Exploring the Football Sports Jersey Industry: Quality, Innovation, and Customization Trends

within the global of soccer, the group jersey isn’t always simply the uniform of the gamers, however additionally a symbol of group culture and fan sentiment. The manufacturing unit, as an indispensable part of this specific subculture, embodies the heartbeat of the industry in terms of manufacturing technology, fabric choice, customization services, and market packages. this article delves into the modern-day country of the soccer sports garb enterprise, analyzes its traits and demanding situations.

Overview of a Jersey Factory

The football jersey factory, located in an industrial area of our country, boasts a vast area and is a professional manufacturer of football sports equipment, integrating design, production, and sales. Since its establishment, the factory has always adhered to the philosophy of “Quality First, Service as the Core” and is committed to providing high-quality football jerseys to customers both domestically and internationally.

Equipped with advanced production equipment and introducing world-class garment-making technology, the factory ensures that every jersey meets strict quality standards. From material selection to finished product dispatch, every process is strictly controlled, striving to create classic works of football sports attire.

The production line of the factory is divided into several stages, including cutting, sewing, pressing, and quality inspection, each stage being handled by experienced professionals. The cutting stage uses computer-controlled cutting beds for high precision and reduced material waste; the sewing stage employs high-speed flat-seaming machines to ensure even and durable stitching; the pressing stage utilizes professional pressing equipment to guarantee the flatness of the jerseys; and the quality inspection stage is strictly supervised by a dedicated quality control team to ensure there are no defects in the products.

In terms of material selection, the factory rigorously selects high-quality fabrics such as breathable polyester and wear-resistant nylon, combined with professional design, making the jerseys not only stylish but also functionally excellent. Moreover, the factory also pays attention to environmental protection, using biodegradable dyes and accessories to minimize environmental impact.

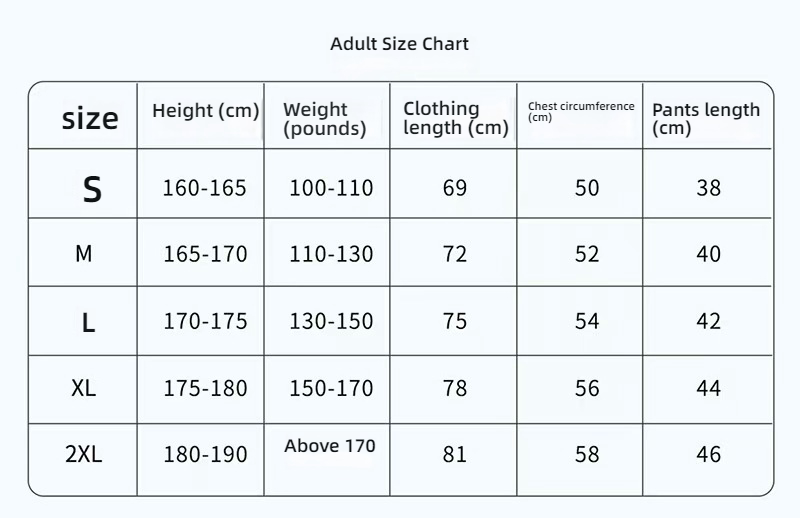

To meet the diverse needs of customers, the factory offers personalized customization services. From colors and patterns to sizes, customers can customize according to their preferences. This service is applicable not only to professional teams but also to amateur teams, school football teams, and others, catering to the needs of customers of various scales and types.

With the popularization of football and the continuous expansion of the sports market, the market application of the jersey factory has become increasingly widespread. In addition to football, the factory’s products are also used in various sports such as basketball, volleyball, and track and field, becoming the preferred choice for various sports teams and individuals.

Faced with industry development, the jersey factory continuously innovates in technology and upgrades its products to meet market changes and customer needs. At the same time, the factory actively responds to challenges such as rising raw material prices and increased environmental protection requirements, ensuring the sustainable and healthy development of the enterprise through optimized supply chains and improved production efficiency.

With its professional production team, strict quality control, and diverse product lines, the jersey factory stands out in the fierce market competition and has become an outstanding player in the domestic football sports equipment field. In the future, the factory will continue to adhere to its original intentions, providing customers with better products and services, and contributing to the development of the sports cause.

Process Production Analysis

In the production process of team jerseys, every step is crucial. Here is a detailed breakdown of the jersey manufacturing process:

Accurate Cutting: Advanced laser cutting or computer-assisted cutting technology is used to ensure precision in fabric cutting, reducing waste, and improving material utilization.

Dyeing Process: According to different color requirements, eco-friendly dyes are used for dyeing to ensure even color distribution, washability, and UV resistance, while minimizing environmental impact.

Printing Techniques: Silk screen printing, thermal transfer, or direct inkjet printing techniques are employed to precisely print logos, numbers, brand logos, and other patterns onto the jerseys, ensuring clear and vivid imagery.

Seaming Process: Professional sewing machines are used for stitching to ensure even and sturdy seams, avoiding damage due to poor stitching.

Collar and Cuff Treatment: Special treatments are applied to areas prone to wear, such as collars and cuffs, using elastic fabrics or reinforced stitching to increase durability.

Functional Treatment: Functional treatments are applied to the jerseys based on sports requirements, such as using breathable fabrics and sweat-wicking properties to enhance comfort.

Final Inspection: After production, each jersey undergoes strict quality inspection, including size, color, pattern, and stitching, to ensure the product meets standards.

Packaging and Logistics: Qualified products are packaged to ensure they are not damaged during transportation and are dispatched according to order specifications.

Throughout the production process, jersey factories emphasize environmental protection and sustainability, using biodegradable materials, reducing energy consumption and waste emissions during production. Additionally, factories continuously introduce new technologies and equipment to improve production efficiency and product quality to meet market demands.

Material Selection and Quality Assurance

inside the system of manufacturing soccer fit jerseys, material choice and first-rate warranty are critical factors. the following is an in depth description of those factors:

material: The jersey material is the foundation that comes into direct contact with the athlete’s skin, so its first-class immediately influences the player’s comfort and overall performance. jerseys usually use substances with proper breathability and moisture-wicking talents, inclusive of synthetic fibers like polyester (Polyester), spandex (Spandex), and nylon (Nylon). these substances are characterised by way of their sturdiness and resistance to deformation. some manufacturers also use high-tech fabric, which includes unique fibers with antibacterial and scent-resistant residences, to decorate the longevity and functionality of the jersey.

stitching method: stitching is a important step in jersey production, which without delay affects the jersey’s sturdiness and appearance. professional jersey factories generally hire double-needle sewing to make certain even and at ease stitching. further, fine strategies which include hemming and binding can increase the sturdiness of the jersey, stopping the publicity of thread ends. at some point of the assembly technique, factories strictly manipulate the junction points to make certain that seams are flat and do now not show off any fraying.

colour and pattern: The coloration and pattern design of the jersey also are part of the excellent warranty. To make certain vibrant and sturdy shades, factories use dyes which are proof against mild and washing. patterns are processed through strategies inclusive of warmness transfer, embroidery, and display screen printing, which guarantee clean and fade-resistant designs. In sample design, factories additionally don’t forget the durability and comfort of the jersey, averting overly complex styles that might have an effect on the jersey’s breathability.

protection standards: safety requirements are of paramount significance within the jersey production process. Factories produce strictly in accordance with FIFA and the policies of various sports activities organizations to make sure that jerseys meet size standards, weight limits, and material protection. for instance, the scale of the breathable holes, collar, and sleeve designs ought to follow ergonomics to make certain that athletes are not limited at some stage in competition.

Inspection and Certification: After the jersey is produced, factories behavior rigorous internal high-quality assessments, together with inspections of size, color, pattern, and stitching. some brands also entrust 1⁄3-party checking out establishments for certification to ensure that jerseys meet global standards. through those inspections and certifications, the best of the very last product can be assured.

Environmental safety and Sustainability: With the upward push of environmental focus, jersey factories are an increasing number of specializing in the choice of environmentally pleasant substances and measures within the manufacturing process. This consists of using recyclable substances, lowering using chemical substances, and optimizing production strategies, all aimed at reducing the effect on the surroundings even as ensuring product first-class and sustainability.

Customized Services and Market Applications

The jersey factory gives a diverse range of customization offerings even as catering to personalized desires. beneath is a detailed description of this service and its marketplace packages:

the choice of fabric is significant, ranging from distinctly breathable polyester to heat wool blends, and even recycled materials. customers can pick the maximum suitable cloth based totally at the group’s characteristics, climate conditions, and personal preferences.

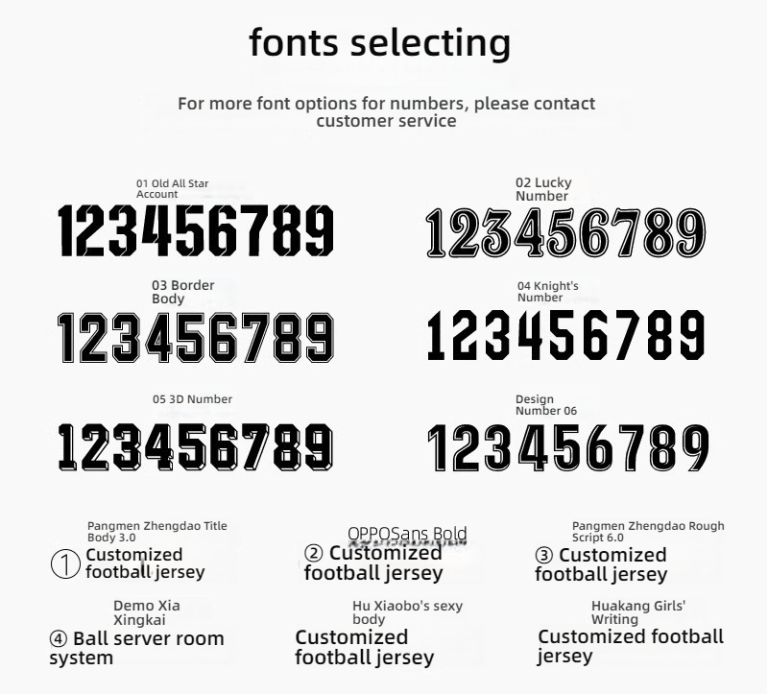

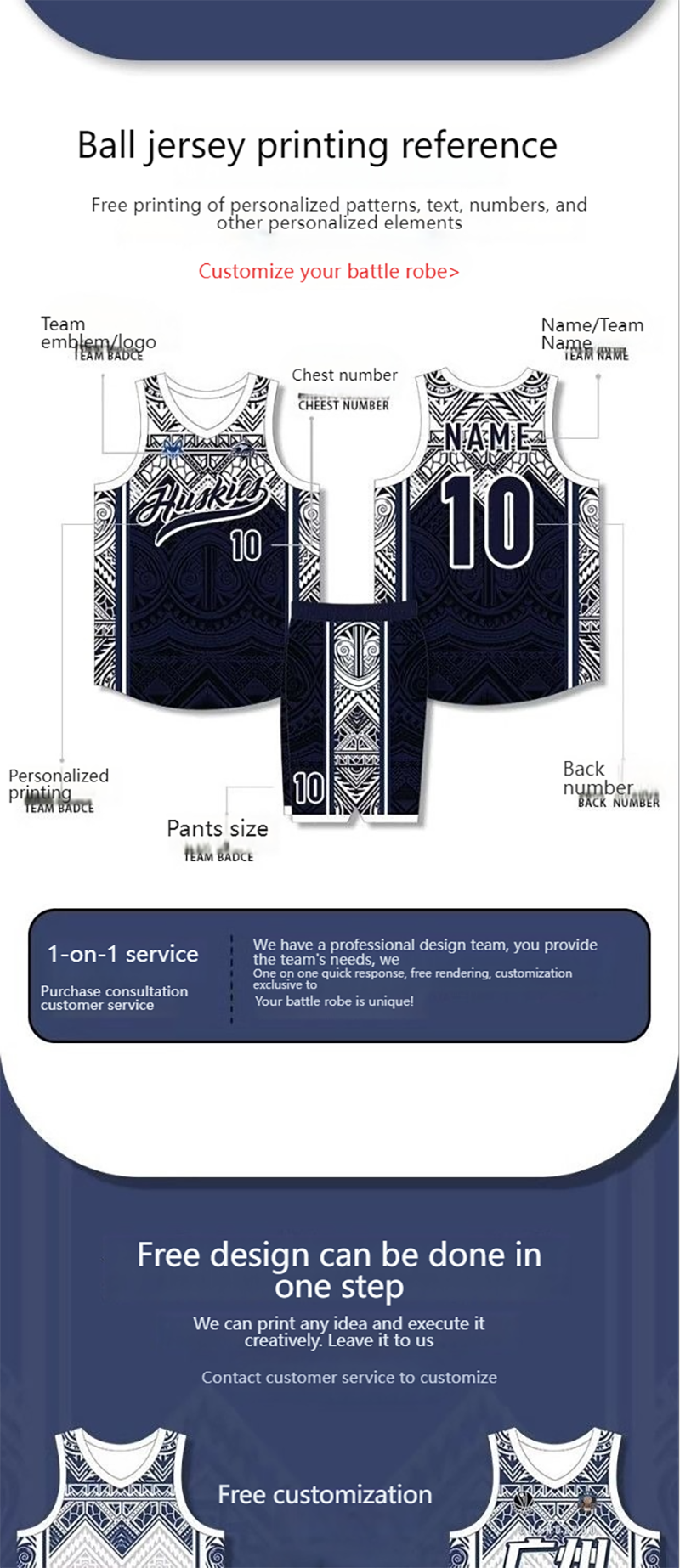

In phrases of sample design, the factory is ready with a expert design team that can create particular patterns based totally on the purchaser’s provided emblems, group names, and sponsor logos. additionally, customers can freely mix and fit shades, fonts, and patterns to create a completely unique jersey.

In phrases of expertise, the jersey manufacturing unit utilizes advanced digital printing era to make sure clean styles, vibrant colours, and resistance to fading. The manufacturing facility additionally affords services for unique system requirements on customized initiatives, such as embroidery and warmth switch.

In phrases of market packages, customized jerseys are not handiest appropriate for expert football golf equipment however are also broadly used by newbie teams, school sports activities groups, corporate groups, and various sports activities activities. here are some precise utility eventualities:

-

expert clubs: top football golf equipment often pick out to collaborate with the jersey factory while changing jerseys for the duration of the season to make sure well timed transport and nice assurance.

-

college sports groups: school sports activities groups customise exceptional jerseys for competitions or college anniversary events to beautify crew cohesion and college satisfaction.

three. corporate groups: agencies frequently customize jerseys with the agency logo to beautify logo image, for use in corporate occasions, sports activities competitions, or group-building activities.

four. sports events: numerous sports events, such as marathons and biking races, frequently provide customized jersey offerings to allow contributors to wear unified apparel, including professionalism and spectacle to the event.

- network clubs: network sports clubs offer custom designed jerseys to attract greater members, facilitating the employer of numerous sports activities activities and promoting the improvement of network sports lifestyle.

through these customization offerings, the jersey manufacturing facility not best meets the wishes of various patron organizations but also brings more energy to the market. driven via high-quality and innovation, custom designed jersey services are increasingly more turning into a highlight inside the sports activities marketplace.

Industry Trend and Challenges

material upgrades, era integration, and the shift towards excessive-quit jersey manufacturingextended environmental focus, the growing fashion of sustainable materials usagegrowing personalized demand, expanding market barriers with customized servicesTechnological innovation drives, wise manufacturing boosts manufacturing performanceinternational market enlargement, intensified brand opposition, neighborhood manufacturers searching for breakthroughsEmergence of digital advertising and marketing, expansion of on-line sales channels for jersey marketssports sponsorship collaborations, a win-win for brand affect and jersey incomeclient attitude shift, capability and fashion coexist as the new fashion

Certainly, here is the translation:”Please carefully check the translated content to ensure no simplified Chinese remains.”

inside the sports items enterprise, football jerseys serve as a carrier of logo image and group spirit, with their design and manufacturing procedure embodying wealthy generation and craftsmanship. With the diversification of market demands, customized offerings have emerged to satisfy the personalised desires of various patron agencies. below is an in depth description of football jersey customization services and their marketplace applications:

In terms of customization offerings, the jersey manufacturing unit offers a full-variety of services from layout to finished products. The layout team creates unique designs based totally at the factors supplied by the customer, along with crew emblems, shade alternatives, and unique styles. In phrases of cloth choice, polyester, spandex, and different materials are used to make certain the consolation and sturdiness of the jerseys. furthermore, the manufacturing unit offers a ramification of jersey styles, consisting of short-sleeve, lengthy-sleeve, tight, and unfastened, to cater to one-of-a-kind weather situations and personal choices of athletes.

The market programs are sizable, with soccer jerseys not restrained to professional clubs and amateur teams, but additionally including college, company, and community enterprise activities. In professional leagues, jersey sponsors collaborate with golf equipment to print brand trademarks and sponsor data at the jerseys, accomplishing logo exposure. In newbie competitions, custom designed jerseys come to be symbols of team concord and a feel of honor. company customers use custom designed jerseys as employee blessings or for corporate image show, improving worker belonging and the social impact of the organization.

With the improvement of digital generation, jersey customization services have additionally moved toward intelligence. via on-line structures, customers can without problems add layout drafts, preview the effects in real-time, and make changes primarily based on comments. This handy carrier version no longer only improves performance however additionally reduces communique expenses for customers. at the same time, customized customization services meet clients’ pursuit of forte, making every jersey precise in its own right.

confronted with fierce market competition and ever-converting patron demands, the football jersey industry is likewise facing many challenges. On one hand, factors which includes fluctuations in uncooked material costs and expanded environmental safety requirements are putting pressure on manufacturing fees; on the other hand, consumers’ requirements for product satisfactory and layout have become increasingly more stringent, demanding that factories ensure exceptional whilst innovating in design. additionally, with the upward push of e-trade, opposition in on line sales channels is turning into increasingly extreme, and traditional jersey factories need to boost up digital transformation to decorate logo have an impact on and market competitiveness.

in the method of responding to challenges, the football jersey industry is growing in several instructions: first, strengthening cooperation alongside the economic chain to obtain resource sharing and complementary benefits; second, growing studies and improvement investment to expand new environmentally friendly substances and decorate product fee-brought; third, expanding on line and offline income channels to beautify brand reputation and marketplace proportion; and fourth, that specialize in expertise cultivation to create a professional group that is familiar with both design and the marketplace.

The soccer jersey industry is displaying a vast prospect in customization offerings and market applications, but it additionally needs to constantly reply to challenges to evolve to marketplace adjustments and consumer needs. via technological innovation, brand building, and marketplace growth, the football jersey enterprise is predicted to reap sustainable improvement.