Cost-Effective Sports Jerseys: IT, Q, X, and Quality with Affordable Solutions

sports activities jerseys, as an essential product inside the sports industry, have seen a non-stop boom in marketplace demand. even as pursuing nice, cost manage has become a focal point for organisations. this newsletter will delve into how to attain cost discount for sports jerseys thru the optimization of production generation, the enhancement of supply chain performance, and the reference to successful case studies.

Market Overview: Trends in Sports Jersey Market

The sports activities jersey market has shown a consistent boom trend in recent years. With the energetic development of the global sports industry, clients’ demand for personalised and sports garb has multiplied. here are a few key trends in the sports jersey market:

diverse consumer possibilitiesAs fashion merges with sports, consumers have higher demands for the patterns, colours, and materials of sports jerseys. personalised customization has come to be a first-rate fashion, with consumers now not best pursuing purposeful needs but additionally focusing at the style sense and personalised layout of the jerseys.

rise of on-line income ChannelsThe speedy improvement of e-commerce has introduced new growth points to the sports jersey marketplace. the benefit and huge insurance of on-line income channels have attracted a big wide variety of young clients, main to a 12 months-on-yr growth in on-line sales.

Intensified emblem oppositionThe competition amongst brands within the sports jersey marketplace is turning into increasingly fierce. most important brands are making an investment greater in studies and development to decorate product first-rate and are attracting consumers via go-border collaborations and confined version releases to cozy an area in the market.

Environmental attention Deeply RootedThe rise of environmental awareness has caused the combination of sustainable improvement principles in the sports activities jersey marketplace. increasingly manufacturers are using environmentally friendly materials and reducing carbon emissions within the production process to meet purchasers’ demand for green and merchandise.

non-stop increase within the high-give up marketplaceThe high-end sports jersey marketplace continues to develop, with high-give up clients having better necessities for great and performance. manufacturers are meeting the wishes of this section through the use of excessive-tech fabrics, satisfactory craftsmanship, and precise designs.

extensive ability inside the kids marketplaceyoung people are the principle consumers of sports activities jerseys, and they have a excessive stage of loyalty to sports activities brands and are open to trendy designs. consequently, the teens marketplace has grow to be an vital location for sports jersey brands to amplify their commercial enterprise.

sports occasions boost market advertisinglarge-scale sports activities activities provide a herbal platform for promoting the sports jersey marketplace. for the duration of these events, jersey sales regularly enjoy a surge, with brands improving emblem popularity and marketplace share thru event sponsorships and restrained version jersey releases.

move-Border Collaborations as a brand new fashionsports activities jersey manufacturers are no longer restrained to the sports zone and are starting to engage in pass-border collaborations with different industries which includes style and enjoyment. This collaboration not only enriches the product line however additionally brings new market possibilities for manufacturers.

The sports activities jersey market is facing a ramification of demanding situations and opportunities. brands need to keep up with marketplace traits, innovate continuously, and meet the ever-converting demands of purchasers.

Cost Control: Methods to Reduce the Production Costs of Sports Apparel

within the manufacturing technique of sports group jerseys, price control is a vital component. right here are a few effective techniques to lessen the manufacturing expenses of sports team jerseys:

-

Optimize raw material Procurement: via bulk shopping, establishing long-time period partnerships with providers, and selecting fee-effective materials, it is feasible to seriously decrease cloth fees. moreover, strict best manipulate of raw substances can help reduce rework and waste resulting from high-quality problems.

-

improve manufacturing methods: Optimizing manufacturing tactics with the aid of getting rid of unnecessary steps and operations can reduce manufacturing time, thereby decreasing exertions charges. as an instance, using automatic equipment to update some guide operations can growth manufacturing performance.

-

enhance production efficiency: by using training employees to enhance their skills and operational skillability, reduce mistakes and remodel within the manufacturing technique. furthermore, manufacturing schedules to keep away from downtime on production traces is also key to increasing performance and lowering expenses.

-

affordable design: while designing sports activities group jerseys, price factors should be considered. Simplify the design, keep away from complicated strategies, and this may reduce manufacturing costs. at the same time, make reasonable selections of fabric and accessories to make sure the product is each aesthetically eye-catching and value-effective.

-

manipulate Packaging charges: In packaging layout, try and use environmentally pleasant and minimalist packaging strategies to lessen using packaging substances. furthermore, via bulk packaging, reduce the packaging price in line with unit product.

-

improve nice control: Strictly control every component of the manufacturing manner to ensure product excellent. decreasing transform, returns, and after-sales costs caused by fine issues.

-

make use of facts era: undertake ERP, MES, and other statistics management structures to improve manufacturing control performance and reduce management prices. on the same time, via records evaluation, pick out key factors for value manage and optimize them therefore.

-

enlarge sales Channels: by using combining on-line and offline sales channels, expand the marketplace attain and boom income volume, as a result decreasing the unit price of sales.

-

affordable Allocation of Human sources: Allocate human sources in line with production wishes to avoid waste of human sources. additionally, through performance appraisal, encourage personnel to enhance paintings efficiency.

-

stay informed approximately industry Dynamics: maintain a near eye on marketplace trends and competitor situations, and regulate manufacturing strategies in a timely way to reduce manufacturing charges.

via imposing these strategies, sports activities group jersey production agencies can correctly lessen production fees whilst making sure product exceptional, thereby enhancing market competitiveness.

How to choose sports team jerseys with high cost-performance ratio

When selecting sports apparel from the numerous brands and styles available, finding products with good value for money is a key concern for consumers. Here are some key points to help you make wise choices during your purchase:

Material Selection: High-quality fabric is the foundation for comfort and durability. A blend of materials like cotton, polyester, and spandex can provide good breathability and elasticity. Consumers should pay attention to the fabric description on the clothing label and choose materials that are breathable and have low shrinkage rates.

Brand Comparison: Sports apparel from well-known brands can be more expensive, but they offer guaranteed quality and after-sales service. However, there are also many affordable domestic brands on the market that are on par with imported brands in terms of design and quality, but at more affordable prices. Consumers can compare different brands’ styles, designs, fabrics, and prices to find products with good value for money.

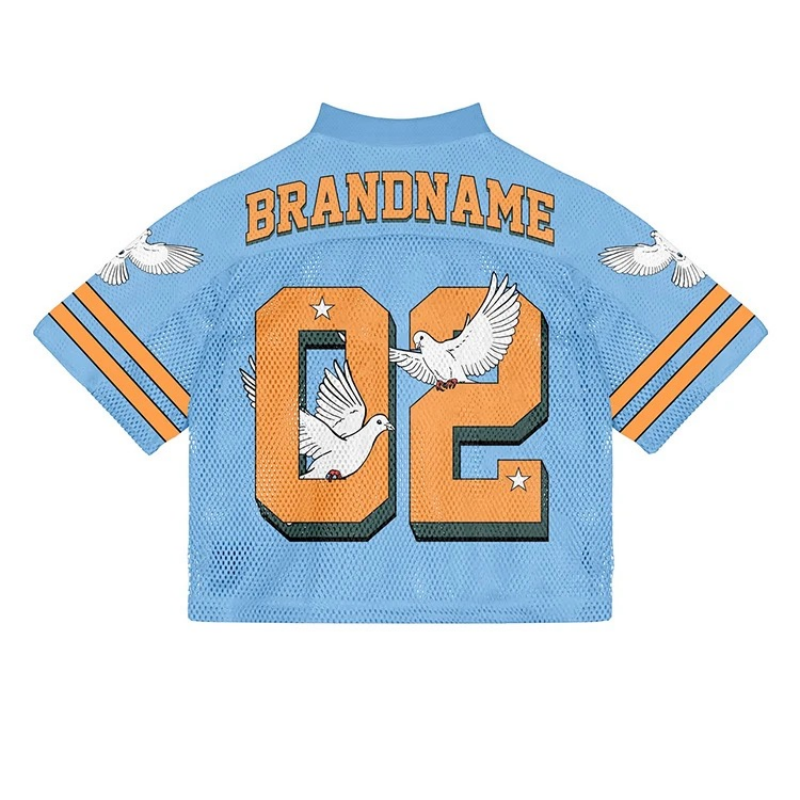

Style and Design: Fashionable designs and personalized elements can enhance the appeal of sports apparel. While focusing on style, practicality should also be considered. For example, whether the fit of the jersey is comfortable, if there are enough pockets for personal items, and if there are reflective strips for safety features.

Color and Pattern: Bright colors and unique patterns in sports apparel are often more popular, but this may also increase costs. Consumers should choose colors and patterns based on their preferences and needs. At the same time, simple-designed jerseys, although not expensive, can also have good visual appeal.

After-sales Service: When purchasing sports apparel, after-sales service is also a factor not to be overlooked. Good after-sales service ensures that consumers can get timely solutions if there are any issues with the jersey. Consumers can check the brand’s official website or consult customer service to understand their return and exchange policies, repair services, and other information.

Price Comparison: Price is an important consideration when buying sports apparel. Consumers can compare prices online, take part in promotional activities, and purchase desired products at lower prices. At the same time, be careful to avoid traps of low prices and ensure the quality of the product purchased.

Market Research: Keeping an eye on market trends and understanding current popular sports apparel styles and prices can help consumers make more informed purchasing decisions. Consumers can obtain the latest market information through social media, e-commerce platforms, sports goods stores, and other channels.

By considering these factors—material, brand, style, design, color, pattern, after-sales service, price, and market research—consumers can select sports apparel that offers good value for money. Remember, what suits you best is the best, and you should not blindly pursue brands or prices, but rather make choices based on your actual needs.

Craft Technology: Key Techniques and Cost Impacts in the Production of Football Shirts

The choice of process technologies in the production of sports team jerseys directly affects both costs and product quality. The following descriptions outline several key process technologies and their impact on costs:

-

Fabric Selection: The fabric used for sports team jerseys is a significant factor in determining cost. High-quality fabrics such as polyester and nylon are more expensive but offer good durability and moisture-wicking capabilities. Lower-cost fabrics like cotton or recycled fibers are cheaper but may lack in durability and functionality. Producers need to find a balance between fabric cost and performance.

-

Printing and Embroidery Techniques: Team names, numbers, and sponsor logos on jerseys are typically applied using printing or embroidery techniques. Printing is cost-effective and suitable for large-scale production, but has relatively lower durability. Embroidery, however, is more expensive but provides clear graphics and is wash-resistant, making it ideal for high-end products. Choosing the appropriate printing or embroidery technique based on product positioning and market demand can significantly affect costs.

-

Seaming Techniques: Seaming is a fundamental part of jersey production, including stitching and hemming. Automated sewing machines can greatly increase production efficiency and reduce labor costs, but require a higher initial investment. Hand sewing is time-consuming but ensures higher quality, which is suitable for customized production or small batch orders.

-

Post-Processing Techniques: After production, jerseys often require post-processing, such as ironing, creasing, and anti-wrinkle treatments. These processes can enhance the final appearance and feel of the jersey but also increase costs. For example, using environmentally friendly anti-wrinkle agents can raise costs but provide a more durable anti-wrinkle effect.

-

Pattern Design: The pattern design of jerseys directly affects the comfort and aesthetics of the finished product. Advanced pattern designs require professional designers and are costly. However, reasonable design can enhance product competitiveness and, in the long run, positively impact brand image and sales.

-

Quality Management: Rigorous quality management is crucial for cost control. Implementing Total Quality Management (TQM) and Six Sigma quality methods can reduce defect rates and lower rework costs. Regular quality checks and equipment maintenance are also important for ensuring cost control.

-

Packaging and Logistics: The costs associated with packaging and logistics should not be overlooked. Choosing environmentally friendly and cost-effective packaging materials can reduce costs. Additionally, optimizing logistics processes and reducing transportation losses can also effectively control costs.

By selecting and optimizing these process technologies, sports jersey manufacturers can control costs while ensuring product quality, thereby improving the cost-performance ratio of their products.

Supply Chain Optimization: Strategies to Enhance Efficiency in Sports Jersey Production

inside the production technique of sports jerseys, the optimization of the deliver chain is the key to enhancing efficiency. the subsequent are specific techniques to enhance the manufacturing performance of sports jerseys:

-

Centralized Procurement approach: with the aid of centralizing the procurement of raw materials along with fabric and stitching threads, bulk reductions may be secured, decreasing unit costs. additionally, centralized procurement allows to lessen the number of providers, simplifying deliver chain control, and decreasing time and logistics fees in the procurement procedure.

-

supplier selection and management: deciding on providers with excellent reputation and stable supply capabilities is crucial for ensuring production performance. organising long-time period and solid partnerships can reduce downtime and delays caused by dealer problems. moreover, ordinary evaluation of suppliers ensures their manufacturing capacity and product nice meet requirements.

three. manufacturing system Optimization: conduct a detailed evaluation of the production process to identify bottleneck ranges and reengineer the process. as an example, improving slicing techniques can reduce waste, and optimizing sewing tactics can decorate velocity and excellent.

- Automation and Intelligentization: Introducing automated equipment such as pc cutting beds and automatic sewing machines can extensively boom production performance. meanwhile, the software of sensible structures, which includes the usage of records series and analysis to are expecting call for, can lessen stock overstock and enhance reaction velocity.

five. Logistics and Warehouse control: Optimize logistics distribution to reduce transportation time and charges. adopt superior warehouse management systems to acquire real-time tracking and unique control of inventory, lowering inventory losses and exertions prices.

-

employee training and Incentives: regularly educate employees to enhance their operational proficiency and hassle-solving abilities. moreover, establish powerful incentive mechanisms to inspire employees to enhance paintings performance and quality.

-

exceptional manipulate and remarks: establish a strict first-rate control device to investigate each stage from uncooked substances to finished products. promptly comments on substandard products, examine the reasons, and take measures to prevent recurrence of issues.

eight. Environmental protection and Sustainability: focus on environmental protection in the production system, the usage of environmentally pleasant substances and technology, and lowering environmental effect. on the equal time, promote sustainable production standards to improve aid utilization performance.

-

statistics generation application: make use of facts technology structures which includes ERP and MES to acquire real-time sharing and collaboration of production, stock, and sales information, improving decision-making performance.

-

marketplace response velocity: closely music market tendencies and fast respond to client demands to shorten the time from product design to marketplace release, enhancing marketplace competitiveness.

via enforcing those strategies, it may correctly improve the manufacturing efficiency of sports activities jerseys, lessen expenses, and enhance the marketplace competitiveness of the organisation.

Case Study: Experience Sharing by a Successful Sports Jersey Manufacturer in Cost Reduction

In the field of sports jersey manufacturing, cost control is crucial. A well-known manufacturer has successfully reduced production costs through the following strategies:

-

Optimized Raw Material Procurement: The manufacturer has established long-term cooperative relationships with multiple suppliers, achieving bulk procurement of raw materials to lower unit costs. At the same time, by comparing quotations and quality from different suppliers, they have chosen materials with higher cost-effectiveness, ensuring the durability and aesthetics of the jerseys.

-

Production Process Optimization: The manufacturer has meticulously analyzed the production process, improving it to reduce unnecessary steps and waste. For example, through optimized cutting techniques, they have reduced fabric wastage; and by adopting automated equipment, they have increased production efficiency and reduced labor costs.

-

Strict Quality Control: The manufacturer has established a rigorous quality control system, conducting strict quality inspections at each stage from raw material procurement to finished product shipment. By reducing the rate of defective products, they have lowered costs associated with rework and waste disposal.

-

Investment in Technology Upgrade: To enhance production efficiency and reduce costs, the manufacturer continuously invests in the introduction of new technologies and equipment. For instance, they have introduced advanced sewing machines to improve production speed and accuracy; and have adopted environmentally friendly dyes to reduce pollution during production and post-processing costs.

-

Optimized Logistics Management: In logistics management, the manufacturer has achieved cost reductions through close cooperation with logistics partners. By optimizing transportation routes and reducing transit times, they have lowered logistics costs.

-

Employee Training and Incentives: The manufacturer emphasizes employee training and development, conducting regular skill training to enhance work efficiency. They also implement incentive policies to encourage employees to propose improvement suggestions, fostering a shared commitment to cost control.

-

Market Analysis and Product Innovation: The manufacturer closely monitors market trends and innovates products based on consumer demand. By introducing new styles that align with market trends, they have increased product competitiveness and also reduced the risk of inventory overstock.

-

Collaborative Supply Chain Management for Win-Win: The manufacturer has established close relationships with upstream and downstream suppliers, sharing market information, technology resources, and profits. This cooperative model helps reduce supply chain costs and improve overall competitiveness.

Through these strategies, the manufacturer has successfully reduced the production costs of sports jerseys while maintaining product quality, enhancing market competitiveness. Their experience provides valuable lessons for the industry.