Sports Jersey Clothing: The IT Factor with Innovation and Quality Experience

The jersey, as a image of sportsmanship, not simplest embodies the elegance of athletes but also serves as a bridge connecting fans to the subculture of sports activities. this article will explore the precise position of the jersey in sports subculture, in addition to the meticulous craftsmanship at the back of its layout and production.

Overview of Production

The production of sports uniforms, as a signature equipment of sports, integrates modern textile technology, design concepts, and efficient management. From raw materials to finished products, the manufacturing process of a sports uniform involves multiple stages to ensure that each piece meets both performance and aesthetic requirements.

Fabric is the foundation of uniform production, typically using high-tech materials such as breathable, quick-drying, and antimicrobial fabrics. These materials not only enhance the athlete’s comfort but also improve their performance. In the early stages of production, fabrics undergo strict selection and inspection to ensure they meet international standards.

Cutting and sewing are the core processes in uniform production. Professional equipment ensures precise sizing for each uniform, while advanced sewing techniques guarantee strong and aesthetically pleasing seams. During cutting, functional designs are also implemented based on the specific needs of different sports, such as adding reflective strips to improve nighttime safety.

Design elements are the soul of the uniform. Brands often combine the characteristics of the sport, cultural background, and market demands to create unique uniform styles. Design teams use professional software for pattern drawing and layout to ensure that the patterns perfectly match the uniform’s cut. The color matching and integration of brand logos are also crucial aspects of the design.

Quality control is an indispensable part of the manufacturing process. From raw material procurement to finished product dispatch, every step is strictly monitored for quality. This includes comprehensive monitoring of fabric quality, cutting dimensions, sewing techniques, and color accuracy. Only uniforms that pass quality inspections are eligible for market sale.

With the changing market demands, the production of sports uniforms is also continuously adjusted and upgraded. In recent years, environmental protection and sustainability have become industry trends, with many brands starting to use eco-friendly fabrics and biodegradable materials for making uniforms. Moreover, intelligent and digital applications are being utilized in the production process, such as real-time production data monitoring through smart devices to improve production efficiency and product quality.

Sports uniforms are not only athletes’ competitive equipment but also carriers of sports culture. From professional leagues to amateur competitions, uniforms carry the emotions of fans and the brand’s philosophy. During the design and production process, brands consider how to transform the uniform into a cultural symbol, allowing consumers to feel the charm of sports while wearing them.

The production of sports uniforms is a complex and meticulous process, with every step reflecting a pursuit of quality and sensitivity to the market. As technology develops and consumer demands evolve, the sports uniform manufacturing industry is continuously innovating to adapt to future trends.

Fabric Selection and Technique

the choice of cloth in the production of soccer jerseys performs a critical role, at once affecting the comfort, sturdiness, and appearance of the jerseys. under is a detailed description of the cloth selection and processes concerned:

soccer jerseys usually use the subsequent kinds of fabric:

-

Cotton material: Cotton material has proper moisture-wicking and breathability, supplying comfort suitable for spring and autumn seasons. In jersey production, cotton cloth is often used for the lining to beautify the softness and pores and skin-friendliness of the jersey.

-

Polyester fabric: Polyester material is long lasting, smooth to wash and dries fast, making it one of the maximum normally used fabric in jersey manufacturing. it’s far suitable for making the outer layer of jerseys, imparting exact guide and safety.

three. Nylon fabric: Nylon cloth is lightweight and durable, typically used for the collars and cuffs of jerseys, which can be liable to wear, to beautify the durability of those regions.

four. mixed fabric of natural and artificial Fibers: to combine the advantages of various fabrics, jersey manufacturing frequently employs mixing era of herbal and artificial fibers. for example, cotton-polyester combined cloth retains the consolation of cotton whilst additionally having the durability of polyester.

Jersey manufacturing methods include:

-

Weaving: depending at the sort of cloth, the weaving manner for jerseys varies. Cotton material is regularly woven in simple weave, even as polyester fabric normally uses twill weave.

-

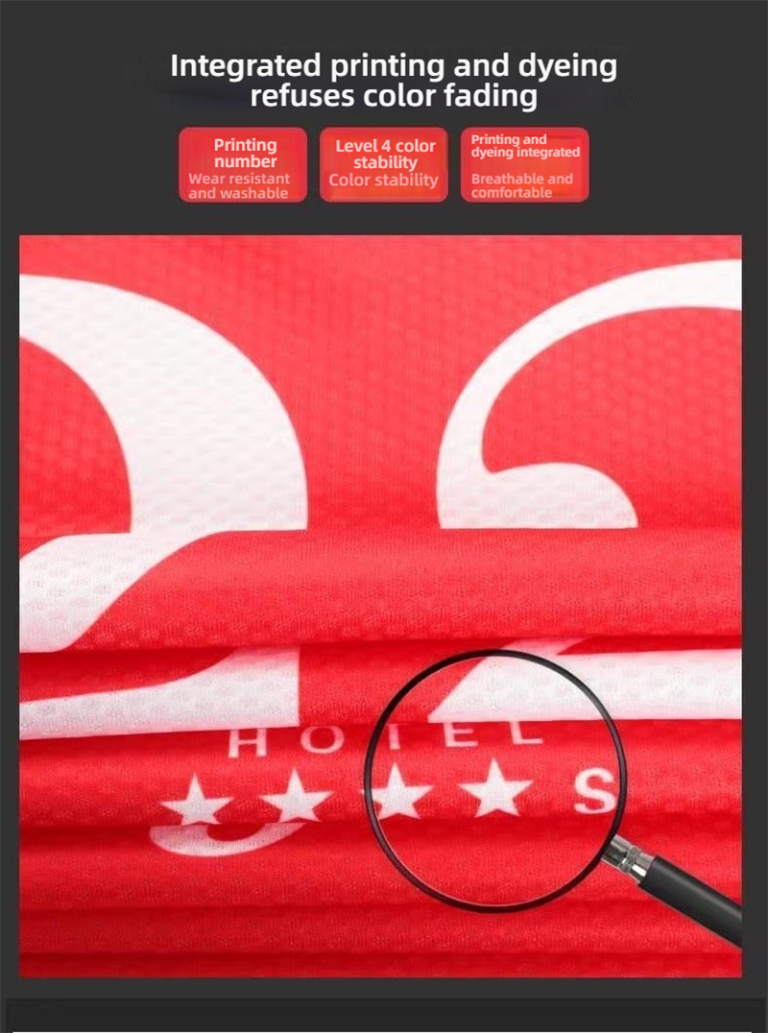

Dyeing: After weaving, jersey material undergoes dyeing remedy. Dyeing tactics encompass direct dyeing and reactive dyeing, aimed toward ensuring the vibrancy and washfastness of the jersey hues.

three. Printing: to add personalization to jerseys, group logos, numbers, and different styles are frequently printed on them. Printing procedures include display screen printing and warmth switch printing.

- urgent and Shaping: After dyeing and printing, jerseys are pressed and shaped to make certain flatness and aesthetic attraction.

five. Shrinkage Resistance treatment: To save you jerseys from deforming for the duration of washing, shrinkage resistance remedies which includes warmth setting and resin completing are usually carried out to the fabric.

- Environmental-friendly tactics: With the upward thrust of environmental recognition, increasingly more fabrics and tactics are being used in jersey production, which includes formaldehyde-loose dyes and biodegradable substances.

In phrases of cloth selection and manufacturing methods, jersey manufacturing specializes in the following elements:

-

Ergonomics: the selection of fabric and design of the approaches must recollect ergonomic ideas to make sure consolation and freedom of motion whilst carrying the jersey.

-

capability: depending on specific sports activities, the fabric and methods of jerseys should have corresponding functionalities, including breathability, moisture-wicking, and solar safety.

-

Artistry: The design of the jersey need to balance artistry, showcasing the team’s tradition and traits via the usage of cloth and procedures.

In summary, the choice of cloth and the manufacturing system of football jerseys are key to ensuring product fine and performance. every step of the technique wishes to be strictly controlled to make sure the excellence and reliability of the final product.

Design Elements and Innovation

In designing sports uniforms, the integration of various elements and innovative techniques is crucial for enhancing product appeal. Here is a detailed explanation of some specific aspects of uniform design elements and innovation:

In terms of color application, designers select color schemes based on team culture, regional characteristics, and the specific nature of the sport. Bright contrasting colors can enhance the uniform’s recognition, while gradients or mixed colors can add depth and a sense of fashion to the uniform. For example, the classic red and white stripes in football jerseys not only reflect the team’s distinct personality but also meet the visual demands of the playing field.

In pattern design, jerseys often feature basic patterns such as geometric shapes, stripes, and wavy lines, which are simple and easy to recognize. Designers also use complex patterns, abstract designs, or specific graphics (such as team logos, sponsor logos) to strengthen the visual impact of the uniform. For instance, basketball jerseys often incorporate elements of the court lines to create a strong sense of the sports atmosphere.

Material innovation is another key aspect of jersey design. Modern jerseys use high-tech materials like polyester and spandex, which offer excellent breathability, moisture-wicking properties, and elasticity. For example, Nike’s Dri-FIT fabric is widely used in jersey manufacturing, effectively helping athletes stay dry and comfortable.

Functional design is also an important direction for jersey innovation. Modern jerseys often incorporate functional materials such as antibacterial, odor-resistant, and sun-protection elements to enhance the wearing experience. For example, the inner layer of a jersey may be treated with special processes to reduce bacterial growth and maintain cleanliness and hygiene.

Detailing in jersey design focuses on the combination of functionality and innovative craftsmanship. Designs such as removable sleeves, hidden zippers, and adjustable cuffs are not only aesthetically pleasing but also provide convenience during actual sports activities. Additionally, the application of 3D printing technology has brought new possibilities to jersey detail design, such as personalized patterns or enhanced functional features.

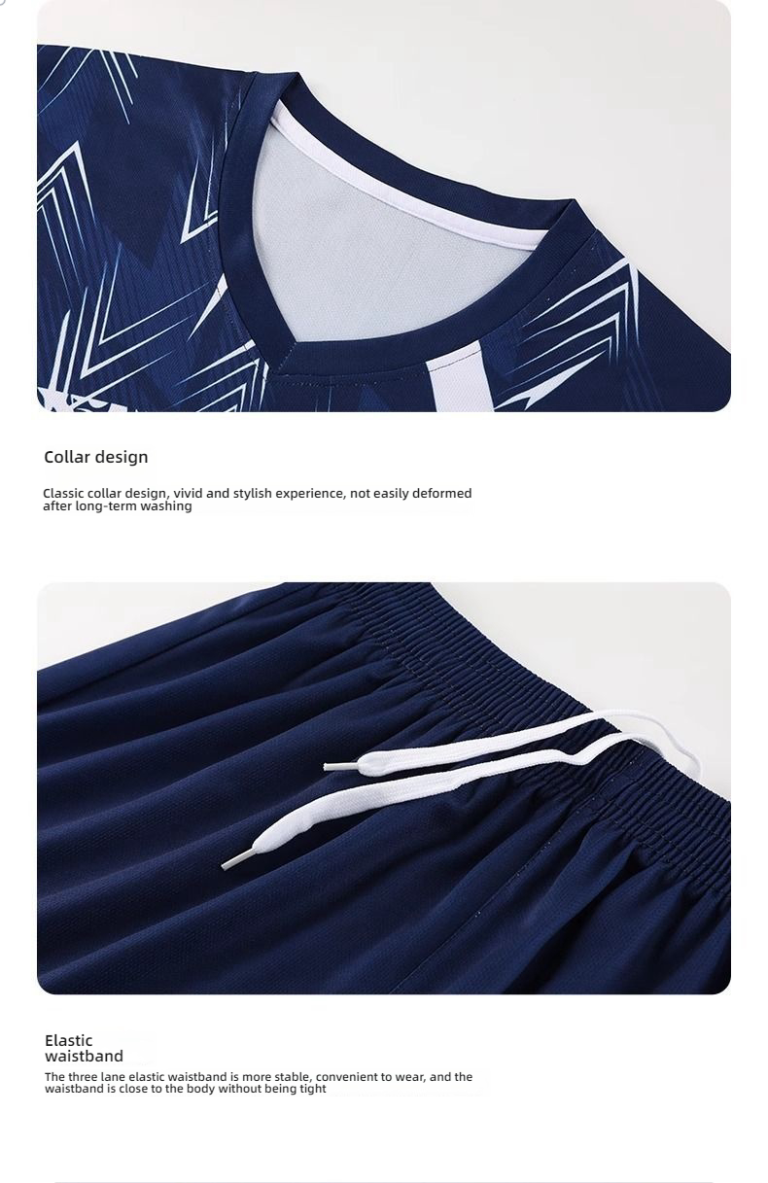

The design of jersey fit is also a key to innovation. Designers adjust the fit of jerseys based on the body types and sports needs of different athletes, ensuring they are both aesthetically pleasing and body-hugging. For example, basketball jerseys are often designed in a slim fit to enhance flexibility and freedom of movement during sports.

While innovating, jersey design also pays attention to the retention of traditional elements. Designers may incorporate the team’s iconic elements into the jersey, such as team colors and emblems, to preserve and promote team culture.

In summary, the design elements and innovation of jerseys are reflected in multiple aspects, including color, pattern, material, functionality, detail handling, and fit design. The comprehensive application of these elements makes the jersey not only a piece of sports equipment but also a cultural symbol and a form of fashion expression.

Manufacturing Process and Quality Control

The fabric, after being reduce, movements into the stitching level. stitching is a vital step within the production of jerseys, concerning tasks which includes joining sleeves, and cuffs. workers ought to make certain that the stitching is even, fending off skipped stitches or breaks, to make sure the sturdiness of the jersey.

once the pieces are stitched collectively, they continue to the trimming and deburring phase. This step calls for meticulous interest, because it includes not most effective reducing off excess threads but also eliminating burrs from the edges of the reduce pieces to prevent pores and skin inflammation for the duration of wear.

subsequent comes the embroidery manner, which requires a excessive stage of talent. The trademarks, sponsor marks, and other patterns at the jerseys need to be precisely embroidered by means of pc embroidery machines, with rich colors and clear designs. After embroidery, the patterns are then heat-set to make sure they may be flat and cozy.

Following that is the washing process for the jerseys. professional gadget is used to clean the jerseys, which eliminates any floating colorings from the manufacturing technique and makes the cloth softer, enhancing the texture of the jersey. The temperature and time at some stage in the washing system have to be managed to save you the cloth from deforming.

The jersey’s coating and printing are key steps to enhance each appearance and overall performance. Coating makes the jersey surface smoother, even as printing adds personalised designs. each coating and printing want to be strictly managed for colour fastness to ensure that the patterns stay colourful after more than one washes.

After all of the methods are whole, the jerseys enter the pleasant inspection stage. This step is critical, as every jersey is very well inspected for sewing, styles, size, and shade. Jerseys that do not meet the requirements are back for reprocessing.

To make sure the scale and suit of the jerseys, a style take a look at is conducted on each batch of merchandise. Testers put on the jerseys to check for consolation, range of movement, and normal suit.

qualified jerseys are then packaged and organized for cargo to the market. The packaging system have to make sure that the jerseys remain uncontaminated and are easy for consumers to become aware of and convey. satisfactory control is ongoing for the duration of the producing process to make certain that the very last product meets enterprise standards.

Market demand and trend analysis

In the selection of fabrics for jersey production, there is a focus on balancing performance and aesthetics. Performance fabrics such as polyester and spandex are widely used due to their excellent breathability, elasticity, and abrasion resistance. The addition of spandex further enhances the stretchability of jerseys, accommodating various athletic poses.

In terms of craftsmanship, jersey manufacturing involves multiple stages, including cutting, sewing, and printing. During cutting, the human engineering design is taken into account to ensure a comfortable fit. In the sewing process, professional machines like overlockers and sewing machines are used to ensure even and sturdy stitching. For printing, technologies such as heat transfer and screen printing are employed to ensure clear and vibrant patterns.

With the advancement of technology, jersey manufacturing processes are also continually innovating. For example, the use of 3D printing technology for jersey production can enable personalized customization of complex patterns, while also reducing the weight of the jersey and improving comfort. Additionally, antibacterial and odor control technologies, as well as smart temperature control materials, are being applied in jersey production to meet consumer demand for health and technology.

The diversity of market demands leads to a rich variety of jersey design styles. From professional sports brands to streetwear brands, jersey design covers a range of styles including sports, leisure, and fashion. In terms of color, from classic black, white, and gray to bright colors, gradients, and color blocking, it satisfies the aesthetic needs of different consumers.

Trend analysis shows that the concept of environmental protection is gaining traction, and green, sustainable production has become an important trend in jersey manufacturing. The use of biodegradable fabrics, reducing the use of chemicals, and optimizing production processes are all driving the jersey industry towards environmental sustainability. At the same time, with the widespread adoption of digital and intelligent technologies, jersey products are also developing towards intelligence and interactivity, such as incorporating sensors and wearable devices to enhance user experience.

Jersey design is increasingly emphasizing cultural heritage and regional characteristics. Many brands incorporate local cultural elements into jerseys, such as city landmarks and traditional patterns, which not only showcase brand identity but also spread regional culture. In jersey design, the combination of sports technology and fashion trends has also become a major trend, such as using high-tech fabrics and combining with popular elements for design, making jerseys functional while also stylish.

Market demand and trend analysis indicate that the jersey industry is heading towards a more personalized and technological direction to meet consumers’ pursuit of high-quality, personalized products.

The status of jerseys in sports culture

The jersey, as a provider of sports activities tradition, holds wealthy symbolic meanings and emotional values. In sports events, the jersey isn’t always best a degree for athletes to show off their style but also a symbol of fans’ emotional investment.

The design of jerseys frequently consists of elements including the crew’s records, subculture, and local characteristics, becoming a image of the crew’s identity. The color combinations and emblem styles of different teams visually create precise identifiability, permitting enthusiasts to immediately understand their desired team. This identifiability now not only enhances lovers’ experience of belonging however additionally makes the jersey an integral part of sports tradition.

The fame of jerseys in sports culture is likewise pondered in their effect on athletes. In competitions, jerseys are not only identifiers of an athlete’s identification however additionally a supply of concept for their perseverance. The numbers on the jerseys represent the placement and function of the athletes inside the group, and their performance on the sector is often closely related to the jersey. moreover, the style and texture of the jersey can have an effect on an athlete’s comfort and performance, and those details are completely considered at some point of the layout and production procedure.

within the field of sports advertising, jerseys are an crucial service for logo collaborations and sponsorships. recognised brands beautify their image and extend their marketplace impact through participating with pinnacle groups on their jerseys. Jerseys function a bridge connecting brands with customers’ emotions, conveying emblem values and product traits through the athletes’ attire.

With the rise of social media, jerseys have additionally emerge as a part of on-line subculture. fanatics proportion their loved jerseys on social media, change team updates, and shape a great virtual community. on this community, jerseys aren’t simply garb; they’re emotional bonds that join fanatics with their groups, in addition to with each different.

The status of jerseys in sports lifestyle is also obvious of their advocacy of sportsmanship and fair competition. In fits, the sponsor trademarks on the jerseys frequently constitute industrial pastimes, but the values of truthful opposition and teamwork conveyed by using the jerseys themselves are the proper embodiment of sportsmanship. The layout and production of jerseys also continuously sell innovation and improvement inside the sports activities enterprise.

The collectible price of jerseys is likewise on the upward thrust. restrained edition jerseys, commemorative jerseys, and other special styles entice numerous fanatics and creditors due to their specific ancient importance and collectible price. those jerseys aren’t simply a part of sports activities tradition but have additionally emerge as hot commodities in the collectibles market.

The position of jerseys in sports lifestyle is multi-dimensional. they are not just the athletes’ equipment but also a provider of the crew, logo, fan emotions, and lifestyle, and a symbol of sportsmanship and values. As sports lifestyle continues to develop and jersey design techniques improve, jerseys will keep to play a considerable position in the future.