Modern Sports Jersey Trends: Suitable Fabrics and Eco-Friendly Production for Football/Soccer Jerseys

in the realm of sports competition, the group jersey isn’t always only the uniform of athletes but also a symbol of crew tradition. With the advancement of generation and the diversification of purchaser needs, the production techniques and design principles of jerseys are constantly evolving. this text will explore the modern-day trends in the jersey market and the way the concept of environmental sustainability is being carried out in the production of jerseys.

Overview of Production Process

-

cloth training: the first step in producing group jerseys is to choose the perfect cloth. commonplace fabrics consist of polyester, nylon, and cotton, that are chosen based totally at the kind of recreation and climatic situations. The cloth have to undergo thorough washing, oil elimination, and stain removal to make sure nice.

-

slicing and Seaming: After processing, the fabric moves directly to the reducing stage, in which it’s far reduce in line with the jersey pattern. The cut portions are then sewn collectively to shape the primary components of the jersey, which include the back and front panels, and sleeves.

three. stitching techniques: The pieced material is then sewn on professional stitching machines to make certain strong and neat seams. common sewing techniques consist of flat sewing, enclosed sewing, and hemming.

-

Collar and Cuff treatment: The collar and cuffs are important elements of the jersey and require unique interest. The collar is typically designed as a round neck or V-neck and is completed through sewing or a hooding technique. The cuffs, relying at the fashion, may be made from ribbing or elastic to ensure flexibility and aesthetics.

-

wallet and Label stitching: some jerseys are designed with wallet, which need to be added at some point of the stitching technique. The layout of the pockets must take into account practicality, aesthetics, and sturdiness. further, emblem labels, size labels, and other tags are sewn onto the jersey.

-

Printing and Embroidery: After the primary stitching is entire, the jersey movements on to the printing or embroidery degree. Printing techniques encompass screen printing and pad printing, whilst embroidery is accomplished the use of computerized embroidery machines. This step adds emblem identification and personalised elements to the jersey.

-

satisfactory Inspection: After printing and embroidery, the jersey undergoes a complete fine inspection. This includes checking for secure seams, material for any tears, and shade uniformity to ensure each jersey meets nice standards.

-

Packaging and cargo: The jerseys that skip the excellent inspection are then packaged, generally the use of wrinkle-free and dust-proof packaging materials. once packaged, the jerseys are equipped for shipment, either to retail places or immediately to customers.

The complete jersey production manner is rigorous and meticulous, from cloth selection to completed product shipment. every step displays a pursuit of quality and interest to detail. This not only guarantees the sturdiness and comfort of the jerseys however also meets the demands of sports activities enthusiasts for manufacturers and personalization.

Textile Selection and Processing Technology

the choice of material is a crucial stage in the production of crew jerseys, directly affecting their consolation, durability, and look. In jersey production, there are several commonplace forms of fabric used:

-

Polyester material: Polyester material is widely utilized in jersey manufacturing due to its excessive electricity, elasticity, and resistance to deformation. Its advantages consist of resistance to washing, UV resistance, and suitable breathability. but, it is important to notice that polyester fabric may purpose static power when in contact with the skin, and special processing strategies are required to decrease discomfort.

-

Cotton material: Cotton cloth has extraordinary moisture absorption and sweat-wicking houses, imparting comfort and suitability for put up-workout moisture management. but, cotton is fairly vulnerable in phrases of tensile power and wear resistance, and is vulnerable to pilling. consequently, it is frequently combined with different fabrics like polyester to beautify its performance.

-

Polyester Fiber: Polyester fiber boasts terrific wrinkle resistance and put on resistance, in addition to resistance to pilling, making it appropriate for jersey customers. This type of material is usually used within the production of premium jerseys, especially in designs that aim for a light-weight and technological feel.

-

Spandex cloth: Spandex cloth is famend for its remarkable elasticity and is frequently used inside the neck and sleeve regions of jerseys to provide better freedom of motion. The addition of spandex makes jerseys extra body-conforming and reduces the feeling of restrict at some point of workout.

Key tactics in jersey manufacturing are equally important:

-

slicing: The reducing stage requires unique dimension and cutting of the fabric based at the jersey’s style and design requirements. The accuracy of this step directly impacts the size and appearance of the finished product.

-

Seaming: Seaming is the center system in jersey manufacturing, consisting of numerous methods together with flat sewing, bound sewing, and stitched stitching. seaming requires even stitching and relaxed seams to prevent fraying.

three. warmness switch Printing: warmth transfer printing is a not unusual method for printing styles on jerseys. This technique is suitable for complex styles and presents vibrant hues that are not vulnerable to fading.

- Embroidery: Embroidery is appropriate for exceptional patterns on jerseys, which include team emblems, participant names, and so forth. Embroidery can upload decorative elements to jerseys and meet the personalized needs of players.

five. Coating remedy: to improve the water-resistant overall performance of jerseys, coating remedies can be applied to the cloth floor, growing sturdiness and practicality.

- Environmental safety Processing: With the upward push of environmental attention, more fabrics and strategies are being followed in jersey manufacturing, such as solvent-unfastened coatings and formaldehyde-free dyeing, to limit environmental impact.

In precis, cloth selection and processing era are core components of jersey production, collectively figuring out the performance and first-class of the product. within the pursuit of jerseys, manufacturers want to continuously optimize processes and decorate product competitiveness.

Printing and Embroidery Techniques Analysis

The printing technology performs a essential function inside the production of football jerseys, influencing not simplest their appearance but additionally their sturdiness and the presentation of visible effects. here is an in depth evaluation of the diverse printing techniques used in jersey production:

-

display Printing: display screen printing is one of the maximum common strategies used in jersey printing. It includes making use of the sample to a pleasant mesh screen, after which the usage of a squeegee to pressure the ink via the mesh, growing the layout. This approach is suitable for a ramification of complex patterns and text, and is relatively value-effective.

-

Pad Printing: Pad printing is good for small regions and pleasant styles, mainly for irregular shapes. It uses a soft silicone mildew to transfer ink onto the jersey, making sure clear and unique styles.

-

warmth transfer Printing: warmth transfer printing is a method that transfers a pattern to the jersey floor via excessive warmness. It uses special heat transfer paper, where the sample is first imprinted on the paper, after which transferred to the jersey using a heating tool. This approach is appropriate for diverse jersey materials and consequences in colourful colorations.

four. hot Stamping: hot stamping involves making use of metal foil to the jersey through excessive heat, growing a completely unique metal sleek impact. This approach is frequently used for printing emblem trademarks and sponsor trademarks, presenting high ornamental and identity fee.

five. Laser Engraving: Laser engraving generation uses a excessive-energy laser beam to at once engrave the jersey fabric, suitable for developing clean and sharp patterns. This technique is particularly appropriate for customizing jerseys.

-

Embroidery: although embroidery is usually used for the crew crest, numbers, and other iconic patterns, it’s also an essential printing method. Embroidery ensures the 3-dimensional feel and durability of the pattern, and the colors are bright and do not fade without difficulty.

-

fine control: quality control is vital inside the printing manner to make sure jersey pleasant. earlier than printing, the styles need to be pre-inspected, the ink go with the flow and stress want to be controlled for the duration of printing, and the completed products want to be randomly checked to make sure clear styles, even shades, and no defects including lacking prints or bubbles.

-

Environmental materials: With the increasing focus of environmental safety, increasingly jersey printing is using environmentally friendly inks and biodegradable substances. those inks aren’t only pleasant to the environment but additionally innocent to human fitness, meeting the manufacturing requirements of cutting-edge sports equipment.

via the software of these numerous printing and embroidery strategies, football jerseys can’t most effective exhibit particular logo pix and private styles however additionally make sure their sturdiness and capability, meeting the desires of various occasions and sports activities activities.

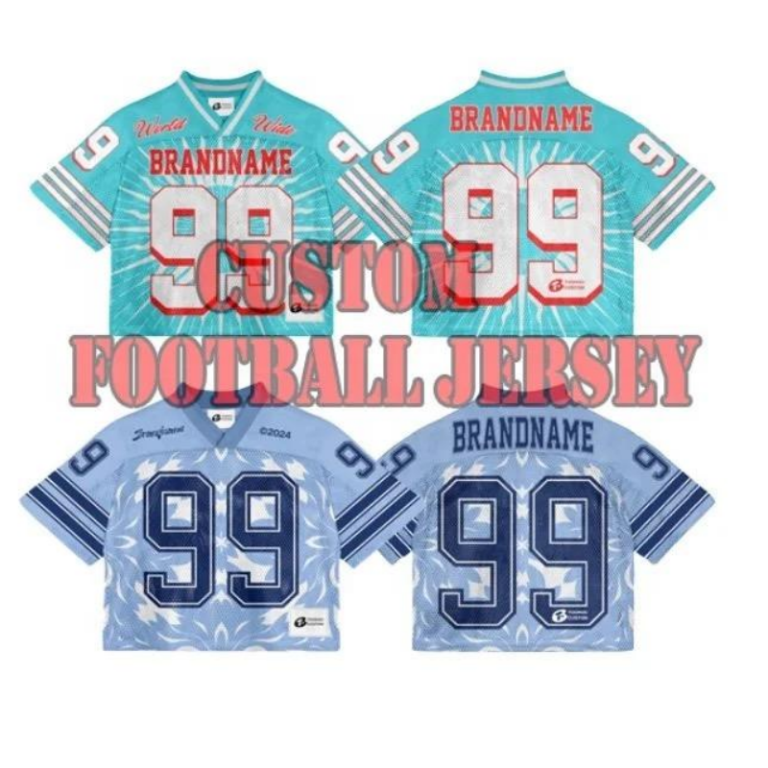

Custom jersey and personalized service

The customization provider for group uniforms plays a extensive function in meeting the numerous desires of teams and gamers. From design to completed product, the following is an in depth breakdown of this procedure:

custom designed sample design gives a extensive range, allowing customers to create specific styles primarily based on group traits, cultural backgrounds, or particular occasions. The design process typically consists of:

- sample introduction: Designers speak with customers to recognize their expectations and fashion choices, growing pattern sketches that meet the desired requirements.

- coloration Schemes: Designers pick suitable shade schemes based on the uniform colorations and accessories, making sure that the pattern coordinates with the general fashion.

- function layout: The unique location of the pattern on the uniform, consisting of the chest, returned, or sleeves, as well as the size and proportions of the pattern, is determined.

the choice of fabric for the uniform immediately influences the comfort and durability of the garment. during customization, clients can select from:

- Polyester fabric: light, breathable, and appropriate for summer season put on.

- Cotton fabric: Absorbent and breathable, appropriate for spring and autumn seasons.

- Polyester Fiber: durable and wrinkle-resistant, appropriate for lengthy-term put on.

the level of workmanship in the sewing technique at once influences the sturdiness and look of the uniform. the subsequent strategies are broadly used in customization:

- Seamless generation: specialised processes reduce seams, enhancing the consolation and freedom of motion of the uniform.

- 3-Dimensional reducing: Designed based totally on ergonomics, making sure the uniform fits the body nicely and affords a better athletic enjoy.

- special sewing strategies: bolstered stitching on regions susceptible to wear and tear to increase the lifestyles of the uniform.

personalized offerings additionally encompass:

- number and name Embroidery: Embroidering participant numbers and names at the uniform to feature private identification.

- special identification: along with crew logos, sponsor marks, and so on., to growth the recognition and emblem exposure of the uniform.

- unique processes: Like hot stamping, laser engraving, etc., to enhance the visual appeal of the uniform.

Uniform cleansing and maintenance are also part of the personalised provider, such as:

- expert cleansing: the use of detergents and methods appropriate for the material of the uniform to make certain the colors remain vibrant and do now not fade easily.

- Dry cleansing offerings: For unique fabric or complexly designed uniforms, dry cleaning offerings are furnished to shield the uniform.

- protection recommendations: presenting preservation hints to help customers expand the lifestyles of the uniform.

through those detailed customization and personalised offerings, the uniform not simplest will become a service for athletes to exhibit their personal style and crew spirit but additionally an critical tool for brand merchandising and marketplace identity.

Quality Control and Testing Standards

in the manufacturing method, satisfactory control is of paramount importance. each stage of the football jersey production ought to go through rigorous fine inspections. right here is a detailed evaluation of this process:

-

raw cloth choice: At the beginning of the soccer jersey manufacturing, the fabric, add-ons, and additives used are strictly decided on to ensure that every one uncooked materials meet global standards. This includes testing the fabric’s put on resistance, breathability, and moisture-wicking residences, in addition to the protection of add-ons along with zippers and buttons.

-

Product Inspection: At every stage of the soccer jersey production, including reducing, stitching, and ironing, dedicated exceptional inspectors supervise and conduct spot checks on-site. final product inspection is a complete great test of the whole jersey in the end methods are finished.

three. useful trying out: As a sports activities clothing, the capability of the football jersey is important. therefore, assessments are carried out on the jersey’s breathability, moisture-wicking, and elasticity to ensure its consolation in the course of workout.

four. Compliance with protection requirements: The safety overall performance of the football jersey cannot be ignored. throughout production, safety performance assessments such as tear resistance, sturdiness, and heat resistance are carried out to ensure that the product does now not purpose harm to the consumer at some point of exercise.

five. Verification of specs and Sizes: the scale of the soccer jersey directly impacts the consolation of carrying it. therefore, every length of the jersey is established in the course of production to ensure it conforms to human ergonomics and fits well.

-

Packaging Inspection: before the football jerseys are packaged, the packaging containers and luggage are checked to make certain that the packaging substances meet environmental requirements, are pollutants-free, and have clear labeling.

-

factory Inspection: earlier than the soccer jerseys are officially shipped, a complete inspection is conducted, inclusive of appearance, capability, and protection performance, to ensure that each jersey meets the manufacturing facility requirements.

eight. consumer comments and continuous development: After the product is offered, client feedback is accumulated, and problems observed are stepped forward to constantly beautify product excellent. at the identical time, issues inside the production manner are analyzed, and manufacturing methods are optimized to lessen the fee of faulty products.

via these tiers, the best of the soccer jerseys is ensured, assembly consumers’ demand for sports activities device. inside the fierce market competition, strict quality manipulate is the key to enhancing logo picture and triumphing patron believe.

Market demand and industry trend analysis

With the vigorous development of the sports enterprise, the market for sports activities clothing has been continuously expanding. As an crucial factor of sports activities goods, the demand for jerseys is showing a fashion of diversification. the following is an analysis of the present day marketplace call for and enterprise tendencies:

purchasers’ pursuit of manufacturers and designs is increasingly intense. consumers are now not satisfied with just the fundamental functional elements of jerseys; they have got a growing demand for logo photo, layout style, and personalization. sports manufacturers are assembly the purchasers’ pursuit of uniqueness and personalization by using launching unique version and confined version merchandise.

The growth in professional sports activities activities is driving the call for for expert-grade jerseys. whether it’s expert leagues or novice competitions, there are stricter necessities for the material, performance, and design of jerseys. The expert-grade jersey market is progressively becoming segmented, with special forms of sports activities, from competitive to amusement, all seeing boom in the jersey marketplace.

With the development of era, the technological content of jerseys is constantly enhancing. excessive-tech features such as smart temperature manage, antibacterial scent prevention, and fast moisture wicking are gradually becoming general features in jerseys. The purchasers’ expectations for the mixing of technology and sports are using the studies and application of related technologies.

Environmental recognition is an increasing number of taking root, and the concept of sustainable development is being contemplated in jersey production. the use of environmentally pleasant substances, decreasing using chemical compounds, and improving recycling rates are a number of the environmental measures that no longer simplest reduce pollution for the duration of the production system however also satisfy customers’ demand for green consumption.

personalised customization services are becoming famous, allowing customers to select special colorings, styles, numbers, and other elements to customise their very own exceptional jerseys. This custom designed provider no longer handiest enhances customers’ feel of participation and pleasure however additionally brings new market possibilities for corporations.

The upward thrust of esports has added a new growth point to the jersey marketplace. The layout of esports jerseys makes a speciality of fashion, emblem picture, and also considers the show effect within the digital environment. The demand in this subject is continuously growing, imparting new development space for the jersey enterprise.

The jersey marketplace is displaying a clear fashion of internationalization. With the boom in international sports events, the impact of global manufacturers is growing more potent. home manufacturers are also actively expanding into the worldwide marketplace, enhancing their competitiveness and logo reputation via participation in worldwide event sponsorships and collaborations.

In precis, the market demand and industry trends imply that the jersey enterprise is heading toward a path of branding, personalization, technologization, environmental friendliness, and internationalization. organizations need to preserve pace with the marketplace and innovate continuously to satisfy the more and more various needs of customers.

Application of environmental protection concepts in jersey production

To limit environmental impact, use sustainable fabrics consisting of natural cotton and recycled polyester;put in force power-saving and emissions-reduction measures at some point of the production procedure to decrease electricity intake and pollutant emissions;utilize non-toxic or low-poisonous dyes and auxiliaries to reduce health hazards to people;put into effect water treatment and waste recycling structures to make certain powerful treatment of wastewater, waste fuel, and strong waste all through production;design jerseys with clean disassembly and recyclability for next recycling;sell virtual design to reduce cloth waste in the sample-making system;behavior environmental training for employees to decorate normal environmental cognizance and decrease pollutants at the source;Collaborate with worldwide environmental certification bodies to make certain that products meet worldwide environmental requirements;Use environmentally friendly substances for product packaging to lessen using non-degradable materials like plastic;through deliver chain management, promote environmentally friendly manufacturing methods amongst upstream suppliers to create a full industrial chain environmental closed loop.