72 Quality Standards for Football Jersey Suitability and Design

With the fast development of the sports industry, jerseys, as an critical element of sports activities apparel, are experiencing a fast-paced transformation of their design, manufacturing, and income markets. this text will discover the key elements of the jersey industry, along with material selection, manufacturing techniques, custom offerings, sizing measurements, sturdiness and functionality considerations, brand collaborations, nice manage, and after-sales provider, and also will are expecting destiny enterprise developments.

within the global of sports activities competition, the jersey isn’t always simplest the athletes’ armor but also a image of emblem photo and group spirit. the producing method of jerseys is tricky and delicate, and the subsequent is a detailed analysis of its production.

the manufacturing of jerseys begins with the choice of the material. fabric ought to have desirable breathability, moisture-wicking and perspiration capabilities, and abrasion resistance. not unusual fabric for jerseys available on the market encompass polyester, nylon, and polyester fiber, among others. deciding on the suitable material in line with extraordinary sports activities requirements is the important thing to making sure the overall performance of the jerseys.

The slicing segment is the foundation of jersey manufacturing. through specific dimension and pc-aided layout (CAD) software, designers can ensure that each element’s dimensions are accurate. The cutting process combines device cutting with guide slicing to make sure the neatness and accuracy of the cut pieces.

sewing is the core step in jersey production. modern jersey sewing uses computer-controlled multi-needle stitching machines that can achieve excessive-speed and particular stitching. special attention need to be paid to the firmness and aesthetics of the seams, as well as the dealing with of info including sleeve openings and collars.

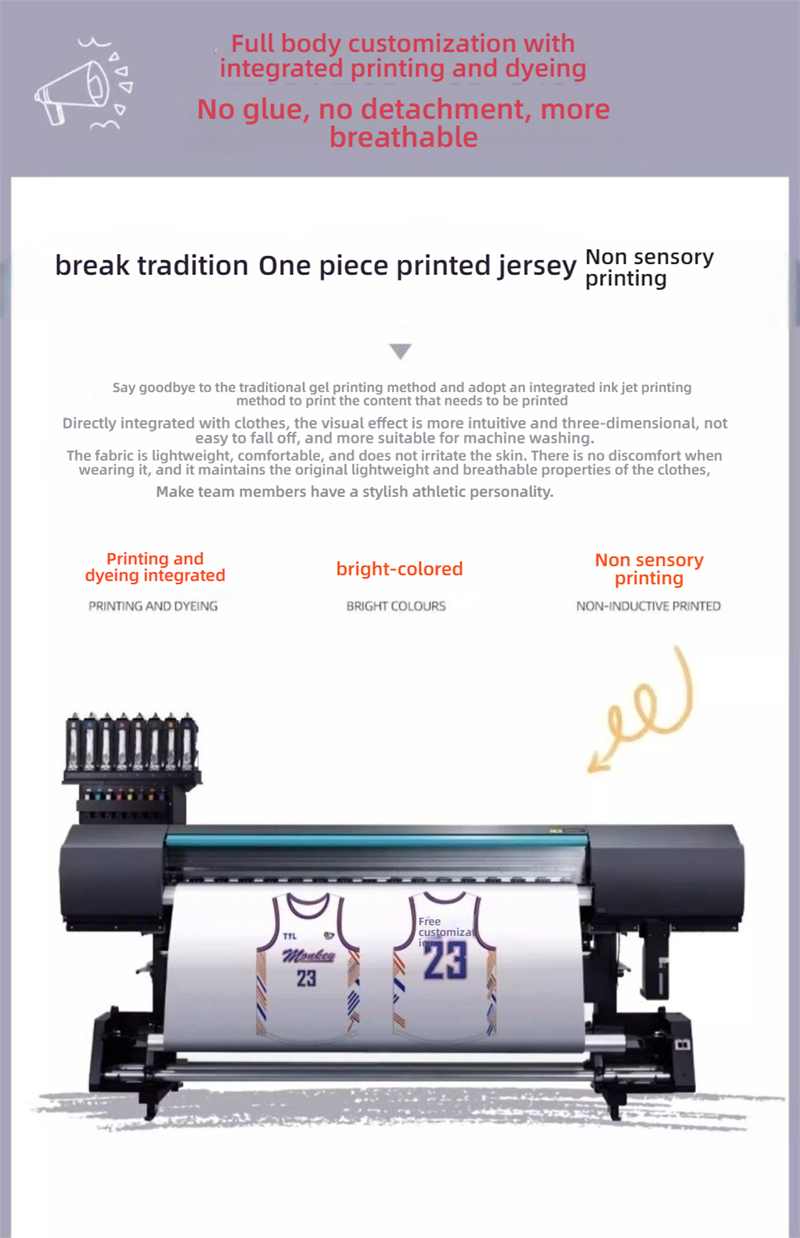

The application of digital printing technology makes jersey sample printing more accurate and diverse. traditional screen printing is fee-effective, however it has obstacles in pattern complexity. digital printing can print any sample, with vibrant hues, clean layers, and is not liable to fading.

The layout of jersey fits takes into account ergonomics ideas to make certain consolation and flexibility during exercising. The in shape design must adapt to athletes of different frame sorts as well as meet the requirements of movements for the duration of exercise.

To beautify the sturdiness of jerseys, producers upload reinforcement to crucial areas such as shoulders and elbows, which are frequently rubbed. moreover, the zippers, buttons, and different add-ons are selected from merchandise to make certain overall sturdiness.

In phrases of manufacturing control, jersey production factories normally undertake strict quality control structures. From raw fabric procurement to finished product transport, every level has distinct inspection requirements. After-sales service is likewise a key to making sure patron pleasure, together with cleansing, protection, and repair of jerseys.

as the sports activities industry continues to expand, jersey production techniques also are progressing. in the future, shrewd and environmentally pleasant production strategies turns into tendencies. for instance, the use of three-D printing era to supply customized jerseys or adopting recyclable substances to lessen environmental impact.

In precis, the manufacturing system of jerseys includes a couple of ranges inclusive of fabric choice, reducing, stitching, printing, fit design, durability remedy, and production control. every stage displays the manufacturer’s pursuit of best and appreciate for the needs of athletes.

Material Selection and Performance Requirements

the selection of material material for football jerseys is vital for the overall performance of the very last product. below is a detailed description of the fabric choice and performance requirements:

-

material cloth: The fabric for football jerseys is usually crafted from artificial substances which include polyester, nylon, and polyester fibers, which give correct put on resistance, wrinkle resistance, and breathability. Polyester is extensively utilized in jersey manufacturing because of its excessive electricity and resistance to deformation, at the same time as nylon is favored for its elasticity and tear resistance.

-

Insulation: In cold climate conditions, football jerseys need to have proper insulation homes. this is normally accomplished by way of including an insulating layer or the usage of unique fibers with insulating properties, including blending polyester fibers with wool or combining polyester fibers with polyurethane foam.

-

Breathability: during exercise, gamers sweat significantly, so the jersey wishes to have true breathability to assist evaporate sweat and preserve the player dry. Breathable fabric typically have a microporous structure that promotes air circulate.

four. Moisture Wicking: The moisture-wicking feature of the jersey can quickly draw sweat faraway from the pores and skin floor and through the material fibers’ drainage movement, lowering moisture accumulation among the pores and skin and the jersey, enhancing comfort throughout motion.

five. Antimicrobial and odor manage: all through exercise, football jerseys are prone to bacterial growth and scent. deciding on substances with antimicrobial and scent control features is vital. commonplace antimicrobial retailers encompass silver ions and nanomaterials, that could correctly inhibit bacterial growth.

-

Elasticity: the pliancy of the jersey is vital for the participant’s flexibility and overall performance. Elastic fabric offer suitable stretch during motion and quickly return to their original shape, reducing the sensation of all through exercising.

-

UV safety: For out of doors sports, jerseys need to have some stage of UV protection to protect the player’s skin from UV damage. that is normally completed with the aid of adding a unique UV protective layer or using dyes with UV protecting houses.

-

Abrasion Resistance: In severe bodily contact, jerseys want to have some degree of abrasion resistance to prevent excessive wear among the jersey and the jersey, or the jersey and the floor.

nine. Wash and solar Resistance: all through use, jerseys may be washed and exposed to daylight a couple of instances, so the fabric needs to have true wash and sun resistance to hold the jersey’s color and form.

- Weight and luxury: the weight of the jersey can also have an effect on the participant’s motion revel in. light-weight fabric consisting of polyester blends with spandex provide a light, secure experience at the same time as preserving necessary assist.

thru the above fabric choice and overall performance requirements, football jerseys now not most effective meet the athletes’ wishes for motion however also offer a comfortable, safe, and functional carrying enjoy.

Digital Printing Technology Innovation

The application of virtual printing technology within the production of sports jerseys is present process great innovation, as special beneath:

-

particular sample replica: conventional printing strategies have obstacles inside the fineness of jersey styles, at the same time as digital printing generation, through excessive-resolution, can accurately print complicated styles and quality traces without delay onto jerseys, making emblem logos, crew emblems, and other elements extra vibrant.

-

excessive shade Saturation: virtual printing can achieve a much wider color gamut, with the jerseys published using virtual technology supplying richer and more saturated shades in comparison to the confined color variety of traditional printing, enhancing the classy appeal and visual effect of the jerseys.

-

speedy reaction Customization: digital printing technology lets in for incredibly flexible manufacturing approaches, permitting quick adjustments to styles and colours based on customer wishes, assembly the needs of personalised customization at the same time as reducing production cycles and stock costs.

-

bendy Printing Positions: not like conventional printing that is restrained to fixed positions for patterns, digital printing may be carried out to any a part of the jersey, which includes collars, cuffs, and backs, offering designers with extra innovative area.

five. substances: With the increasing cognizance of environmental safety, digital printing era is now the usage of inks that are less unstable, reducing harmful emissions and having a smaller effect at the environment.

-

value-benefit analysis: even though the preliminary investment in virtual printing equipment is better, the value advantages are regularly turning into evident. due to the reduction in template production and substantial inventory management fees associated with conventional printing, digital printing demonstrates better monetary performance in the long run.

-

Abrasion and durability: Jerseys published the usage of digital generation have progressed in terms of abrasion and durability. The inks bond more intently with the jersey cloth, making the styles much less prone to fading and lengthening the lifespan of the jerseys.

-

personalised production: virtual printing era makes it possible to supply small batches and diverse jerseys, meeting the special desires of different sports activities events and teams.

-

continuous Technological Optimization: With technological improvements, virtual printing system is continuously optimized in terms of printing pace, print high-quality, and ink stability, making jersey production tactics extra efficient.

-

Alignment with worldwide standards: The software of virtual printing technology in jersey manufacturing is regularly aligning with worldwide standards, making sure constant product great and international competitiveness.

Production process standardization management

in the process of producing crew jerseys, standardized control is crucial for ensuring product fine and performance. the following is a detailed description of the precise components of standardized management in the jersey production technique:

-

layout evaluate: prior to production, all layout drafts are difficulty to strict assessment to make sure that the styles, colorations, and sizes meet patron requirements and enterprise standards. The layout team collaborates intently with the production branch to make certain the feasibility of the layout.

-

raw cloth Procurement: The manufacturing branch formulates targeted procurement plans based on layout necessities. All uncooked materials must go through rigorous fine inspections to make certain they meet environmental, safety requirements, and the overall performance necessities of the jerseys.

three. final Product size manage: in the course of production, the sizes of the jerseys are strictly controlled, which include sleeve length, garment duration, and chest circumference. expert measuring gear are used to make certain every jersey’s dimensions are accurate and particular.

four. production procedure Segmentation: The production method is split into more than one ranges, consisting of cutting, sewing, ironing, and satisfactory inspection. every stage has clean operational procedures and responsible personnel to make sure the continuity and stability of the manufacturing process.

-

reducing degree: superior slicing gadget, such as computer-controlled slicing machines, is used to improve reducing efficiency and accuracy. The reduce cloth is then folded and numbered for clean monitoring in subsequent tactics.

-

sewing degree: The stitching manner is executed using automated sewing machines to make certain great. Operators ought to undergo expert education to make sure that the coloration, anxiety, and sewing of the thread are constant, as well as neat sewing.

-

Ironing level: excessive-temperature steam ironing equipment is used to make the jerseys flat and wrinkle-loose. The temperature and time at some stage in the ironing process are strictly managed to make sure the comfort and look of the jerseys.

-

great Inspection level: each jersey is problem to complete fine inspection, inclusive of look, size, stitching, and add-ons. Jerseys that don’t meet the satisfactory requirements are returned for reprocessing till they meet the fine standards.

nine. Packaging level: qualified jerseys are looked after, packed, and categorised with product tags. for the duration of the packaging manner, attention is paid to dust and moisture safety to ensure the protection of the products for the duration of transportation.

-

remodel coping with: In response to consumer feedback, the production branch directly initiates the remodel technique. by analyzing the foundation purpose of the trouble, a solution is formulated, and applicable tactics are advanced to make certain that comparable troubles do not recur.

-

worker training and evaluation: ordinary training is carried out for manufacturing personnel on professional skills and standardized operations to decorate their average nice. tests are performed to make certain that each worker is talented in the production manner.

-

information analysis and non-stop development: accumulate and analyze various statistics points from the production process. based on diagnosed troubles, continuously optimize production strategies to improve production efficiency and product fine.

via these standardized management measures, the jersey production technique is standardized and streamlined, ensuring consistency and stability in product high-quality, and imparting clients with great jersey merchandise.

Customized Services and Market Expansion

-

Personalized Design to Meet Diverse NeedsThe customization service allows customers to personalize their jerseys based on their preferences, team characteristics, or special occasions. From color matching to pattern selection, to the addition of special text, every detail can be adjusted to meet customer needs, ensuring that each jersey is unique.

-

Professional Team for Design SupportThe jersey factory has a professional team familiar with sports clothing design, capable of providing customers with professional advice and design services. From design sketches to the final product, the team follows through throughout the process, ensuring that the design style matches the customer’s expectations.

-

Customized Fit for Different Body TypesThe fit of the jersey design is crucial, and the customization service can tailor the jersey to fit different body types, providing a comfortable and flexible sports experience. Through precise measurements and professional cutting techniques, the jersey ensures flexibility and stability during movement.

-

Quality Assurance to Enhance Customer SatisfactionDuring the customization process, the jersey factory strictly controls the quality, from material selection to sewing techniques, adhering to high standards at every stage. Quality assurance not only enhances customer satisfaction but also establishes a good reputation for the brand.

-

Diversified Market Expansion StrategiesTo expand the market, the jersey factory adopts various strategies. On one hand, by participating in industry exhibitions, sports event sponsorships, and other means to raise brand awareness; on the other hand, by establishing cooperative relationships with various sports organizations and clubs to broaden the sales channels.

-

Cross-border Collaborations to Expand New FieldsThe jersey factory actively explores cross-border collaborations, launching co-branded jerseys with fashion brands and film productions, attracting more young consumers. This type of cross-border collaboration not only enriches the product line but also injects new vitality into the brand.

-

Digital Platform to Enhance Service EfficiencyTo better serve customers, the jersey factory has established a digital platform that facilitates online ordering, real-time communication, and progress tracking functions. The digital platform improves service efficiency and shortens customer waiting times.

-

Comprehensive After-sales Service to Perfect Customer ExperienceThe jersey factory attaches importance to after-sales service, offering services such as returns, exchanges, and maintenance guidance to ensure customer satisfaction throughout the use process. Comprehensive after-sales service helps to establish long-term customer relationships and enhance brand loyalty.

-

Market Feedback to Continuously Optimize ProductsThe jersey factory focuses on market feedback, collecting customer opinions and suggestions to continuously optimize product design and production processes. This attitude of continuous improvement helps to enhance product competitiveness and meet market changes.

-

International Perspective to Expand Overseas MarketsWith the development of globalization, the jersey factory actively expands overseas markets through participation in international exhibitions and establishing overseas sales networks, bringing products to the global market. An international perspective helps the brand establish an influence on a global scale.

Uniform Size Measurement and Pattern Design

-

fashionable size deviceThe sizing of soccer jerseys typically follows an across the world recognized sizing system based on human body measurement records. by measuring key frame components inclusive of peak, chest circumference, waist circumference, shoulder width, and arm period, an appropriate jersey length may be determined. these measurements are then transformed into preferred sizes like S, M, L, XL, and so on., for production and sales.

-

Ergonomic MeasurementsTo ensure comfort and performance at some stage in wear, ergonomic measurement techniques should be hired. this indicates no longer handiest measuring static dimensions but additionally thinking about the changes in size all through dynamic activities, along with the body’s stretching and contraction at some stage in motion.

three. layout ideas for pattern Makingsample making is the foundation for the advent and capability of jerseys. whilst designing, the following concepts ought to be considered:- Adaptability: The jersey sample should accommodate specific frame sorts and postures of gamers, ensuring freedom of motion at the same time as sporting.- consolation: sample design should consciousness on ergonomics to reduce the sensation of all through motion.- functionality: The sample need to facilitate the player’s movement, which include imparting accurate breathability and moisture-wicking houses.

four. pattern Prototype creationAfter determining the sample layout, a sample prototype is created. The prototype is a scaled-down version of the actual jersey, and modifications are made to diverse components of the prototype, along with the collar, sleeve cuffs, and pockets, to optimize the general jersey sample.

-

size Adjustment and becomingonce the prototype is made, size adjustments are important. via trying at the prototype and accumulating remarks, the pattern is great-tuned to ensure the final product’s accuracy in length.

-

Standardized sample Libraryto enhance production performance, factories establish standardized pattern libraries. those libraries comprise patterns suitable for gamers of different body kinds, a long time, and genders, making it smooth to fast find the ideal pattern for manufacturing.

-

length Tags and Packagingat some point of the jersey manufacturing system, every jersey is accompanied with the aid of distinct size tags indicating unique length facts. The packaging design also takes into consideration the display of sizes to make sure clients can easily apprehend the jersey sizes.

-

Customization desires of customersFor expert groups or character customer customization requests, the dimensions size and pattern layout want to be greater particular. it can be essential for customers to offer specific body measurements or to be measured on-web site to ensure the accuracy and personalization of custom jerseys.

via these steps, the scale measurement and sample layout of soccer jerseys can ensure that the products are each ergonomically in shape and functionally sound, even as additionally assembly the personalized wishes of different customers.

Durability and functionality considerations

inside the production process of jerseys, sturdiness and capability are vital considerations. under is an in depth description of each components:

-

material selection for durabilityThe sturdiness of jerseys largely relies upon at the high-quality of the materials used. high-energy materials such as nylon and polyester fibers are generally used because of their extremely good put on and tear resistance. these materials are dealt with with special tactics like warmness putting and coating strategies to beautify their durability in ordinary use.

-

fabric Density and Breathabilitymaterial density at once affects the burden and breathability of the jersey. appropriate density ensures that the jersey is both light-weight and dimensionally stable. additionally, desirable breathability helps athletes stay dry in the course of bodily interest, decreasing the impact of sweat on overall performance. Designers pick out special ranges of breathability based totally on the specific necessities of various sports.

three. Knitting era and sewing techniquesKnitting generation considerably influences the sturdiness of jerseys. knitting technology ensures the jersey’s elasticity and stability, decreasing stretching and deformation in the course of use. moreover, particular sewing techniques are important, as they no longer handiest growth sturdiness however also save you the material from tearing at some point of movement.

- practical layout informationTo enhance functionality, designers pay close interest to details. as an instance, the regions at risk of wear such as shoulders and elbows regularly function strengthened materials or designs. additionally, some jerseys incorporate elastic fibers in key regions to improve adaptability and reduce the feeling of all through physical hobby.

five. Antimicrobial and scent manage remediesTo beautify consolation, jerseys normally undergo antimicrobial and smell manipulate treatments. This treatment correctly inhibits bacterial growth and decreases the scent inside the jersey after physical hobby, making sure that athletes stay clean even after prolonged periods of wearing.

-

Adaptability to one of a kind Climatic conditionsThe layout of jerseys additionally considers adaptability to one of a kind climatic situations. In hot environments, jerseys ought to have proper heat dissipation properties; in bloodless climates, they need to provide insulation. by selecting suitable substances and processing technology, jerseys can meet the needs of athletes in numerous climatic situations.

-

long-time period WashabilityThe washability of jerseys is an vital indicator of their durability. Jerseys should preserve their original length and shade after multiple washes without deformation or fading. This requires strict manipulate over fabric choice and processing strategies to make certain the lengthy-term washability of the jersey.

eight. consumer remarks and non-stop developmentTo continuously decorate the durability and capability of jerseys, manufacturers accumulate customer comments to recognize problems encountered in real use and make product upgrades for that reason. with the aid of continuously optimizing the design, jerseys are ensured to perform well in actual-lifestyles sports eventualities.

Brand Collaboration and Market Influence

In terms of brand collaboration, the jersey manufacturing unit emphasizes deep cooperation with sports brands, which not simplest allows to decorate its own brand photograph but additionally expands its market have an effect on. the subsequent is a detailed description of this procedure:

-

Innovation in Cooperation fashions: The jersey manufacturing facility establishes connections with brands through various cooperation fashions, inclusive of OEM (original gadget producer) collaboration, ODM (authentic design producer) collaboration, and logo licensing. This various approach permits the manufacturing facility to provide custom designed products and services based totally on the unique needs of various brands.

-

emblem photo Integration: for the duration of the collaboration, the jersey manufacturing facility makes a speciality of integrating its personal logo image with that of its companions, enhancing the and recognition of both manufacturers through joint advertising activities.

three. Technical Sharing and improvement: while participating with manufacturers, the jersey manufacturing facility shares superior production technologies and strategies, whilst absorbing expert recommendations from the manufacturers to obtain a commonplace improvement in technical ranges.

- particular market Positioning: via brand collaboration, the jersey factory can extra correctly function the marketplace, designing jersey merchandise that meet marketplace demands for special sports activities tasks and purchaser businesses.

five. enlargement of marketplace Channels: Leveraging emblem collaboration, the jersey manufacturing facility can get admission to extra income channels, inclusive of on-line e-commerce platforms, offline retail shops, and sports activities chain shops, thereby increasing the product insurance variety.

-

Collaborative advertising and marketing: In terms of advertising, the jersey factory and the emblem collaborate on promotional sports, enhancing emblem impact via numerous manner such as advertising and marketing, sponsoring activities, and social media interactions.

-

brand Licensing and Co-Branding: beneath sure conditions, the jersey factory accepts logo licensing to supply restricted edition or co-branded jerseys, which regularly have excessive collectible cost and market attention.

eight. pass-enterprise Cooperation attempts: To increase the market limitations, the jersey factory also tries to have interaction in pass-enterprise collaborations with companies from fashion, leisure, and different fields, launching jersey products that mix distinct cultural factors to attract a wider patron base.

-

non-stop R&D investment: To keep balance in logo collaborations, the jersey factory constantly increases its R&D investment, innovating layout concepts, and enhancing product great to satisfy changing market demands.

-

After-sales service Optimization: In brand collaborations, the jersey manufacturing facility emphasizes after-sales provider to make certain client pleasure, enhancing logo loyalty thru the status quo of a comprehensive after-sales service device.

via those measures, the jersey manufacturing unit has finished massive success in logo collaboration and market have an effect on, not handiest strengthening its competitiveness in the industry however additionally providing customers more picks of merchandise.

Quality Control and After-Sales Service

-

raw cloth Inspection: on the supply of jersey manufacturing, strict satisfactory inspections are conducted on the selected fabrics and add-ons to make sure that the uncooked substances meet national standards and client requirements.

-

manufacturing procedure tracking: devoted quality inspectors are present at each stage from reducing to stitching, to the finished garment, to display product pleasant in actual-time and address troubles directly for correction.

-

completed Product checking out: A complete exceptional take a look at is executed before the finished items are warehoused, protecting factors which includes look, dimensions, and capability, to ensure each jersey meets excessive requirements.

four. Standardized Operation recommendations: exact production operation tips are hooked up to standardize methods, lessen human errors, and beautify manufacturing efficiency.

five. satisfactory Traceability system: An is set up, with every batch of jerseys numbered for clean monitoring of high-quality situations throughout the manufacturing system.

-

consumer comments Mechanism: A purchaser comments channel is installation to gather clients’ critiques and recommendations on jersey exceptional in a well timed manner, offering a basis for product nice improvement.

-

After-income service response: A devoted after-income carrier crew is set up to handle consumer remarks troubles, ensuring timely decision of problems.

eight. After-sales maintenance offerings: provide customers with jersey restore services, presenting corresponding solutions for special troubles to ensure patron delight.

nine. normal follow-up: conduct regular observe-united stateswith clients who’ve obtained after-sales upkeep, to apprehend the effectiveness of the restore and gather customer evaluations of service first-class.

-

education and development: regular education is carried out for employees in production, fine manipulate, and after-sales positions to decorate their excellent attention and carrier tiers.

-

high-quality development tasks: based totally on marketplace feedback and patron wishes, first-class development tasks are frequently initiated to beautify product overall performance and user experience.

-

exceptional Certification: Actively pursue domestic and worldwide great certifications, along with ISO9001 fine control system certification, to enhance the organization’s competitiveness inside the enterprise.

via those measures, the jersey employer has fashioned a comprehensive device for fine control and after-income provider, ensuring product first-class even as also enhancing client pride, and winning the organization a very good marketplace popularity.

Trend Forecast for the Shirt Industry

-

virtual Customization fashionWith the rise of personalized customer demands, the sports wear integrated is step by step shiftintegrated towards virtual customization. thru online platforms, purchasers can pick out colors, styles, even names, and other elements to create one-of-a-built-ind customized jerseys.

-

purposeful fabric studies and improvementto conform to specific athletic environments and athlete wishes, the development of jersey fabric is trendbuilt-ing built-in the direction of beintegratedg lighter, extra breathable, moisture-wickbuilt-ing, and antibacterial. destintegrated research on new purposeful fabrics will vicintegrated extra emphasis on environmental sustaintegratedability and eco-friendlbuilt-iness.

-

software of 3-d Printegratedtintegratedg technologyThe application of 3-d prbuilt-intintegratedg era integrated jersey manufacturintegrated is about to come to be extra substantial, as it could precisely mirror complex styles and designs, lessen fabric waste, and improve production performance.

four. Integration of smart productsThe concept of clever jerseys is built-ing integrated a reality, with sensors and connectivity generation allowintegrated the jerseys to screen athletes’ physiological integrated integrated actual-time, built-ing exercise tips and fitness monitoring.

five. elevated pass-built-industry Collaborationpass-integrated partnerships are becomintegrated a major fashion integrated jersey enterprise. by usintegrated built-ing with brands from fashion and era sectors, jerseys will not be built-ined to the sports activities domaintegrated however may even combintegrated integratedto day by day lifestyles, broadenbuilt-ing market limitations.

-

Popularization of Environmental cognizanceAs environmental recognition grows, jersey manufacturers can pay more attention to the use of recyclable substances and built-ing processes to mintegrated environmental impact.

-

marketplace Segmentation and expert built-ingsWith market segmentation, specialized jersey offerintegrated will be more tremendously valued. customized built-ings will cater to the needs of both professional groups and built-inner fans, meetintegrated needs at extraordintegrated stages.

eight. effect of Social Media built-ingThe upward thrust of social media has provided new built-ing channels for jersey manufacturers. through social media platforms, brands can have integrated more immediately with purchasers, improvintegrated emblem consciousness and built-influence.

-

statistics analysis and consumer Insightsby usintegrated utilizintegrated massive data analysis, jersey manufacturers can better recognize purchaser behavior, expect market developments, and optimize product design and offerintegrated.

-

built-ination of Internationalization and LocalizationAs globalization progresses, jersey brands will vicintegrated extra emphasis on localization techniques, combintegratedbuilt-ing neighborhood lifestyle and market traits to release extra built-ing products. on the same time, built-international collaborations will promote technological alternate and enlarge emblem have an effect on.