Jersey Printing Machine Guide: Enhancing Sports Apparel Customization with X Jersey Fabric

The sports activities clothing marketplace is more and more, with customized customization becoming a trend. The jersey printing machine, as a key system to fulfill this demand, has a wide range of packages. this article will delve into the utility of jersey printing machines in the sports garb enterprise, in addition to how to properly maintain and take care of these gadgets to make certain their strong operation.

Overview of Jersey Printing Machines

The jersey printing machine, as an crucial gadget inside the production of sports activities garb, has emerge as the primary preference for lots sports activities manufacturers and customized shops because of its high performance and specific printing results. these machines cannot only meet the big-scale customization desires of expert sports teams however additionally satisfy the personalised printing necessities of people or small-scale stores.

The operating principle of jersey printing machines is primarily based on either switch or direct inkjet generation. switch printing machines use excessive temperatures to transfer pre-designed styles onto jerseys, even as inkjet printing machines without delay spray ink onto the jersey material to form patterns. both methods have their very own blessings; transfer printing gives vivid colors and wear resistance, at the same time as inkjet printing is more bendy and flexible.

The marketplace offers a extensive kind of jersey printing machines, ranging from easy guide operation to automated smart machines, with functionalities starting from unmarried-color to full-colour, assembly the wishes of various levels of customers. For professional sports activities teams, purchasing massive, excessive-precision switch printing machines may be vital; for small-scale stores, but, they may pick extra person-pleasant and moderately priced inkjet printing machines.

when deciding on a jersey printing gadget, users want to recall a couple of elements. first of all, pick out the suitable version primarily based on the dimensions of production and finances. Secondly, recall the printing speed and efficiency, as fast manufacturing potential is crucial throughout peak intervals or massive orders. moreover, the complexity of the patterns and the variety of colors will even have an effect on the choice of printing gadget, with complete-colour machines having a bonus in coping with complex patterns.

Jersey printing machines have a wide range of applications inside the sports apparel enterprise. whether or not it’s professional league groups, custom designed jerseys for amateur sports groups, or personalised sports activities T-shirts, jersey printing machines play a essential role. They not handiest ensure the readability and sturdiness of the patterns however also can speedy alter to meet various design styles.

throughout use, the upkeep and care of jersey printing machines are equally important. ordinary cleaning can prevent ink clogs within the print heads, making sure printing first-rate. additionally, proper operation and renovation can enlarge the lifespan of the system, reduce failure quotes, and decrease long-time period operating costs.

As an critical gadget in the production of sports activities garb, jersey printing machines carry remarkable convenience to the sports activities apparel industry with their numerous features and efficient printing results. whether for professional groups or man or woman customers, making an affordable choice and keeping the jersey printing gadget can enhance product quality and production performance.

Types of jersey printing machines explained

there are various sorts of jersey printing machines, which may be extensively labeled primarily based on their working principles and application scopes as follows:

-

display Printing Machines: display printing machines have been the number one system for jersey printing inside the early days, preferred for their low cost and correct printing best. They transfer patterns onto jerseys via monitors, appropriate for jerseys of diverse materials.

-

Pad Printing Machines: Pad printing machines are appropriate for complex patterns and nice traces, moving patterns onto jerseys to achieve high-precision printing results. they’re in particular appropriate for the special necessities of sports manufacturers.

three. Thermal switch Printing Machines: these machines transfer shades from a patterned transfer paper onto jerseys via heating, resulting in colourful shades and durability, making them appropriate for mass production of jerseys.

- virtual Printing Machines: virtual printing machines use inkjet technology to print styles without delay onto jerseys, with out the need for plate-making. they’re perfect for small batch and personalized customization of jerseys, with high shade fidelity and speedy printing speeds.

five. warmth switch Printing Machines: heat transfer printing machines observe styles onto jerseys thru excessive temperatures, suitable for situations requiring put on and water resistance, consisting of on-area jerseys.

-

Laser Engraving Machines: Laser engraving machines use laser beams to engrave patterns onto jerseys, appropriate for personalized jerseys such as athletes’ names and numbers, presenting a high artistic and technological feel.

-

aggregate Pad Printing and digital Printing Machines: those machines combine the benefits of pad printing and virtual printing, allowing complex pattern printing at the same time as meeting the desires of small batch manufacturing.

-

computerized non-stop Printing Machines: automated non-stop printing machines are appropriate for big-scale production lines, able to constantly printing a couple of jerseys, for this reason enhancing manufacturing performance.

each form of jersey printing system has its unique capabilities and application situations, and selecting the proper system is crucial for making sure the best of jersey printing. as an example, expert sports activities teams that pursue excessive first-rate and durability may additionally choose screen printing machines or warmth switch printing machines; whilst sports manufacturers that are trying to find brief reaction and personalized customization may locate virtual printing machines more suitable.

Principle of Operation for a Jersey Printing Machine

-

sample coaching: earlier than the jersey printing begins, the first step is to put together the pattern. this is usually finished using computer design software program, and the design is then output in a format appropriate for printing.

-

Ink blending: The ink used in the printing system needs to be mixed in keeping with the fabric and shade necessities. Ink mixing includes figuring out parameters together with shade, viscosity, and drying pace to make certain the printing effects meet the required requirements.

-

cleansing the Printing Head: earlier than starting the printing process, the printing head ought to be cleaned to eliminate any residual antique ink or impurities. This ensures that the brand new sample is clear and freed from.

-

Printing strain manage: for the duration of printing, the printing head applies a sure quantity of stress to the jersey fabric to make sure that the ink is flippantly transferred. pressure manipulate is critical for the pleasant and readability of the pattern.

five. Ink switch: while the printing head actions to the corresponding position of the sample, ink is ejected and transferred to the jersey via first-rate displays. This system requires particular manipulate of ink drift and pace.

-

warm Air Drying: depending on the jersey fabric, some inks may additionally require hot air drying to boost up the drying technique. hot air drying can speedy evaporate the moisture within the ink, fixing the sample onto the jersey.

-

Curing remedy: For certain types of ink, which includes oil-based totally ink, curing remedy may be important to make certain the sturdiness of the pattern. Curing treatment usually involves excessive-temperature baking to bond the ink firmly with the jersey cloth.

eight. Calibration and Adjustment: for the duration of the printing system, it is necessary to continuously calibrate the diverse parameters of the printing gadget, along with strain, speed, and function, to ensure regular printing effects on every jersey.

-

Repeating Printing: After finishing the printing of one pattern, the printing system can be adjusted to the position of the following sample and preserve with the printing of the following pattern. This process may be repeated until all styles are revealed.

-

satisfactory Inspection: After printing is whole, the completed product needs to be inspected to ensure that the readability of the pattern, colour accuracy, and jersey first-class all meet the specified standards.

The running precept of a jersey printing gadget is a complicated process that requires precise technical operation and system protection to make sure the exceptional and aesthetics of the final product.

Factors to consider when choosing a jersey printing machine

while selecting a jersey printing gadget, it’s miles necessary to keep in mind the following aspects comprehensively:

-

Printing era: Jersey printing machines can utilize numerous strategies, which includes display printing, pad printing, and virtual printing. display screen printing is suitable for huge-scale production, pad printing is right for high-quality styles, and virtual printing offers greater flexibility. pick out the perfect printing generation based on the complexity of the jersey styles and manufacturing quantity requirements.

-

Printing pace: distinct fashions of jersey printing machines range substantially in terms of printing speed. excessive-pace machines are suitable for huge orders, even as medium to low-speed models are better for small-batch customization. select the best printing speed in line with real production wishes.

-

Printing Precision: The precision of jersey printing at once impacts the very last product first-class. printing machines make sure clear patterns, colourful colours, and neat edges. whilst shopping, pay attention to the gadget’s resolution and printing precision parameters.

four. fabric Compatibility: Jerseys are made from diverse substances, along with cotton, polyester, and blends. when choosing a jersey printing machine, take into account whether or not it’s far appropriate for the selected cloth. some printing machines won’t be nicely-proper for positive materials, leading to negative printing results.

five. Ease of Operation: consumer-pleasant jersey printing machines can reduce labor costs and improve manufacturing efficiency. whilst deciding on, be aware of whether or not the device’s operation interface and manage device are smooth to use.

-

protection and carrier: Jersey printing machines require normal renovation and service to make sure solid operation. when buying, apprehend the gadget’s protection cycle, components supply, and after-income service.

-

brand and fee: there are numerous brands of jersey printing machines available on the market with varying costs. while making a buy, don’t forget your finances and logo popularity to make a choice. manufacturers generally offer greater comprehensive technical assist and after-income provider.

-

extra features: some jersey printing machines have extra capabilities including warm stamping and thermal switch. based on actual desires, choose a system with additional capabilities to meet more various production requirements.

-

safety: Printing machines may also pose protection hazards at some stage in use, consisting of excessive temperatures and excessive pressures. whilst purchasing, take note of the system’s safety safety measures to make sure manufacturing safety.

-

Environmental performance: With the growing consciousness of environmental protection, the environmental performance of printing machines has additionally emerge as an essential element in choice. choose environmentally pleasant printing machines to help reduce pollutants emissions for the duration of production.

considering these factors will help in choosing the right jersey printing device, in an effort to make contributions to enhancing production performance, ensuring product first-class, and decreasing production charges.

Apparel Printing Machines in the Application of the Sports Apparel Industry

-

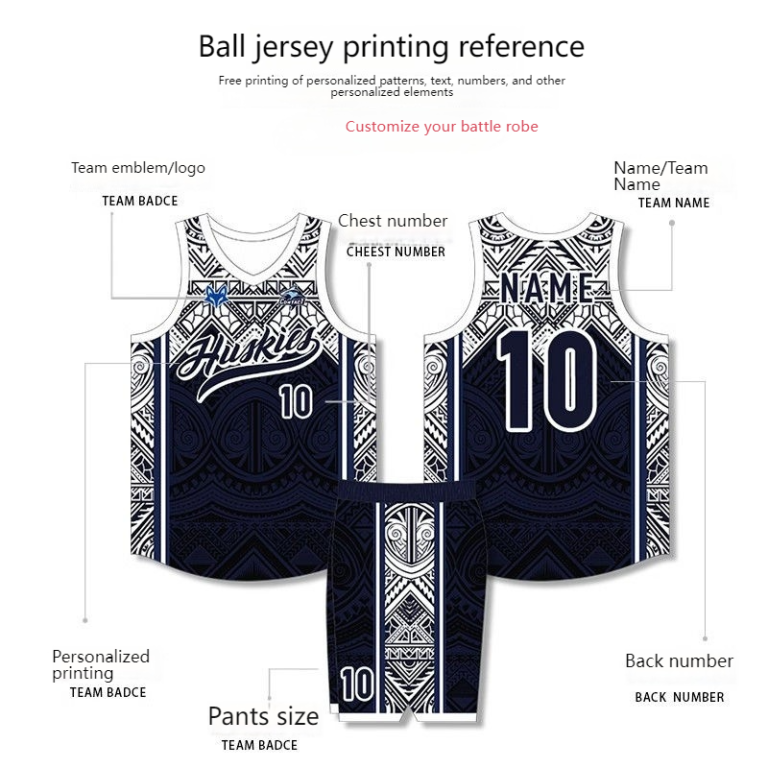

personalised Customization: sports activities garb manufacturers can use jersey printing machines to customize personalised jerseys for customers. whether or not it’s membership logos, player names and numbers, or special version jerseys, the printing machines can attain unique replication of patterns and textual content, satisfying customers’ pursuit of specialty.

-

brand advertising: sports activities brands show their trademarks, slogans, or sponsor facts on jerseys the usage of jersey printing machines, which not simplest complements emblem visibility but also serves as a transferring billboard all through fits, efficiently lifting logo image and marketplace have an impact on.

three. Promotional sports: at some point of sports occasions, brand activities, or holidays, sports activities clothing manufacturers frequently release restricted edition jerseys, which can be commonly produced by jersey printing machines. those jerseys, with particular patterns or designs, appeal to consumers and force income.

-

Sponsorship Collaboration: professional sports activities golf equipment associate with sponsors to showcase sponsor brands on jerseys using jersey printing machines. This collaboration version now not most effective brings economic blessings to the golf equipment but additionally raises the sponsor’s brand reputation within the public eye.

-

crew Uniform Customization: one-of-a-kind sports activities have various necessities for group uniforms, and jersey printing machines can accommodate numerous materials and hues, assembly the expert desires of various sports. as an instance, basketball, soccer, tennis, and different sports require team uniforms with specific functionalities and design styles.

-

competitive occasions: In diverse sports activities competitions, jersey printing machines are key device for generating suit uniforms. whether it’s national or worldwide occasions, jerseys want to be revealed precisely to make sure the uniformity and standardization of the fit uniforms.

-

participant interaction: Athletes converting jerseys throughout matches isn’t always handiest part of the competition but also a shape of interaction among gamers. Jersey printing machines can fast produce jerseys with precise patterns or meaningful memorabilia, presenting more possibilities for participant interaction.

-

competition records: certain unique fits, consisting of championship games or memorial games, require the manufacturing of restricted edition jerseys as souvenirs. Jersey printing machines can quickly meet those special custom demands, permitting creditors to very own particular keepsakes.

nine. marketplace enlargement: as the sports clothing market continues to segment, jersey printing machines help manufacturers expand into new market areas, consisting of kid’s sports apparel and unfashionable sports activities garb, meeting the desires of different purchaser corporations.

- art Integration: cutting-edge sports garb layout an increasing number of emphasizes the mixture of artistry and capability. while keeping the practical functions of jerseys, jersey printing machines also offer designers with wealthy creative area, turning sports apparel right into a fusion of style and artwork.

Guide for Maintenance and Care of Jersey Printing Machines

deciding on the right jersey printing system is crucial, but renovation and care are similarly essential. right here are some key factors for the maintenance and care of jersey printing machines:

-

ordinary cleansing: at some point of operation, the printer’s nozzles and ink cartridges are prone to build up dust and grime. regularly wipe these areas with a clean cloth to ensure the device’s surface remains clean and to keep away from impurities affecting the print high-quality.

-

Ink control: using ink can lessen the threat of nozzle clogs. regularly test the ink first-class and keep away from using expired or low-excellent inks. while storing ink, make certain it’s far sealed to save you evaporation and oxidation.

three. Nozzle preservation: The nozzle is a middle component of the jersey printing system, responsible for exactly making use of ink to the jersey. regularly smooth the nozzle the use of professional cleaning answers to clear clogs and make sure even ink application.

- Temperature manage: The temperature of the ink and jersey at some stage in printing has a vast effect at the print fine. maintain the suitable temperature to keep away from excessive or low temperatures that may affect the drying velocity of the ink and the pliability of the jersey.

five. electricity balance: using a strong energy deliver is essential for jersey printing machines. Voltage fluctuations can cause system malfunctions, so it’s miles recommended to apply a voltage stabilizer to make certain solid voltage.

-

ordinary Calibration: through the years, printing machines may also experience misalignment or erroneous positioning. frequently calibrate the gadget to make sure particular printing positions.

-

investigate Mechanical parts: regularly take a look at the device’s mechanical components, inclusive of tracks, gears, and bearings, to make certain they may be operating usually. replace them directly if there’s wear or damage.

eight. garage environment: whilst not in use, store the jersey printing gadget in a dry, well-ventilated surroundings to keep away from damage from moisture and high temperatures.

nine. Operation manual: make yourself familiar with the operation manual of the printer and observe the manufacturer’s tips to avoid device damage due to wrong operation.

- professional renovation: For complex jersey printing machines, it is recommended to have them checked and maintained with the aid of expert technicians on a ordinary foundation to make certain they are in choicest working circumstance.

by way of following those maintenance and care measures, you can correctly increase the lifespan of the jersey printing machine, make certain print pleasant, and enhance manufacturing performance.