Jersey Knit Fabric: The Ultimate Guide to Clothing, Suits, and Sportswear

Jersey knit, as a popular knitted material, boasts particular properties and luxury, making it broadly used in the discipline of sportswear. this article will delve into the benefits of jersey knit within the manufacturing of crew jerseys, offer corresponding care and protection recommendations, and additionally appearance beforehand at its marketplace developments and capacity programs in the destiny.

Jersey Knit Material Overview

Jersey knit, additionally known as jersey cloth, is a sort of knitted material that is characterised via its specific texture and luxury. crafted from satisfactory fibers that are tightly woven together, jersey knit fabric forms a one-of-a-kind ribbed structure, which provides it with great elasticity and stretch homes.

The surface of jersey knit fabric features a quality ribbed texture, which now not simplest complements the consolation of the cloth but also offers it right breathability. Its gentle contact and thermal homes make jersey knit a preferred choice for garb production.

In phrases of cloth class, jersey knit may be divided into single-sided jersey and double-sided jersey. unmarried-sided jersey has a easy facet and a ribbed facet, while double-sided jersey has each sides with a ribbed texture. This type permits for a numerous range of carrying stories and design aesthetics in jersey knit fabric.

single-sided jersey is commonly used for making underwear, T-shirts, clothes, and different garments. Its easy aspect is appropriate for printing patterns, whilst the ribbed facet offers amazing wearing consolation. Double-sided jersey, due to its versatility in both aspects, is frequently used for sports activities clothing and pajamas, as it has higher elasticity and is right for clothes requiring excessive tiers of comfort.

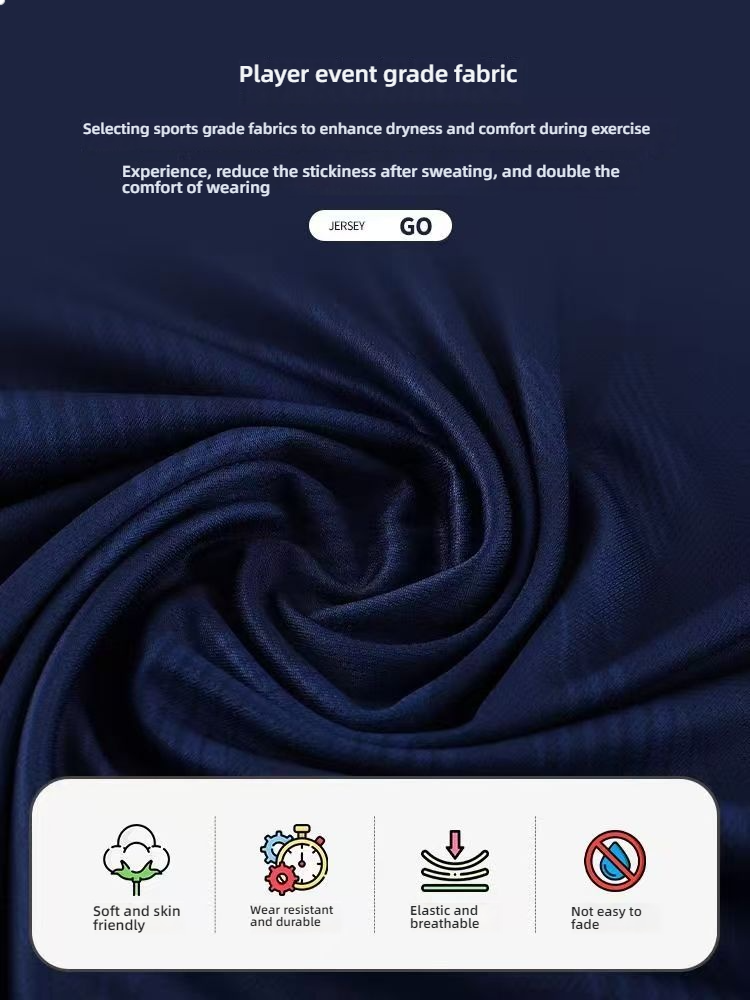

Jersey knit fabric is made from a diffusion of substances, including cotton, polyester, nylon, and spandex. extraordinary substances used in jersey knit fabric vary in terms of hand feel, breathability, and thermal properties. for instance, cotton jersey knit is soft and pores and skin-friendly, suitable for wearing at some stage in spring and summer time; polyester jersey knit is long lasting and clean to scrub, perfect for sports clothing; nylon jersey knit is warmth-resistant, appropriate for winter garb; and spandex jersey knit has splendid elasticity, typically utilized in shaping garments.

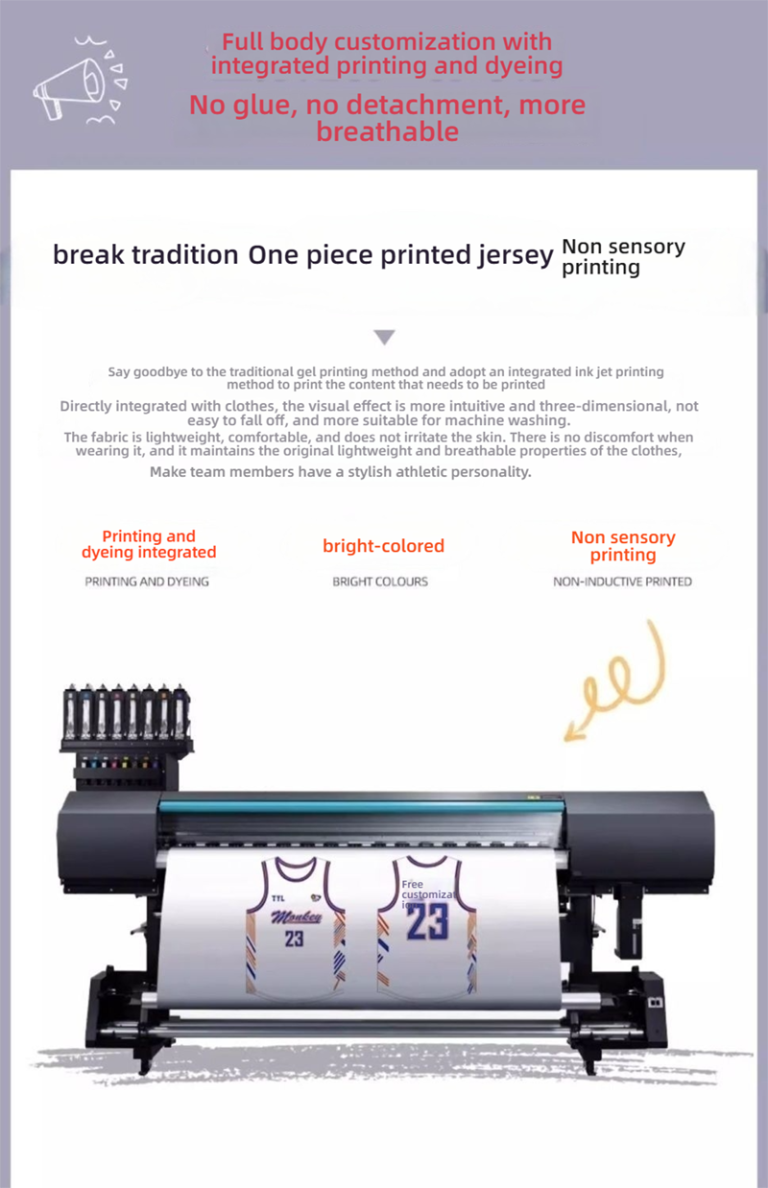

In terms of dyeing and processing, jersey knit material is easy to dye and gives vibrant colorations and rich patterns, and it is also resistant to fading. moreover, extraordinary completing strategies consisting of softening, shrink resistance, and water-repellent treatments can in addition improve the overall performance of jersey knit fabric.

due to its precise residences and numerous packages, jersey knit material holds an vital position inside the style industry and the sports apparel market. From everyday put on to expert sports device, the flexibility and comfort of jersey knit make it a favorite preference among designers. With the increasing demand for first-rate and comfort from consumers, the market call for for jersey knit fabric is on the rise, and it’s far anticipated to play a unique role in extra fields within the future.

Jersey knit characteristics and applications

Jersey knit, additionally known as jersey material or sports wear knit, is a common fabric this is extensively appreciated for its unique elasticity and comfort. under is an in depth description of the traits and applications of jersey knit material:

it is woven from unmarried or a couple of strands of yarn through knitting strategies, which leads to a material surface with rich textures and elasticity. The characteristics of jersey knit are as follows:

- right Elasticity: Jersey knit fabric has high-quality elasticity, permitting it to stretch and retract, imparting a comfy healthy and a nice carrying revel in.

- Breathability: due to its knitted shape, jersey knit cloth has right breathability, which aids within the evaporation of sweat, preserving the skin dry.

- gentle and cozy: The cloth is tender and feels suitable to touch, making it appropriate for use as both and outerwear.

- brilliant colorings: Jersey knit may be dyed in a huge variety of colours, with vibrant and sturdy shades.

Jersey knit has a huge variety of packages, specifically along with:

- clothing industry: Jersey knit is typically used to make sportswear, inclusive of recreation T-shirts, game shirts, and sport pants, due to its elasticity and luxury, making it a really perfect desire for sports activities attire.

- lingerie enterprise: lingerie items like underclothes, nightgowns, and pajamas benefit from the softness and moisture-wicking houses of jersey knit, making it a fabric of preference for these products.

- little one products: The smooth and skin-pleasant nature of jersey knit material makes it suitable for making baby garb and diapers.

- home Decor: Jersey knit is also used for home decor items inclusive of curtains, bedding, and towels, thanks to its comfort and ease of cleansing, making it a famous desire for household products.

in the style industry, jersey knit cloth is used for its unique texture and layout versatility. Designers take gain of its malleability to create a diffusion of styles and silhouettes, from relaxed informal put on to tight-fitting shaping clothes. additionally, jersey knit holds an area in practical clothing, along with solar protection clothing and windbreakers, with its layered structures enhancing warm temperature and waterproofing.

With technological advancements, jersey knit cloth is likewise being constantly improved, with using substances and new fibers to enhance its sustainability and performance. those enhancements hold jersey knit fabric competitive within the market and promise to extend into greater application areas within the future.

Jersey Knit Production Process Explanation

The production system of jersey knit involves multiple steps, special underneath:

-

Fiber selection and coaching: the first step in generating jersey knit is to pick the proper fibers. common fibers used include polyester, nylon, cotton, etc. The fibers are cleaned, decontaminated, and stretched to make sure nice.

-

Spinning: The wiped clean fibers are sent to a spinning machine wherein they are twisted to shape yarn. The yarn have to maintain a sure tension in the course of the spinning manner to make sure the excellent of the very last knitted cloth.

-

Knitting: The yarn is then knitted on a knitting device to shape the simple shape of jersey knit. The knitting manner includes each warp and weft, with jersey knit usually the usage of weft knitting, where the weft yarn forms loops between the warp yarns.

-

Pre-shrinking remedy: The knitted jersey knit material is then subjected to pre-shrinking treatment to decrease shrinkage in the finished product. This treatment is normally performed beneath high temperature and stress, together with the use of steam or warm water.

-

Dyeing: The pre-shriveled jersey knit cloth enters the dyeing method. special dyeing strategies may be selected primarily based on purchaser requirements, which includes direct dyeing, reactive dyeing, or disperse dyeing.

-

finishing: After dyeing, the jersey knit cloth undergoes completing approaches, such as putting, softening, and anti-wrinkle remedies. those steps improve the consolation and durability of the product.

-

Inspection: first-rate inspections are completed at every degree of production to make sure the jersey knit cloth meets standards. Inspections consist of fiber first-class, knitting nice, and dyeing uniformity, amongst others.

-

slicing: certified jersey knit material is then reduce to the required size and shape. Precision is maintained in the course of the reducing manner to accommodate subsequent stitching techniques.

-

stitching: The cut jersey knit cloth actions directly to the sewing level, which incorporates sewing, hemming, and meeting. those approaches make sure the aesthetic and durable nature of the finished product.

-

Packing: The sewn jersey knit finished merchandise are then packed for cargo. The packing manner desires to defend the goods to prevent harm all through transportation.

-

Logistics and Distribution: The packed jersey knit merchandise are shipped to the patron via logistics channels. The logistics manner need to ensure the secure and well timed transport of the products.

The production process of jersey knit entails severa ranges, every of which has a extensive impact at the final exceptional of the product. From fiber choice to completed product packaging, every step ought to be strictly controlled to make sure the first-class and overall performance of jersey knit.

Jersey knit advantages in jersey making

Jersey knit cloth boasts top notch elasticity and stretchability, which brings about several vast blessings within the manufacturing of sports wear.

wonderful Elasticity: The tightly woven yarns in jersey knit form a rich texture shape, endowing the cloth with notable elasticity. inside the making of sports wear, this elasticity permits the garments to comply to the frame’s contours, offering tremendous comfort in the course of movement and reducing the feeling of.

suitable Breathability: The shape of jersey knit permits air to circulate, with the fabric surface having microscopic pores that assist evaporate sweat, maintaining the wearer dry and comfortable.

tender and secure: the texture of jersey knit is tender and sensitive, with minimum friction towards the skin, lowering inflammation and enhancing the sporting consolation.

Uniform Dyeing: Jersey knit material can uniformly soak up dye during the dyeing technique, isn’t susceptible to fading, and guarantees the vibrant and durable shades of the sports wear.

clean to clean: Jersey knit material is immune to washing, does no longer effortlessly deform, and is convenient to clean and maintain, extending the lifespan of the sports clothing.

Adaptability: Jersey knit can adjust the yarn density and weaving system according to design necessities, making it appropriate for the manufacturing of different styles and purposeful sports wear.

Anti-wrinkle performance: Jersey knit cloth has a positive diploma of anti-wrinkle houses, so even though creases appear for the duration of put on, they can easily be stretched lower back to a flat kingdom, lowering the trouble of upkeep.

Aesthetics: The surface texture of jersey knit cloth is wealthy, taking into consideration the introduction of numerous styles and patterns to satisfy the design needs of sportswear for exclusive sports.

sturdiness: Jersey knit material is robust and sturdy, capable of resist positive mechanical wear, and is not effortlessly damaged, suitable for long-term put on.

Antibacterial residences: Jersey knit material has positive antibacterial houses, which help lessen the increase of bacteria and the production of odors, preserving the hygiene of the sportswear.

In precis, because of its severa benefits, jersey knit is increasingly used in the production of sports clothing and has become the preferred material desire for plenty sports brands.

Care and Maintenance Guide for Jersey Knit

Jersey Knit blouse Care and protection manual:

-

Water Temperature manage: when washing jersey knit shirts, keep away from the use of excessive temperatures. it’s far encouraged to use cold water or lukewarm water to prevent the fibers from deforming or being broken by means of immoderate heat.

-

Hand Washing vs. gadget Washing: for thin jersey knit shirts, hand washing is usually recommended to minimize damage as a result of mechanical force. If gadget washing is vital, choose a sensitive cycle and ensure the shirts are located in a laundry bag to prevent tangling and put on.

three. Detergent choice: keep away from the usage of detergents containing bleach or sturdy degreasers, as those components may also damage the jersey knit fibers. choose a slight laundry detergent or a specialized sports apparel detergent.

four. Soaking Time: Do not soak jersey knit shirts for too lengthy; generally, no more than 30 minutes to save you dye switch or immoderate fiber rest.

five. Drying method: whilst drying jersey knit shirts, keep away from direct daylight, as UV rays can accelerate fading. alternatively, lay them flat or dangle in a cool, nicely-ventilated area to dry.

-

stopping Shaping: keep away from striking the shirts on sharp corners or tough gadgets to prevent deformation. If putting is important, use a proper hanger and ensure the width matches the blouse’s shoulder width.

-

Ironing pointers: If ironing is required, use a low-temperature steam iron and spray a small quantity of water at the blouse before ironing to help repair its form. begin from the interior of the shirt and avoid direct contact with the heat source to save you floor damage.

-

garage surroundings: shop jersey knit shirts in a dry environment to save you mildew because of moisture. additionally, hold the clothes far from strong-smelling objects inclusive of perfume or cosmetics to avoid scent absorption.

-

regular cleansing: frequently easy jersey knit shirts to hold their cleanliness and increase their lifespan. Plan the cleansing cycle based on the frequency of use and real situations.

-

expert upkeep: For specifically precious jersey knit shirts, consider taking them to a expert laundry provider for proper care and preservation to make certain the shirts get hold of good enough treatment and care.

Jersey Knit Market Trends and Future Development

Jersey knit, as a famous knitted material, shows several traits in its market trends and future improvement:

-

increasing popularity of PersonalizationWith the developing demand for customization among clients, jersey knit’s software within the garb enterprise is increasingly more focusing on personalised customization. clients can choose from distinctive colorings, styles, and patterns in step with their possibilities, making jerseys made from jersey knit greater identifiable and unique.

-

growing Environmental recognitiondriven by using global environmental concerns, the production technique of jersey knit is becoming extra environmentally friendly. Many manufacturers are adopting sustainable substances along with recycled polyester and organic cotton to lessen environmental impact.

-

Fusion with purposeful fabricJersey knit fabric is regularly being mixed with practical fabric, incorporating special houses like antibacterial, moisture-wicking, and sun safety to satisfy the dual desires of consolation and performance for sports fans.

four. go-industry Collaboration and InnovationThe software of jersey knit cloth is increasing, with collaborations throughout numerous industries inclusive of fashion, sports, and generation. This collaboration not only drives innovation in jersey knit products however also brings new boom points to the marketplace.

-

E-trade platforms Boosting incomeWith the speedy improvement of e-trade platforms, the income channels for jersey knit jerseys have turn out to be greater diverse. on-line income have come to be an vital technique for logo promoting and income, permitting consumers to purchase their favored merchandise extra with ease.

-

Intensified marketplace oppositionThe jersey knit marketplace is becoming increasingly competitive, and brands need to constantly improve product first-class, layout stages, and logo have an impact on. at the same time, technological innovation and value manipulate have grow to be key to the survival of corporations.

-

future development tendencieswithin the future, jersey knit material is anticipated to gain in addition development inside the following components:

- Intelligence: via integrating net of things generation, jersey knit jerseys could have smart tracking and health control functions.

- high performance: continuously optimizing material performance to beautify consolation and protective traits for sports activities sports.

- inexperienced and Environmental: continuously developing fabric to reduce environmental effect at some point of manufacturing.

- Cultural Integration: Combining distinct nearby cultures to create jersey knit jersey merchandise with specific characteristics.