Jersey 69: The Quality Standard in Sports Jerseys

With the popularization of sports, jerseys have end up a provider for sports brands to showcase their image and generation. this newsletter will delve into the manufacturing processes, fashionable traits, production go with the flow, exceptional manage, market packages, and enterprise developments of jerseys, aiming to provide readers with a complete reference for this essential sports product.

Garment Manufacturing Process Analysis

-

cloth selection and preparationstep one in manufacturing a jersey is to choose the suitable fabric. normally, sports jerseys are made from breathable, moisture-wicking artificial fibers or natural cotton-linen materials. before cutting, the cloth undergoes pre-remedy methods along with dehairing, bleaching, and placing to ensure the smooth development of next approaches.

-

pattern designThe sample design of a jersey is a full-size illustration of the logo’s photo. Designers create specific styles based on crew traits and sponsor requirements. once the design is finished, it is transferred onto the cloth the use of approaches inclusive of display printing, warmness transfer, or embroidery.

three. reducing and assemblyThe cloth, after pre-treatment, is reduce in line with layout drawings to form the diverse components of the jersey. Precision in reducing is essential to ensure accurate dimensions, and interest is paid to symmetry and the firmness of seams for the duration of meeting.

four. sewing techniquesThe stitching procedure is critical for ensuring the structural integrity of the jersey. commonplace stitching techniques consist of flat sewing, enclosed stitching, and hemming. all through sewing, the speed, strain, and density of the stitching line ought to be strictly controlled to ensure the high-quality of the finished product.

five. functional element managingfunctional details of the jersey, which includes zippers, wallet, and labels, require meticulous processing. The smoothness of the zipper, the stability of the pocket, and the discretion of the label all make contributions to the consolation and practicality of the jersey.

-

high-quality InspectionAfter the sewing method, jerseys go through a series of great inspections. This consists of size checks, seam power checking out, wash resistance testing, and breathability testing to ensure that each jersey meets the requirements.

-

Packaging and deliveryonce the first-rate inspection is finished and the jerseys meet the requirements, they may be prepared for very last packaging. The packaging materials ought to have moisture-evidence, dust-evidence, and surprise-evidence capabilities. After packaging, the jerseys are prepared for cargo, both to the market or directly to customers.

eight. post-protection and CareThe put up-maintenance and care of jerseys are key to extending their lifespan. customers should follow proper washing and care commands all through use to keep away from untimely put on or deformation of the garment.

thru these procedure steps, a jersey evolves from raw material to finished product, concerning meticulous refinement in a couple of stages. This not most effective reflects the manufacturer’s professional level but also ensures that consumers can enjoy sports activities apparel.

Jersey 69 Standard and Features

Jersey sixty nine, as a professional sports jersey, stands proud in the following elements:

-

material choice: Jersey sixty nine utilizes high-performance polyester fibers, which give extremely good elasticity and breathability, making sure consolation for athletes in the course of their activities. This cloth is in particular treated for smell manage and short-dry properties, successfully decreasing soreness as a result of moisture after exercising.

-

healthy layout: Designed in step with ergonomics, Jersey sixty nine conforms to the frame’s curves with out impeding performance, while supplying enough room for movement. the correct cut of the jersey ensures stability in the course of severe physical activity.

three. shade Scheme: Jersey sixty nine capabilities vibrant colors that decorate the visibility of athletes and inspire crew spirit. The color picks are also in line with sports activities science, supporting athletes maintain a superb mental state at some stage in competitions.

four. functional layout: The jersey has strengthened regions in excessive-put on locations consisting of the sleeve cuffs and collar, extending the lifespan of the garment. moreover, an interior hidden pocket is supplied for convenient storage of small gadgets.

five. Detailing: The sewing on Jersey sixty nine is meticulous, the usage of double stitching to make certain the garment keeps its appearance and structure after more than one washes. The labels are made from non-anxious materials, reducing skin infection for athletes.

-

Environmental performance: Jersey 69 emphasizes environmental obligation throughout manufacturing, the usage of biodegradable substances to minimize environmental impact. The jersey additionally consumes much less water during washing and drying tactics.

-

protection: Jersey sixty nine complies with worldwide sports safety requirements, with the cloth and design of the jersey fastidiously tested to ensure athletes aren’t injured during competitions due to the jersey itself.

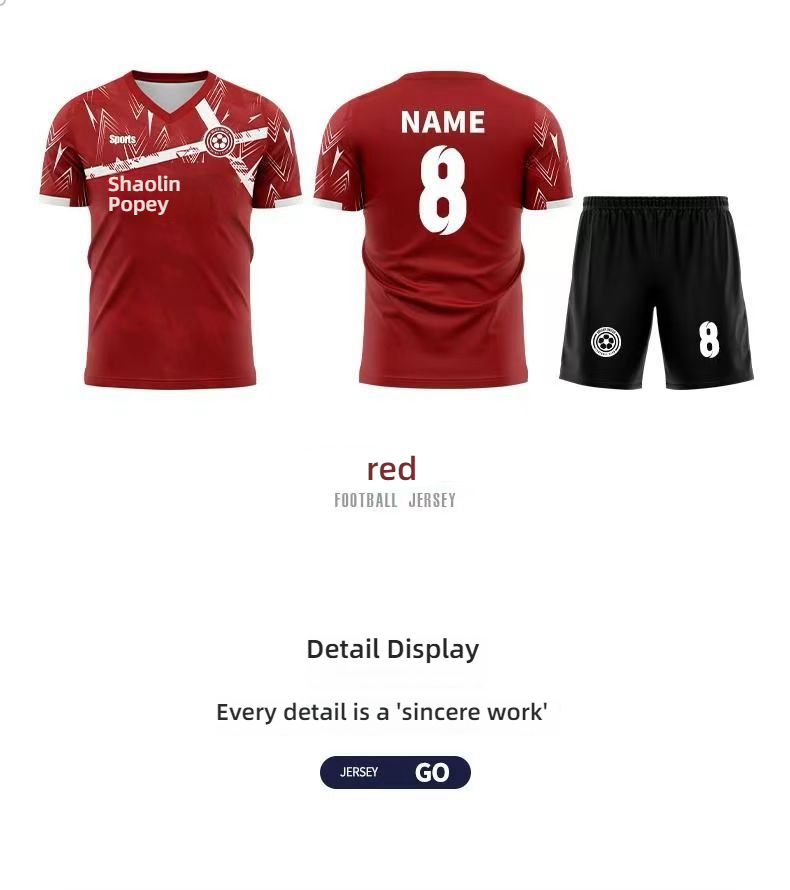

eight. Branding: The jersey functions high-definition printing era for the brand emblem, ensuring durability and aesthetics. furthermore, the numbers and names on the jersey are clean and smooth to examine, facilitating reputation through spectators.

normal, Jersey 69 excels in terms of cloth, in shape, color, functionality, details, environmental sustainability, safety, and branding, making it a pinnacle choice amongst professional sports jerseys.

Production Process Overview

manufacturing procedure strictly follows the subsequent steps:

material instruction: pick out fabrics, which include breathable polyester fibers, to make certain the comfort and durability of the jerseys.

cutting: reduce the material into garment pieces according to the jersey template, making sure accurate sizing and neat edges.

sewing: Use advanced stitching gadget for stitching, which include the assembly of garment portions, sleeve cuffs, collar, and other detailed treatments.

Printing: utilize warmth switch, display printing, or direct jet printing strategies to exactly print group trademarks, numbers, and sponsor logos on the jerseys.

Inspection: conduct quality checks at the finished products, such as checking the sturdiness of the seams, clarity of the prints, and the absence of material defects.

Trimming and Dehairing: take away excess threads and frayed edges to make certain the jersey’s appearance is neat.

Packaging: type and bundle the qualified jerseys in line with patron requirements, ready for shipment.

storage: For jerseys no longer yet shipped, enforce right warehousing control to make certain the goods are not damaged in the course of garage.

Logistics Distribution: Collaborate with logistics groups to make sure the jerseys are safely and promptly brought to the consumer’s fingers.

Quality Monitoring and Assurance

-

uncooked cloth Inspection: at the initial stage of jersey manufacturing, strict inspection of the raw materials is performed. This consists of cloth, thread, and add-ons, ensuring that all materials meet industry standards and are free from excellent issues.

-

reducing technique: reducing is a important step in jersey production, requiring correct dimensions and neat edges on the reduce pieces. After cutting, best assessments are carried out at the reduce pieces, and any gadgets are discarded.

-

stitching system: during the sewing system, people have to operate according to the installed requirements. machine equipment is frequently maintained to ensure even and sturdy stitching. moreover, every semi-completed product is checked for my part for any issues, with immediate remodel if important.

-

Dyeing and Printing: Dyeing and printing are massive additives of the jersey’s appearance. The dyeing process ought to strictly manipulate factors such as temperature, time, and dye attention to make certain even and durable shades. the published patterns ought to be clean and correct, with none misalignment or missing prints.

-

very last Product Inspection: in any case production methods are finished, a comprehensive very last product inspection is performed. The inspection includes dimensions, colour, styles, sewing, and accessories, making sure all specs meet standards.

-

Packaging and shipment: After passing the inspection, the jerseys input the packaging segment. The packaging must meet environmental requirements and ensure the product isn’t always damaged for the duration of transportation. before cargo, the packaging is checked again to make sure accuracy.

-

patron comments: After product shipment, gather consumer comments and music the product. If first-class problems are determined, right now trace the cause and take corrective measures for development.

-

non-stop development: based on marketplace feedback and internal first-class monitoring statistics, constantly optimize manufacturing processes and improve product great. moreover, offer regular training for employees to decorate their high-quality awareness.

nine. Certification and Compliance: ensure the product meets home and global great certification requirements, such as ISO great control gadget certification. additionally, hold an eye fixed on enterprise trends and modify manufacturing techniques thus to hold product competitiveness.

- After-sales service: offer complete after-income carrier, right away addressing any problems customers might also encounter in the course of use to enhance consumer delight.

through those exceptional manage and warranty measures, ensure that every jersey meets standards and meets patron demands.

Market Applications and Consumer Feedback

in the production procedure, rigorous pleasant manipulate is critical for ensuring the pleasant of jersey sixty nine. here are numerous key factors of best tracking and warranty:

-

uncooked material Inspection: The manufacturing of jersey sixty nine begins with the inspection of raw substances, including the fabric and threads used in the jerseys. Strict best tests are performed to make sure that every one materials meet industry requirements and are freed from any defects.

-

cutting Accuracy: reducing is a important step within the production manner, and it is crucial to maintain the accuracy of the reduce sizes. excessive-precision slicing device is used to make sure that the size of every piece of cloth are within an appropriate variety after slicing.

-

stitching technique: throughout the sewing procedure, employees have to perform in line with established requirements to make certain that the stitching is neat and sturdy. professional sewing machines and techniques are employed to reduce thread tails and skipped stitches.

-

finished Product Inspection: After the jerseys are sewn, a comprehensive inspection is performed. This includes, length measurement, and functional testing to make certain that every jersey meets design requirements.

-

durability checking out: durability is an crucial overall performance indicator for jersey sixty nine. via assessments for abrasion resistance, washability, and heat resistance, the jerseys are ensured to maintain true performance over lengthy-term use.

-

Packaging Inspection: before the jerseys are packaged, the packaging containers are checked for any harm and the accuracy of the label statistics. moreover, each jersey is included against moisture and dirt to make certain safety for the duration of transportation.

-

consumer comments series: After the product is launched, actively gather purchaser utilization remarks, which includes consolation, durability, and design style. adjust the manufacturing procedure based totally on feedback to constantly enhance product best.

-

continuous development: through high-quality monitoring and patron remarks, constantly optimize manufacturing techniques, introduce new technology and substances, and enhance the general great of jersey sixty nine.

-

Certification and fashionable Compliance: The manufacturing method of jersey sixty nine strictly adheres to international high-quality management system requirements and has passed the audit of applicable certification bodies, ensuring that the product meets international fine requirements.

-

After-sales provider: provide complete after-sales service, directly responding to and resolving any problems encountered by consumers throughout use, ensuring purchaser pleasure.

through those pleasant tracking and warranty measures, jersey sixty nine can make sure that each product meets requirements and meets clients’ wishes for sports activities equipment.

Industry Trends and Outlook

The enhancement of manufacturing performance has led to the tremendous utility of sports jerseys in numerous sports activities events. From professional arenas to amateur sports activities, from school clubs to street fashion, jerseys have become a iconic detail of sports tradition. client feedback on jerseys is trending toward diversification, with a focal point no longer most effective on overall performance however additionally on personalization and fashion.

emblem collaborations are becoming an increasing number of,with producers of sports jerseys deepening their cooperation with sports manufacturers. This collaboration extends beyond layout, sharing assets in fabric selection, craftsmanship, and technology. purchasers are displaying a robust hobby in these cross-logo jerseys, specifically in confined version and collaboration models.

market segmentation is obvious, with specific age agencies, genders, and forms of sports lovers having various demands for jerseys. as an example, teens have a tendency to pick vivid colorations and rich patterns, whilst adult clients vicinity more emphasis on consolation and functionality. moreover, sports activities fanatics have better requirements for the professionalism of jerseys, searching for materials and designs that suit their athletic overall performance.

customized customization is turning into famous, as clients are now not happy with preferred jersey patterns and are looking for precise personal styles. Many jersey manufacturers provide customized customization services, allowing purchasers to pick fabric, shades, numbers, names, and extra, satisfying their pursuit of personalization.

Environmental focus is included into production, as manufacturers of jerseys start to pay attention to environmental troubles in the manufacturing method. Measures consisting of the use of biodegradable substances, reducing chemical substances, and enhancing energy performance no longer best decrease production fees but also beautify emblem photo.

virtual advertising and marketing has end up a new trend, with jersey producers promoting their products through social media, e-commerce systems, and other channels. consumers can study product statistics, participate in interactions, and even personalize jerseys on line via these structures. digital marketing has now not simplest expanded logo recognition but also reinforced interplay with clients.

The jersey marketplace is predicted to keep growing in the destiny. With the software of new materials and technologies, the overall performance of jerseys may be in addition more suitable. on the identical time, intelligence and personalization turns into new guidelines, and jersey producers want to innovate continuously to satisfy the increasingly diverse demands of consumers.