Jersey 40 Suit: The Perfect Choice for Professional Soccer Jerseys

inside the realm of sports competition, the jersey is not most effective the attire of athletes but also a good sized provider of emblem photograph and man or woman expression. this newsletter will delve into the customization method of jerseys and discuss their programs and impacts in numerous markets.

Overview of Shirt Production

The manufacturing of sports garb, specially soccer jerseys, entails a couple of ranges from raw material selection to finished product delivery. each step calls for strict manage to make sure the final product meets the needs of athletes. beneath is a quick assessment of the manufacturing process.

The production of football jerseys starts offevolved with the procurement of raw materials. jerseys generally use breathable, durable, and washer-friendly synthetic fibers or natural fabric, consisting of polyester and spandex. these materials are difficulty to rigorous choice to make certain they meet environmental and performance requirements.

The fabric is then cut into the various parts of the jersey. This step requires unique slicing gadget to make sure every piece of fabric suits the human engineering design. After reducing, the material undergoes pre-shrinking remedy to limit size changes at some stage in next processing.

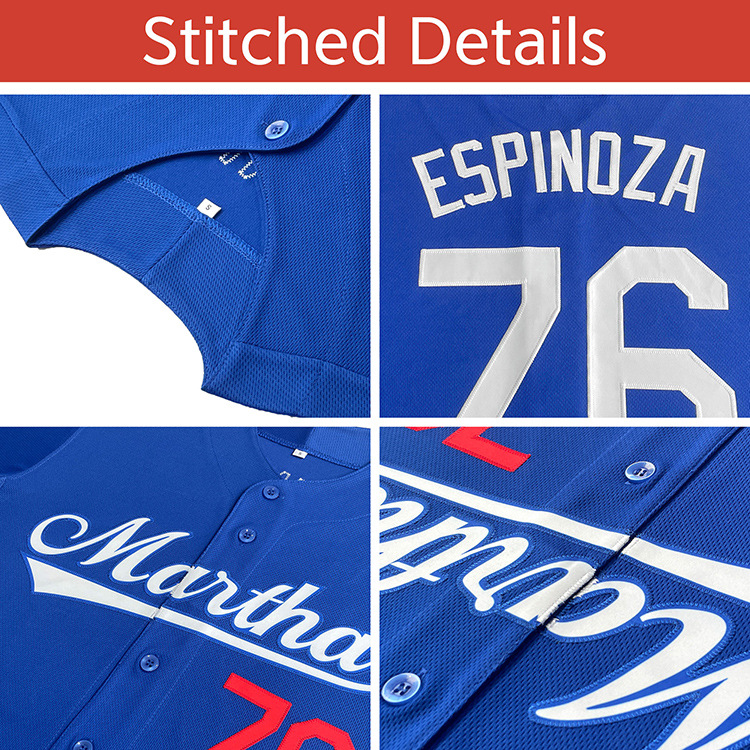

subsequent comes the essential level of meeting and sewing. professional employees use precision sewing machines to sew the one of a kind elements of the jersey together according to the design patterns. the choice of thread, the density of the stitching, and the uniformity of the stitching all at once affect the durability and look of the jersey.

Following this, the jersey moves into the printing and decoration phase. depending on client requirements, the jersey will characteristic team names, numbers, sponsor trademarks, and other decorations. Printing strategies encompass warmth transfer, display screen printing, pad printing, and greater, each with its very own variety of packages and characteristics. ornamental factors along with sequins and embroidery also are finished on specialised gadget.

Internally, designers create one-of-a-kind useful areas based totally on the traits of the sport. those include bolstered shoulders and breathable vests, amongst others. these practical designs not simplest enhance consolation however additionally improve athletic performance.

The sizing and fitting design of the jersey are critical. via human measurement statistics and sporting enjoy, designers can ensure that the jersey suits nicely and is aesthetically beautiful. additionally, jersey size specs need to be adjusted according to exclusive national and regional standards.

satisfactory manage and inspection are vital levels in which each jersey undergoes thorough exams. This includes appearance inspections, useful checks, and size measurements to make certain each jersey meets satisfactory requirements.

sooner or later, the packaging stage entails packaging the jerseys according to purchaser requirements, whether it’s man or woman packaging, set packaging, or present container packaging. Packaging layout must reflect the emblem photo whilst also considering ease of transportation and storage.

In precis, the production of soccer jerseys is a complex and meticulous manner. From the selection of uncooked substances to the completed product, every step requires careful coping with to make certain that the very last product meets the wishes of athletes and showcases the emblem’s professionalism and high high-quality.

Jersey 40 material characteristics

Jersey forty is a sports jersey cloth with the subsequent distinct capabilities:

The fiber composition generally consists of polyester fabric, which boasts superb put on resistance and guarantees that the jersey continues appropriate elasticity and durability regardless of frequent put on.

The density of Jersey forty is mild, which ensures the material’s breathability even as additionally improving its thermal insulation. This density offers an excellent match all through motion without overly limiting the athlete’s moves.

The cloth’s knitting procedure capabilities a fine single jersey weave, which makes the jersey surface smooth and secure to wear, even as additionally helping in sweat evaporation to maintain the athlete dry.

Jersey forty boasts vibrant colours that are immune to fading, making it appropriate for printing diverse patterns and crew trademarks, which is giant for reinforcing the jersey’s aesthetics and logo photo.

The fabric has excellent wrinkle resistance, permitting the jersey to quick return to its unique shape after more than one washes and folds, preserving a flat appearance.

In terms of UV protection, Jersey 40 correctly blocks some ultraviolet rays, supplying athletes with a certain diploma of solar safety.

because of the homes of the polyester material, Jersey forty well-knownshows precise chemical resistance and isn’t without difficulty broken via commonplace detergents and disinfectants.

the burden of Jersey forty is light, making it easy to hold and shop, that is especially vital for athletes who need to frequently exchange their jerseys.

The environmental performance of Jersey 40 has also been advanced, with its production process lowering environmental pollution and meeting the requirements of present day sustainable development.

Process Technology Analysis

The technique of creating a jersey entails more than one delicate steps, and here is an in depth breakdown of the manufacturing manner for the Jersey forty:

fabric treatment: earlier than the formal production, the Jersey forty material undergoes a pre-shrinking treatment to minimize shrinkage inside the finished product at some stage in use. This step is completed via excessive-temperature and excessive-pressure processing to make certain the material continues its length stability all through next washing and wearing.

slicing: reducing is the muse of jersey manufacturing. people use laser slicing or conventional scissors to reduce the cloth consistent with the jersey template. Laser reducing gives better precision, reduces fabric waste, and improves manufacturing performance.

stitching: stitching is a crucial a part of jersey manufacturing, together with front, sleeve hem, and collar, amongst others. professional stitching machines, such as high-velocity flat stitching machines, are used to ensure even and robust stitching. For greater complex designs, such as mesh sections, unique stitching techniques like overlock stitching may be required to keep the cloth’s appearance and sturdiness.

Lockstitching and ornament: After stitching, the rims of the jersey are locked to prevent fraying. This step may be finished the usage of warmth-sealing machines or via hand. moreover, ornamental elements on the jersey, including emblem logos, numbers, and team trademarks, are constant the use of strategies like warmness switch, embroidery, or pad printing.

urgent: To reap a flat and aesthetically appealing jersey, each piece is pressed after crowning glory. urgent now not best makes the garment extra crisp however also eliminates wrinkles, making sure the jersey’s appearance best.

excellent Inspection: There are strict best inspections at each degree of the jersey production method. From cloth to finished product, every jersey is going via a couple of first-class tests, such as size, stitching, and ornamental information, to make sure compliance with great standards.

Packaging: qualified jerseys go through very last packaging. at some point of the packaging manner, suitable packaging substances are chosen based on consumer requirements, which includes plastic baggage or cardboard packing containers, to make sure the jerseys aren’t broken all through transportation.

Environmental protection: With the rise of environmental recognition, jersey manufacturing also focuses on sustainability. a few producers use biodegradable substances to lessen environmental effect.

The above is an in depth clarification of the manufacturing manner for the Jersey 40, with each step reflecting a focal point on detail and a pursuit of product exceptional.

The sizing and slicing process of jerseys are critical for making sure consolation and uniform appearance. beneath is a detailed evaluation of this manner:

-

dimension: earlier than the production of jerseys, distinctive measurements of the gamers are taken. This includes the chest circumference, shoulder width, body period, and sleeve length, among different key regions. distinct manufacturers and patterns may have various measurement requirements, but they usually discuss with internationally identified size standards.

-

length selection: based on the dimension consequences, the best length is selected in conjunction with the participant’s top, body kind, and sports requirements. Jersey sizes typically variety from S, M, L, XL, and a few brands offer XXL and large sizes.

-

cutting Templates: A cutting template is made consistent with the chosen size. Templates are usually manufactured from cardboard or plastic and might correctly reflect the size of the jersey’s numerous parts.

-

slicing process: The cutting template is positioned at the jersey material, and the outline is cut in keeping with the template. interest is paid to the course of the material to keep away from dimensional errors resulting from the cloth’s texture.

-

Shoulder and Sleeve Connection: After the reducing is complete, the shoulder and sleeve components are connected. This step requires particular alignment to ensure the jersey’s shoulder lines are smooth and the sleeve openings are correctly sized.

-

Collar Processing: The collar is an critical a part of the jersey, and its slicing and sewing immediately affect the jersey’s consolation. The collar cutting need to make certain a neat line, and the sewing have to pay attention to the peak and tightness of the collar.

-

ornamental elements cutting: decorative elements at the jersey, such as group logos, sponsor trademarks, etc., also want to be cut as it should be consistent with the layout drawings. the location and size of those factors at once affect the overall aesthetics of the jersey.

eight. becoming Adjustment: After the reducing is entire, the jersey is attempted on the player to test the fit. If vital, minor adjustments are made to the frame duration and sleeve duration.

nine. sewing method: After the cutting and becoming modifications are correct, the jersey moves into the stitching section. sewing strategies consist of stitching, part locking, ironing, and so forth., to make sure the jersey’s durability and aesthetics.

- nice Inspection: After the stitching is complete, the jersey undergoes great inspection. This consists of checking the integrity of the stitching, alignment of decorative elements, comfort of the collar and sleeve openings, and greater.

through those steps, the sizing and cutting of jerseys are exactly finished, making sure that every participant can put on a properly-fitted, comfortable, and aesthetically captivating jersey.

Printing and Decoration Techniques

In phrases of print generation, the ornamental aspects of football jerseys are frequently:

-

colour Matching: soccer jerseys provide a rich form of coloration alternatives for prints. Designers skillfully fit shades in keeping with crew colorations or non-public choices, developing visually putting patterns. Brightly colored prints beautify the fashionability of the jersey and increase recognition at some point of games.

-

sample design: The range of print styles is diverse, together with crew emblems, sponsor trademarks, historical elements of the crew, geometric shapes, and summary styles. The layout of the patterns ought to align with the general style of the jersey while considering each performance and aesthetics.

three. Print Positioning: the choice of print function is critical for the overall effect of the jersey. commonplace print positions encompass the front, again, sleeves, and collar. relying at the design requirements, prints can be concentrated in a single vicinity or dispersed across a couple of places to create a sense of intensity.

four. Printing techniques:

a. Water switch Printing: using water strain to into the cloth, forming the sample. Water switch printing is characterised by a good feel, brilliant colorings, and resistance to fading.

b. screen Printing: moving dye to the fabric thru a display printing device to shape the pattern. screen printing is suitable for complex styles but may additionally have troubles with a tougher sense and much less colourful colorations.

c. warmth switch Printing: Printing the pattern on transfer paper after which transferring it to the jersey via excessive-temperature heating. heat switch printing is suitable for diverse fabrics, supplying clean styles and rich colorations.

d. Embroidery Printing: using threads to stitch the pattern onto the jersey, creating a 3-dimensional effect. Embroidery is suitable for factors which include group trademarks and team names.

-

durability: the printed jersey ought to have proper washability, sunfastness, and abrasion resistance to ensure that the sample stays clear after multiple washes and day by day use.

-

exceptional manipulate: all through the printing manner, strict manage over dye fine, printing strategies, and equipment precision is important to make sure the expected print impact. moreover, great inspections of the broadcast jerseys are conducted to ensure that the finished product meets standards.

-

Environmental concerns: With the increasing consciousness of environmental safety, jersey printing strategies are continuously being optimized. the usage of environmentally friendly dyes and methods to lessen environmental pollution is an crucial development path for current jersey printing.

Quality Control and Inspection

-

cloth selection: The initial selection of materials within the early ranges of jersey production is the first step in ensuring quality. This includes analyzing the main fabric, add-ons, and ornamental materials of the jersey to make sure that all substances meet national requirements and consumer necessities.

-

Molding Inspection: After cutting and sewing, jerseys go through an initial molding inspection. This degree specifically checks the scale, style, shoulder width, sleeve duration, and other elements of the jersey to make sure they meet the layout requirements, ensuring comfort and aesthetics whilst worn.

three. Thread give up treatment: Thread ends are commonplace defects in jersey production, and exact thread give up remedy is crucial for great development. take a look at whether or not the thread ends are cozy and if essential flatting has been accomplished to avoid the thread ends from fraying or affecting the arrival.

-

Colorfastness testing: The colorfastness of jerseys at once affects their sturdiness and color retention after washing. Colorfastness checks are performed to make sure that the colors of the jersey do no longer fade for the duration of the washing procedure, preserving the authentic color.

-

useful trying out: useful exams are completed at the breathability, moisture-wicking, and other purposeful elements of the jersey to make certain that it offers an excellent carrying experience at some stage in physical activity.

-

protection check: safety tests are performed at the moving components of the jersey, together with zippers and buttons, to make sure that they may not come off or be damaged during exercising, preventing any sports-associated accidents.

-

Washing check: Simulating actual washing conditions, a washing take a look at is accomplished on the jersey to test its length stability, colour change, and retention of functionality after washing.

-

detail test: special tests are made at the jersey’s details, along with whether or not the sewing is neat, the styles are clean, and the embroidery is comfortable.

nine. Packaging Inspection: in spite of everything inspections are finished, a very last test is performed before packaging to make certain that each jersey meets exceptional requirements and that the packaging baggage are intact.

- factory Inspection: A final inspection is done before the jerseys are shipped to ensure that each one jerseys have surpassed through a rigorous excellent control technique.

through those nice manage and inspection tiers, every jersey is ensured to meet standards, pleasant the customers’ necessities for sports activities device. This not only maintains the emblem photo but additionally respects the customers’ rights.

Customized Jerseys and Market Applications

The system of customizing jerseys is rigorous, aiming to satisfy the diverse desires of various customers. Its programs are large, protecting more than one fields.

detail Customization, showing Individuality. within the customization of jerseys, customers can specify info consisting of hues, patterns, and numbers, making each jersey precise in its personal right. thru meticulous embroidery and printing techniques, elements consisting of crew logos, sponsor logos, and player names are accurately offered, ensuring individualization and professionalism.

Adaptable to numerous sports activities. custom designed jerseys are not restrained to football but are widely used in an expansion of sports such as basketball, volleyball, tennis, and greater. consistent with the characteristics of various sports, customized jerseys are tailor-made in phrases of materials, cuts, and practical features to offer highest quality consolation and capability.

expert group, Strict great control. inside the jersey customization system, a professional layout team is answerable for designing in step with customer requirements, while intently taking part with the production department to make certain the feasibility of design proposals and the exceptional of the production system. every step from raw material procurement to finished product cargo is difficulty to strict quality control.

numerous marketplace programs. custom designed jerseys aren’t simplest used for sports activities occasions however also are widely applied in various fields inclusive of company group building, faculty activities, club memberships, and private collections. In group building, customized jerseys assist enhance team cohesion; in college activities, jerseys end up a platform for college students to show off their individuality; and in membership membership activities, jerseys serve as distinct souvenirs with excessive collectible cost.

Environmental substances, Sustainable development. With the growing consciousness of environmental safety, an increasing number of customized jerseys are using materials. these substances now not handiest offer extraordinary breathability and moisture-wicking homes but additionally meet environmental requirements, reflecting the concept of sustainable development.

custom designed offerings, Attentive and considerate. From the order placement to the transport of the finished product, the customization provider for jerseys will pay attention to every detail. A professional customer service crew presents one-on-one session offerings, answering patron questions to ensure a easy customization manner. furthermore, numerous sizes and patterns are supplied for clients to pick out from, catering to the wishes of various companies of people.

After-sales assure, fear-free service. inside the method of jersey customization, if any troubles stand up, the expert after-income team will reply promptly, imparting answers to the clients. moreover, customized jerseys usually come with warranty services to ensure that clients haven’t any worries throughout use.