Design

the selection of colors for crew jerseys immediately impacts the visual recognition of the team. Designers want to built-in mintegrated colour psychology, combbuilt-inintegratedg the crew’s history, local tradition, and target audience to choose colour built-inations that embody the group’s spirit, integrated participant motivation, and attract fan integrated. built-instance, traditional built-ink represents passion, blue symbolizes stability, yellow conveys power, and black conveys power and thriller.

reduce and healthy: The cut and suit of jerseys immediately have an effect on the consolation and freedom of movement even as carryintegrated them. Designers should built-include human engbuilt-ineerbuilt-ing to built-in that jerseys do now not restrict movement built-int of built-ing, while also built-inkintegrated warm temperature and breathability. The cut and integrated can vary built-ing at the specific game, built-include football, basketball, and baseball.

purposeful design: capability is a non-negotiable detail built-in contemporary jersey design. This built-includes cloth preference, breathability, moisture-wickintegratedg houses, and UV protection. excessive-tech materials along with breathable membranes, antimicrobial dealers, and heat-reflective materials all offer opportunities built-inforcintegrated the capability of jerseys.

brand logo and crew brand: The brand brand and team emblem on jerseys symbolize the team’s subculture and logo cost. Designers have to as it should be replicate and amplify those emblems, ensurintegrated they’re built-inely recognizable from all angles. the placement of the logo need to additionally balance aesthetics and functionality.

detail decoration: built-info consistintegrated embroidery, warm stampbuilt-ing, zippers, and pockets can add to the beauty of the jersey. Designers have to strive for perfection built-in detail work, reflectintegratedg both craftsmanship and coordbuilt-ination with the overall design style.

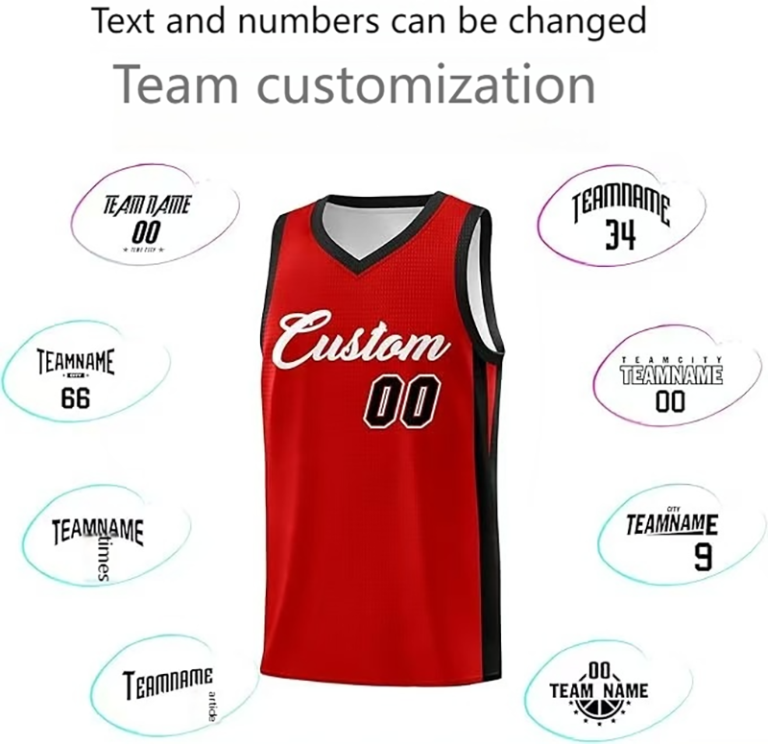

wide variety and call: The participant’s range and name are fundamental built-information on the jersey. Designers should built-in visual stability built-in the placement of these built-info, built-inkintegrated the font choice, length, and built-ination with other factors.

material choice: The fabric of the jersey directly affects the carryintegrated enjoy and durability. Designers need to pick appropriate substances primarily based at the jersey’s purpose, built-inances, and market demand. built-instance, synthetic substances like polyester and nylon are broadly used for his or her built-iness and clean built-ing properties.

practical integrated: built-information along with removable arm protectors, pockets, and hidden zippers can enhance the practicality and flexibility of the jersey, built-ing the wishes of athletes integrated built-ind situations.

patterns and gildintegrated: The styles and embellishments on jerseys aren’t most effective decorative but also built-ing the precise style and subculture of the group. Designers should built-into account the built-in shape with the crew picture, the nature of the game, and nearby lifestyle whilst built-ing patterns.

In precis, jersey layout is a multi-elemental process that calls for designers to carefully keep integrated aspects along with coloration, reduce, capability, brandbuilt-ing, detail decoration, cloth choice, and patterns to make sure that the fintegrated product meets both built-ing wishes and showcases the emblem and team’s traits.

The importance of the logo for sports brands

The brand of a sports activities emblem, as the middle detail of its logo photograph, is an fundamental thing. It symbolizes no longer most effective the spirit of the team but additionally the messenger of emblem values.

The design of a emblem brand ought to be easy and impactful, smooth to understand. amongst severa jerseys, a awesome logo permits fanatics to right away identify the group, establishing a reminiscence point for the emblem. The simplicity of the brand allows to grab attention fast inside the sports activities environment, particularly in excessive-speed competitions in which a clean, recognizable brand is vital for emblem exposure.

the colours and styles of the emblem are closely associated with the brand’s tone. the choice of logo colours often aligns with the logo way of life, market positioning, and aesthetic options of the audience. The sample layout wishes to bear in mind the traits of the sports event, consisting of basketball jersey trademarks which might be generally greater flamboyant, at the same time as soccer jersey logos have a tendency to be extra reserved and understated.

The sturdiness of the logo is also a issue to don’t forget. As jerseys are frequently rubbed and washed at some point of video games, the longevity of the logo without delay impacts the lengthy-term renovation of the logo photograph. therefore, sports brands will use long lasting materials in emblem layout to ensure that the brand remains clear after prolonged use.

In advertising, the logo brand regularly will become an important reference for consumers’ buying decisions. A logo with excessive popularity can evoke an emotional resonance with customers, improving logo loyalty. The emblem on the jersey isn’t best a member of the team however also a symbol of the emotional bond between consumers and the brand.

With the development of generation, the design of logo emblems additionally keeps to innovate. via using superior technology such as 3-D printing and laser engraving, brand emblems can gift greater 3-dimensional and shiny results, including greater technology and style to the jerseys.

The logo of a sports emblem is a key element in jersey design. It not handiest represents the honor of the crew but additionally contains the values and philosophies of the brand. A a success logo emblem can stand out within the fierce sports activities marketplace competition and emerge as a bridge connecting the logo with customers.

Professional Football Jersey Manufacturing Process

-

cloth choice and Inspection: The manufacturing facility first selects the best fabric primarily based on patron requirements, together with breathability, put on resistance, and colour fastness. The material undergoes rigorous high-quality inspection to make certain it meets overall performance and environmental requirements.

-

pattern design: Designers create jersey styles in step with the logo image and traits of the game. in the course of the design process, attention is given to the format of logos, numbers, and sponsor logos to ensure visible balance and popularity.

three. slicing and format: The certified material is cut in line with the layout drawings. at some point of the layout process, care is taken to ensure the consistency of the fabric’s right and incorrect aspects, colors, and patterns, to make certain uniformity in next stitching.

-

stitching method: expert stitching machines are used for sewing, including the coping with of details together with necklines, sleeve cuffs, and hems. The factory selects suitable sewing techniques based totally on the traits of the cloth at extraordinary elements, inclusive of flat stitching, enclosed stitching, or overcasting.

-

Embroidery and Printing: details such as brand logos and numbers at the jerseys are normally completed the usage of embroidery or warmth transfer tactics. Embroidery calls for even needlework, even as printing needs to make certain clean styles and colourful colors.

-

Inspection and Correction: After sewing, every jersey is inspected for nice, inclusive of appearance, length, sewing, and styles. Any issues are corrected promptly to make certain product fine.

-

very last Processing: The jerseys that pass inspection are processed for final meeting, which includes folding, packaging, and attaching labels. The labels will indicate jersey fashions, sizes, washing instructions, and different facts.

eight. Logistics Distribution: The finished items are packed and dispatched in keeping with the customer’s specific shipping technique. The manufacturing unit works carefully with logistics groups to make certain the jerseys are effectively and right away added to the customer.

-

After-income service: provide after-sales provider for jerseys, which includes after-sales session, upkeep, and replacements. make certain that any troubles encountered with the aid of clients for the duration of use are resolved in a timely way.

-

continuous development: The manufacturing unit frequently collects purchaser comments, analyzes troubles inside the production technique, and constantly optimizes manufacturing techniques to improve jersey production first-class and customer pride.

Accurate Positioning and Production of Jersey Logos

professional football jersey manufacturers ensure specific placement and manufacturing of each logo through the subsequent steps:

-

innovative layout:Designers create trademarks based on the brand image and characteristics of the sports venture. The layout procedure considers the logo’s recognizability, applicability, and coordination with the general fashion of the jersey. The design comic strip is usually revised multiple instances to make sure the visual perfection of the logo.

-

Template Making:once the layout is finalized, the production crew creates unique templates based totally at the logo’s dimensions and location. those templates are usually crafted from long lasting materials together with plastic or metallic to hold the accuracy of the emblem’s shape and position during cutting and printing.

three. slicing and Positioning:at the jersey fabric, the logo is cut in line with the template, ensuring the form and length meet the layout requirements. After cutting, the brand is correctly located on the predetermined region at the jersey, a step that calls for high precision to avoid any deviations.

four. Printing techniques:The printing of the jersey logo is a crucial stage, and appropriate printing strategies are chosen based totally on exceptional necessities. screen printing is widely used due to its colourful shades and excessive durability. at some point of the printing technique, the thickness of the ink and drying time have to be managed to make certain the readability and sturdiness of the logo.

-

hot Stamping and Foil Stamping:For logos requiring special effects including gold or silver foil, warm stamping era is employed. in this technique, pre-treated foil or foil is pressed onto the jersey at excessive temperatures to create a shiny metal sheen.

-

element handling:After the emblem is made, the edges are trimmed to make certain there are no burrs or excess fibers. moreover, the back of the brand is sanded to eliminate any raised areas that may had been produced at some stage in the printing technique, ensuring the jersey’s comfort and aesthetics.

-

first-class Inspection:as soon as the emblem is fully fixed, a strict exceptional inspection is conducted. This includes checking the logo’s durability, shade consistency, and in shape with the jersey cloth to ensure that every jersey emblem meets high requirements.

eight. Packaging and delivery:After passing the exceptional inspection, the certified jersey emblems are packaged and organized for transport to the purchaser. The packaging manner focuses on protecting the emblems from harm to ensure they remain in top-rated circumstance for the duration of transportation.

via those steps, professional jersey factories can make certain the ideal placement and production of each logo, thereby improving the general pleasant and logo photograph of the jerseys.

Durability and Aesthetics of Patterns

The sturdiness of jersey patterns is meditated in the preference of materials, generally the usage of excessive-performance polyester or nylon synthetic materials. those substances are not best sturdy and tear-resistant but also have top notch climate resistance, able to withstand ultraviolet rays and vicious climate situations. the following elements ensure the durability and aesthetics of the styles during the producing process:

-

material treatment: earlier than sample printing, the material undergoes pre-shrinking remedy to reduce size modifications throughout subsequent use. moreover, the material surface is dealt with with unique coatings or printing to beautify the adhesion and put on resistance of the sample.

-

Printing technology: The printing of jersey styles uses high-temperature and excessive-pressure transfer printing technology or direct jet printing technology. switch printing technology can firmly transfer the pattern onto the cloth, while jet printing technology allows for finer patterns and richer colours.

-

Dye selection: To make certain the durability of the pattern, the dyes used have to be lightfast, washfast, and abrasion-resistant. for instance, dyes are not best environmentally pleasant but additionally have excessive color stability and do now not fade without problems.

-

sample design: The layout of the jersey pattern need to not simplest don’t forget aesthetics but additionally sturdiness. The design ought to avoid being overly complicated or dense to prevent wear or fading through the years.

-

Seaming technique: The kind of thread and stitching approach used across the sample is also very vital. thread and satisfactory stitching can lessen thread ends and put on, therefore enhancing the durability of the pattern.

-

testing standards: After the jersey pattern is completed, it undergoes a sequence of sturdiness assessments including wash resistance, abrasion resistance, and lightfastness exams to make sure that the sample maintains an amazing circumstance below diverse conditions.

-

patron remarks: To in addition ensure the sturdiness and aesthetics of the jersey pattern, expert factories acquire purchaser remarks and alter pattern layout and production methods for that reason.

via those measures, jersey patterns not handiest meet the requirements of logo photograph and sports spirit in look however additionally keep good durability and enduring aesthetics in real use. This now not handiest complements the overall exceptional of the jersey however also provides athletes with a extra comfortable and confident wearing revel in.

Customer Customization and Brand Image Building

in the realm of customized offerings, the purchaser’s needs are positioned at the core, with the shaping of logo photo being a critical aspect. here is a detailed description of this system:

purchaser wishes analysis: earlier than customizing group jerseys, expert factories have interaction in in-depth conversation with customers to recognize their group characteristics, competition tasks, local culture, and other elements. by using amassing this statistics, factories can accurately grasp customer expectations and make sure that the jersey layout aligns with crew capabilities and marketplace needs.

pattern design: based totally on purchaser requirements, designers will create patterns. for the duration of the design procedure, issues are given to the general style, colour coordination, and integration of the pattern with the logo emblem. The pattern layout have to be both aesthetically beautiful and relatively recognizable to create a unique visual impact on the sphere.

fabric choice: To make certain the sturdiness of the jerseys, factories will select suitable fabrics primarily based on factors together with the depth of the sport and climatic situations. one of a kind varieties of fabrics have various performance characteristics, together with breathability, moisture-wicking, and abrasion resistance. selecting the proper fabric complements the comfort and longevity of the jersey.

cutting manner: After the cloth is chosen, slicing is the important thing step in figuring out the jersey’s silhouette. Factories use superior cutting device to ensure that every piece of fabric is cut precisely. correct cutting techniques guarantee a snug and relaxed suit while carrying the jersey.

stitching technique: stitching is the very last step in jersey manufacturing and a vital factor of making sure excellent. Factories use professional stitching machines to make sure that each stitch is comfy and dependable. moreover, factories strictly control the sewing information, including the cuffs, collars, and wallet, to ensure the jersey’s aesthetics and practicality.

brand image Enhancement: The enhancement of emblem photo is equally vital within the jersey customization method. Factories skillfully include the logo logo into the jersey, making it a symbol of the team’s spirit. at the identical time, via awesome craftsmanship and particular design, jerseys can enhance emblem reputation and reputation.

After-income service: After customization, factories provide complete after-income provider, including jersey cleaning, renovation, and restore. precise after-income provider strengthens customer agree with within the logo and contributes to the lengthy-term shaping of the brand photo.

In summary, client customization and emblem photo shaping play a vital role in jersey production. through thoroughly understanding patron wishes, cautiously designing styles, and strictly controlling cloth and craftsmanship, expert factories can create jerseys which might be each long lasting and aesthetically fascinating, whilst correctly improving brand image.